Double-station processor capable of achieving uniform exhaust and exhaust method of double-station processor

A dual-station, processor technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve the problems affecting the uniformity of gas distribution on the surface of semiconductor substrates, different pressures, and reducing the qualified rate of semiconductor substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

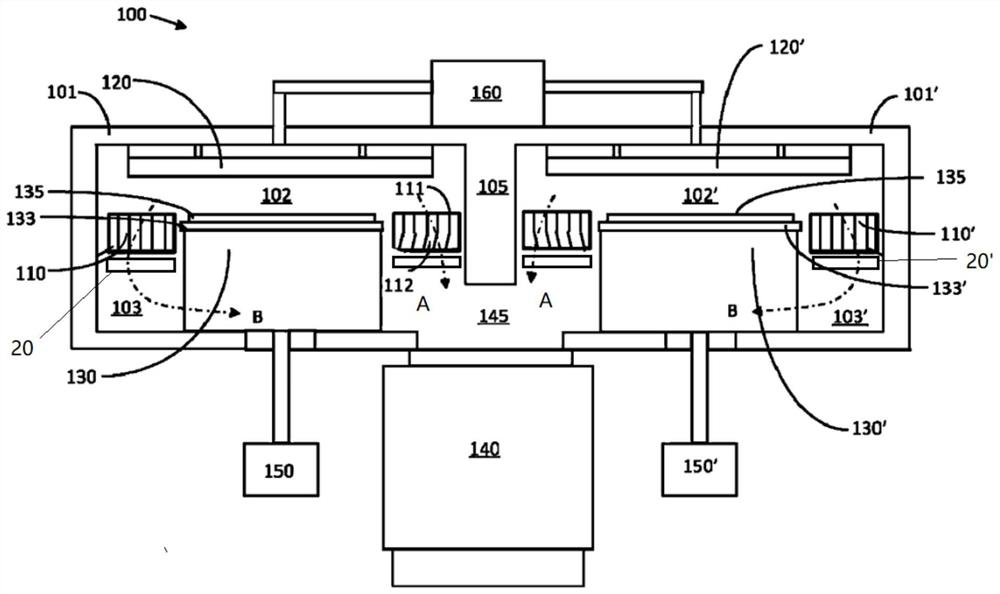

[0029] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

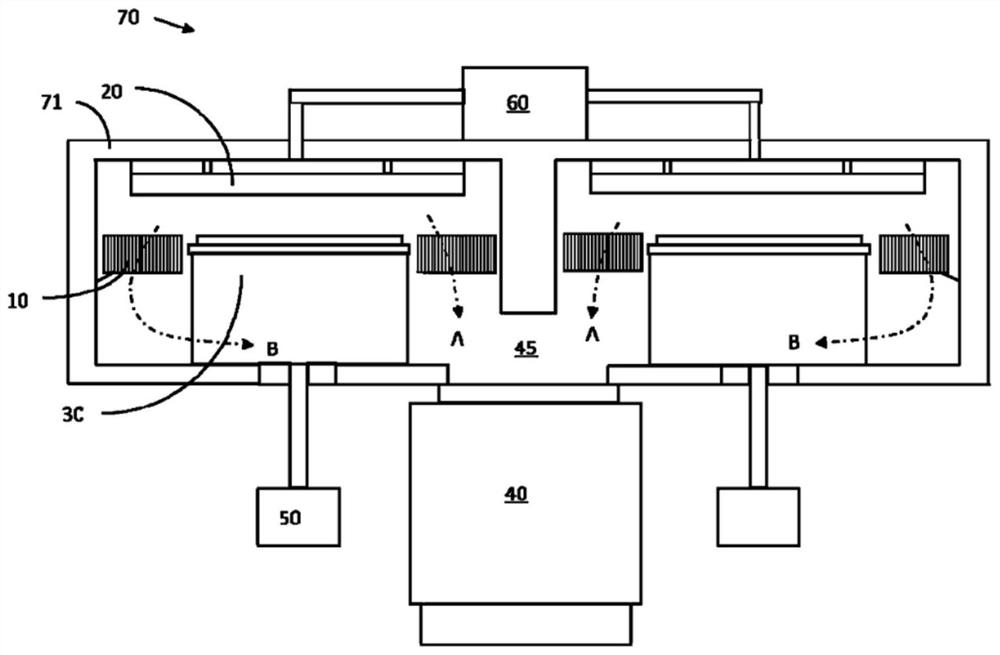

[0030] figure 2 It shows a cross-sectional view of a plasma processing device with double reaction chambers provided according to an embodiment of the present invention. In another embodiment, the number of reaction chambers of the plasma processing device may be more than two, and its working principle and exhaust The structure is similar to the double reaction chamber structure.

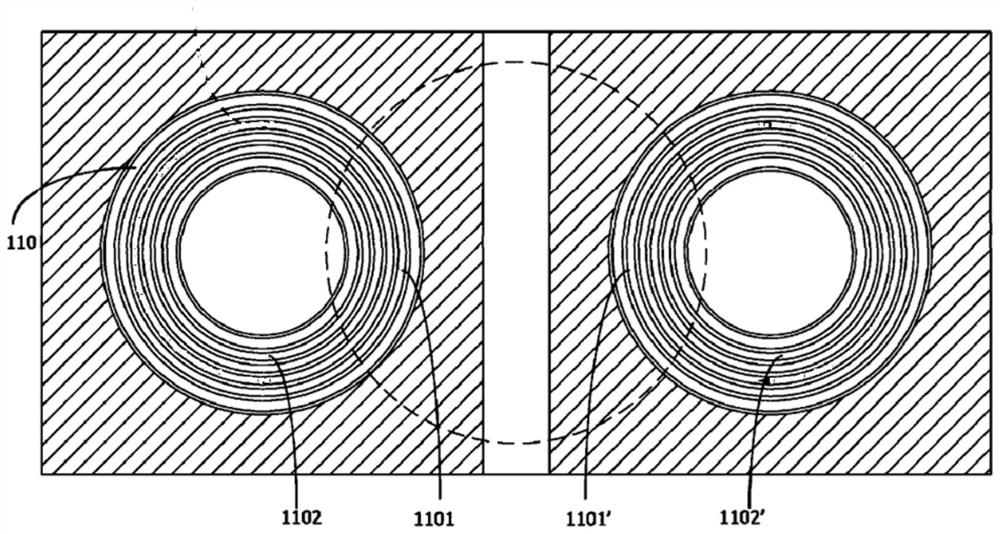

[0031] exist figure 2 The shown plasma reactor 100 includes two reaction chambers arranged adjacent to each other. The two reaction chambers are respectively surrounded by reaction chamber walls 101 and 101', and are provided with an adjacent side wall 105. During the process, the plasma reactor 100 is usually set in a vacuum environment. When the process starts, a gas injection device injects the reaction gas in the reaction gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com