Motor paint spraying production line and using method thereof

A production line and jet head technology, which is used in painting booths, manufacturing motor generators, and electric components, etc., can solve the problems of human injury and high labor intensity, and achieve the effect of reducing injury, reducing labor intensity and improving physical safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

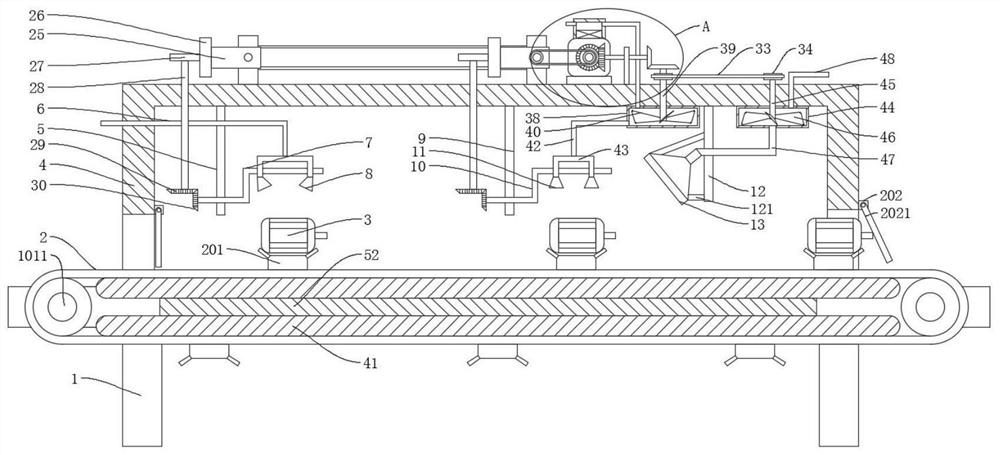

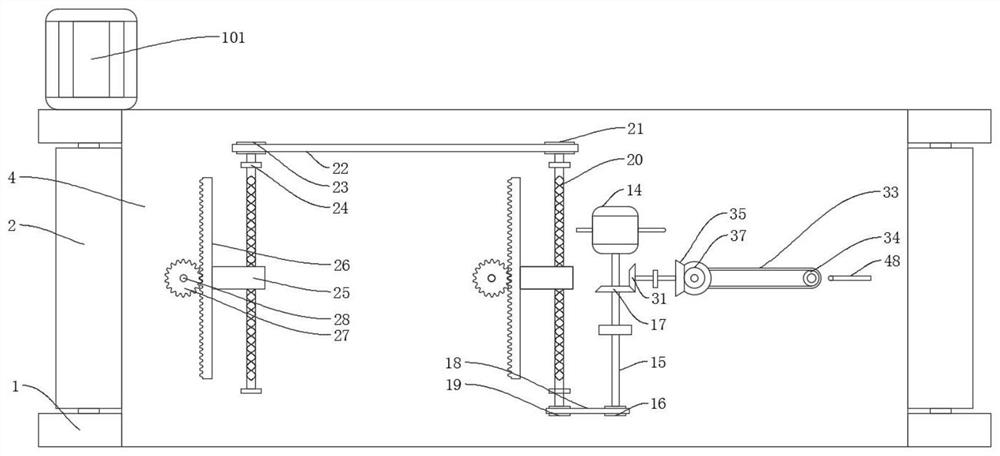

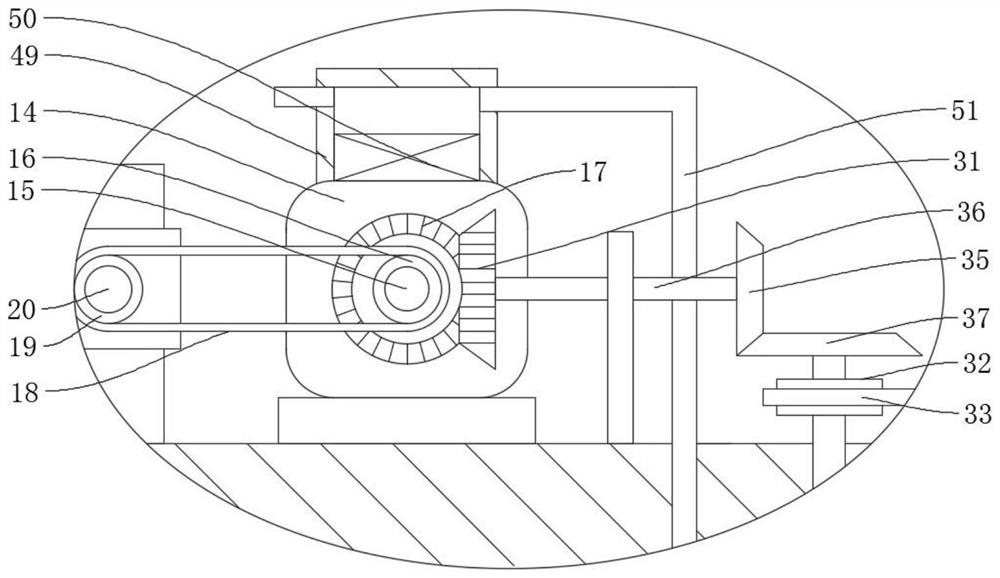

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , a motor painting production line, including a workbench 1, a conveyor belt 2, a paint spraying mechanism, a drying mechanism, an exhaust mechanism and a painted part 3, the conveyor belt 2 is rotatably connected to the workbench 1, and the painted parts 3 are placed on the conveyor belt 2 , the workbench 1 is fixedly connected with a protective cover 4, the painting mechanism, the drying mechanism and the exhaust mechanism are all fixedly connected on the protective cover 4, and the protective cover 4 is fixedly connected with a driving mechanism, and the driving mechanism is connected with the painting mechanism and the drying mechanism. It is rotatably connected with the exhaust mechanism.

[0033] The painting mechanism includes a first fixed plate 5, a paint spray pipe 6, a first Z-shaped plate 7, and a paint spraying head 8. The first fixed plate 5 is fixedly connected to the protective cover 4, and the firs...

Embodiment 2

[0043] refer to figure 1 , a motor painting production line, including a workbench 1, a conveyor belt 2, a paint spraying mechanism, a drying mechanism, an exhaust mechanism and a painted part 3, the conveyor belt 2 is rotatably connected to the workbench 1, and the painted parts 3 are placed on the conveyor belt 2 , the workbench 1 is fixedly connected with a protective cover 4, the painting mechanism, the drying mechanism and the exhaust mechanism are all fixedly connected on the protective cover 4, and the protective cover 4 is fixedly connected with a driving mechanism, and the driving mechanism is connected with the painting mechanism and the drying mechanism. It is rotatably connected with the exhaust mechanism.

[0044] The painting mechanism includes a first fixed plate 5, a paint spray pipe 6, a first Z-shaped plate 7, and a paint spraying head 8. The first fixed plate 5 is fixedly connected to the protective cover 4, and the first Z-shaped plate 7 is rotatably connec...

Embodiment 3

[0054] An operation method of a motor painting production line, which adopts the following steps:

[0055] S1, start the second motor 101, the second motor 101 drives the conveyor belt 2 to rotate through the third rotating shaft 1011, and puts the painted part 3 on the placement seat 201 on the conveyor belt 2 into the protective cover 4 for painting;

[0056] S2, move the painted part 3 to the bottom of the painting head 8, stop the rotation of the second motor 101, then start the first motor 14, the first motor 14 drives the first Z-shaped plate 7 to rotate through the first transmission mechanism, and passes through the paint spraying pipe 6 Transport the spray paint into the paint spray head 8 to spray paint on the painted parts 3, and the first Z-shaped plate rotates back and forth at 180 degrees to spray paint in all directions on the painted parts 3, so as to improve the uniformity of painting;

[0057] S3, start the second motor 101 after the painting is completed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com