Dual-motor hybrid power drive system for rear drive

A technology of hybrid power and drive system, which is applied to the layout of multiple prime movers, power devices, and air pressure power devices of general power devices, and can solve the problems of limited fuel saving rate, large pollutant discharge, and fuel saving effect. no problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

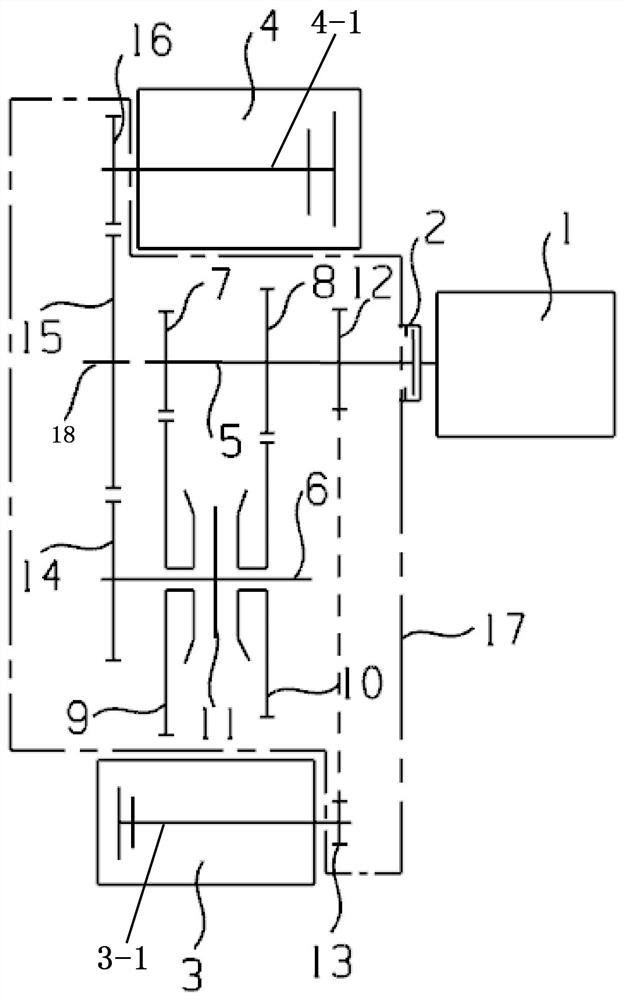

[0017] Example 1, as figure 1 As shown, when a synchronizer 11 is arranged between the first-speed driven gear 9 and the second-speed driven gear 10, the synchronizer 11 is circumferentially fixed on the intermediate shaft 6, the first-speed driving gear 7, the second-speed driving gear 8 are circumferentially fixed on the input shaft 5, the first-speed driven gear 9 and the second-speed driven gear 10 are clearance-fitted on the intermediate shaft 6, and the first-speed driven gear 9 and the second-speed driven gear 10 face each other. One end is respectively provided with engaging teeth, and the ring gear of the synchronizer 11 corresponds to the engaging teeth of the first-speed driven gear 9 and the second-speed driven gear 10 respectively, so that the synchronizer 11 is connected to the corresponding first-speed driven gear 9 or second-speed The driven gear 10 is engaged to complete the power transmission between the input shaft 5 and the intermediate shaft 6, and realize...

Embodiment 2

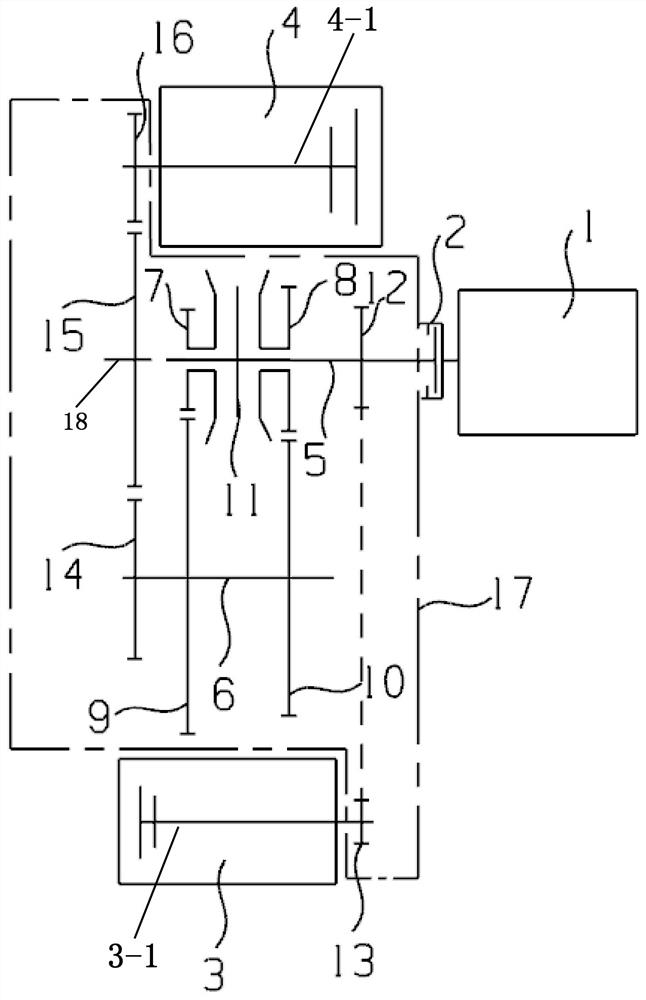

[0018] Example 2, as figure 2As shown, when a synchronizer 11 is arranged between the first-speed driving gear 7 and the second-speed driving gear 8, the synchronizer 11 is circumferentially fixed on the input shaft 5, and the first-speed driving gear 7 and the second-speed driving gear 8 are respectively The first-speed driven gear 9 and the second-speed driven gear 10 are respectively fixed on the intermediate shaft 6 in the circumferential direction, and the first-speed driving gear 7 and the second-speed driving gear 8 are respectively arranged at the opposite ends. Engagement teeth, the ring gear of the synchronizer 11 corresponds to the engaging teeth of the first-speed driving gear 7 and the second-speed driving gear 8 respectively, so that the synchronizer 11 is engaged with the corresponding first-speed driving gear 7 or the second-speed driving gear 8, and the completion is completed. The power transmission between the input shaft 5 and the intermediate shaft 6 real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com