Transporting device for glass tubes and transporting method of transporting device

A technology of transportation device and glass tube, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., which can solve problems such as inconvenient production efficiency, glass tube damage, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

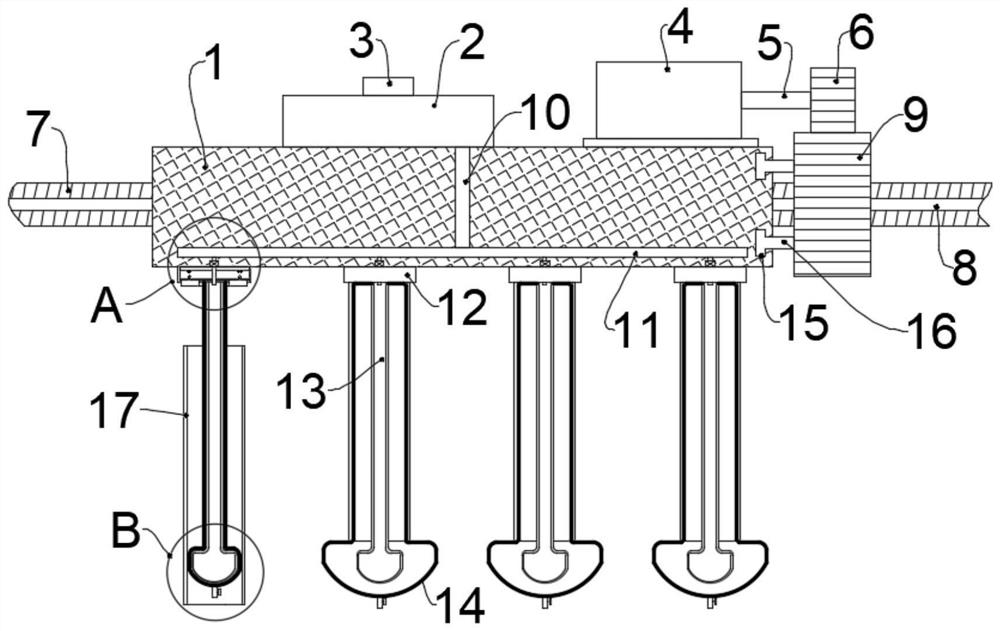

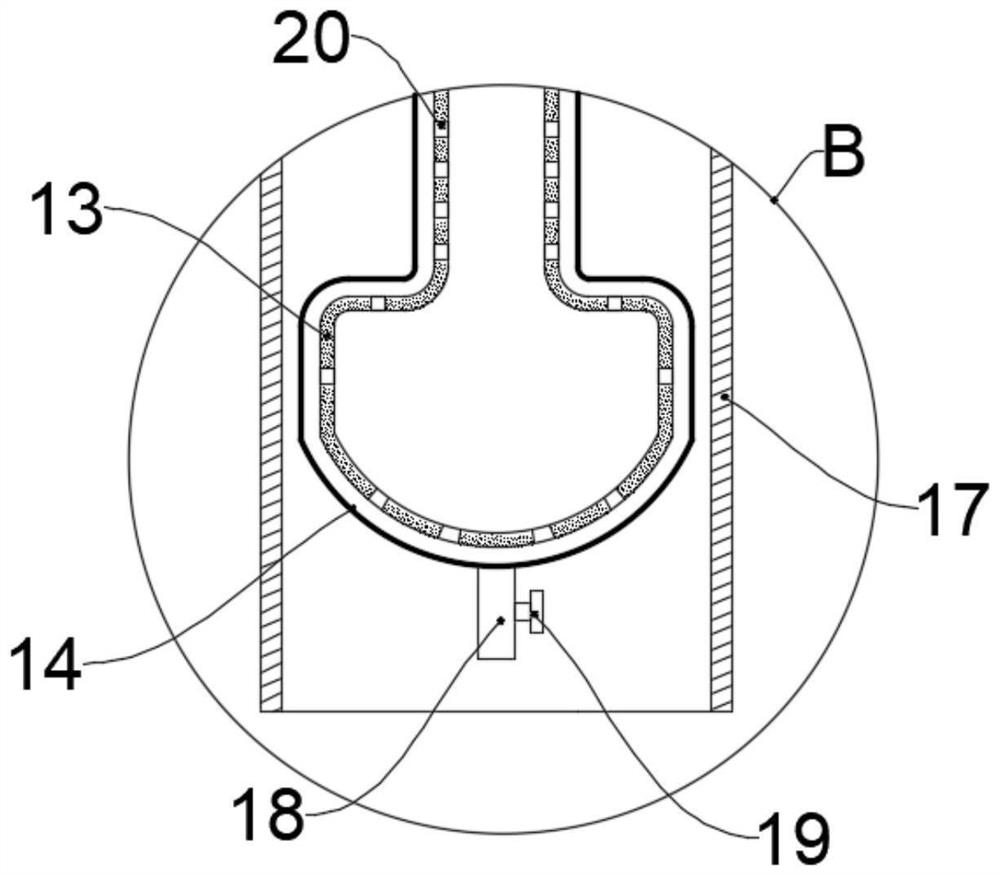

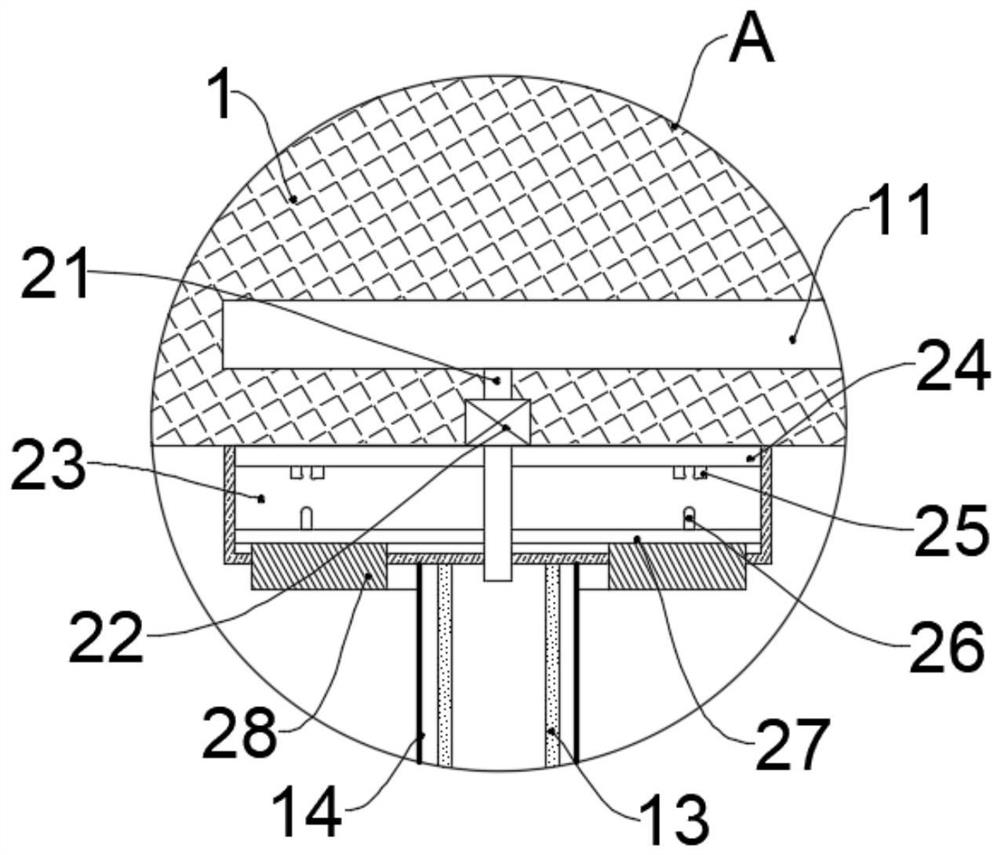

[0030] Such as Figure 1-5 As shown, a transportation device for glass tubes includes a moving block 1, a plurality of connecting blocks 12 are equidistantly arranged on the lower side of the moving block 1, the connecting blocks 12 are vertically arranged with the moving block 1, and the lower side of the connecting block 12 An insertion rod 13 is provided, and an air bag 14 is provided on the outside of the insertion rod 13. The air bag 14 is made of nylon cloth, and the air bag 14 can shrink to the outside of the insertion rod 13. A glass tube 17 is sleeved, and the air bag 14 can be attached to the inner wall of the glass tube 17 when it is inflated. The ring side of the insertion rod 13 is provided with a plurality of air guide holes 20 for transmitting gas. The upper end of the insertion rod 13 An air guide branch pipe 21 is provided, and the upper end of the air guide branch pipe 21 passing through the connection block 12 is provided with a gas guide main pipe 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com