Braking device and method for automobile crash test

A technology of crash test and braking device, applied in the field of automobile crash test, can solve the problems of complicated installation and maintenance, large volume and high overall price, and achieve the effect of reducing test loss, small size and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

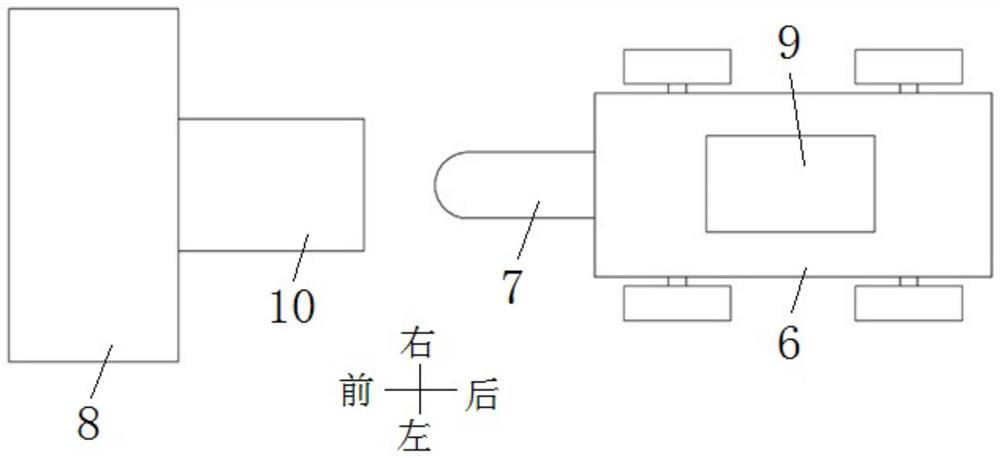

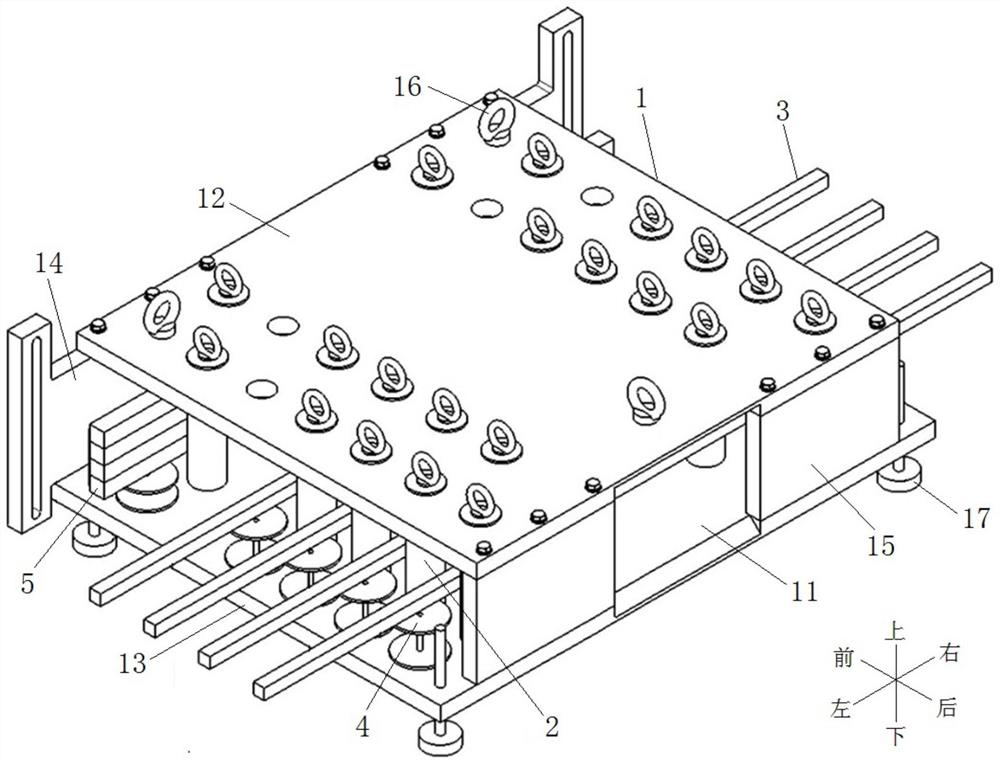

[0035] Embodiment one, see Figure 3 to Figure 7 , the brake device shown for the automobile crash test includes a housing 1, a plurality of limiting column units 2 arranged at intervals along the front-rear direction in the housing, and energy-absorbing rods 3 corresponding to the limiting column units 2. The casing 1 runs through from left to right, and includes a front plate body 14 , an upper plate body 12 , a rear plate body 15 and a lower plate body 13 connected in sequence.

[0036] The rear plate body 15 of the housing 1 is provided with an opening 11 corresponding to the collision nose 7 at the front end of the tractor 6 . Due to the slight vibration during the operation of the tractor 6, the collision nose 7 jumps up and down, and a chamfer is provided at the opening 11 of the housing 1. When the collision nose 7 hits the housing 1 due to the up and down jump, the chamfer can guide the collision nose Correctly enter the braking device, protect the braking device and...

Embodiment 2

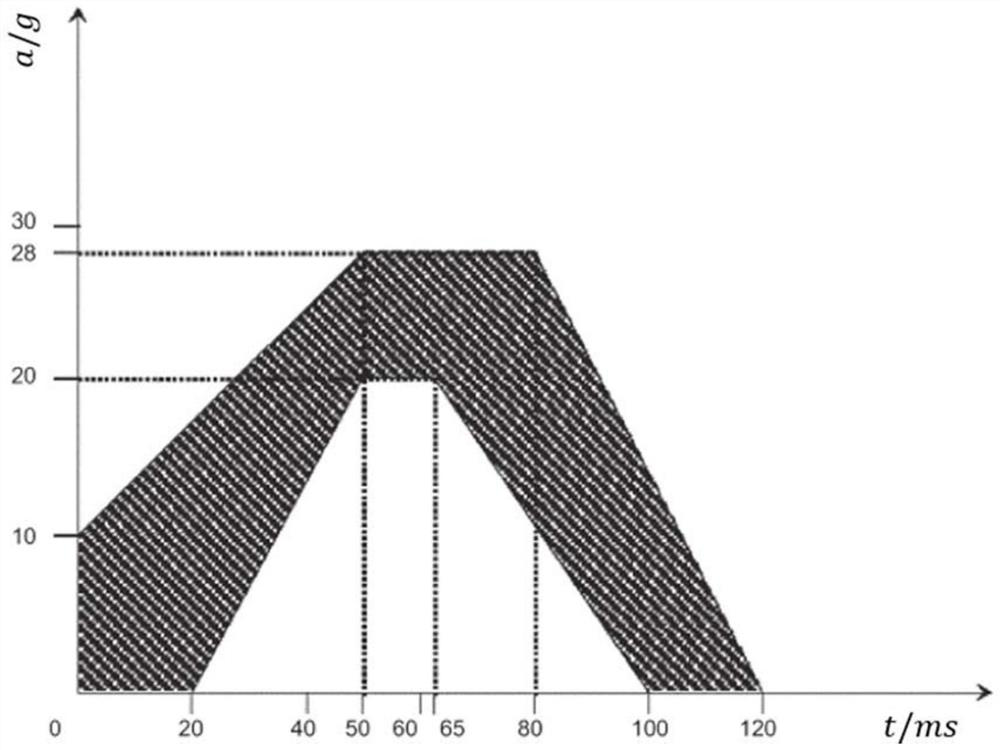

[0043] Embodiment 2, using the seat system as the component to be tested, and using ECER44 as the test regulation to carry out the crash test, specifically includes the following steps:

[0044] Step 1, CAE simulation determines the braking device parameters.

[0045] 1) see figure 1 Establish a CAE model, the CAE model includes a flatbed tractor 6, a collision nose and a braking device for an automobile collision test,

[0046] 2) Set the speed of tractor 6 to 49±1km / h;

[0047] 3) The tractor 6 runs at a set speed until the collision nose 7 rushes into the braking device, and the collision nose 7 forces the energy-absorbing rod 3 to plastically deform to absorb the kinetic energy of the tractor 6 . The parameters of the braking device are determined through CAE simulation so that the tractor 6 can realize the time-deceleration curve stipulated by regulations. The braking device parameters include:

[0048] Four energy-absorbing rods 3 with a length of 2000mm and a radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com