Application of polyester amide as high-temperature-resistant heat-shrinkable film

A technology of polyester amide and heat shrinkable film is applied in the application field of polyester amide as heat shrinkable film, which can solve the problems of poor heat resistance of heat shrinkable film and achieve the effect of realizing shrinkage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of heat-shrinkable film 1 specifically comprises the following steps:

[0046] Take 22.4g of tall oil-based dimer acid, 3.4g of 1,3-diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat them for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 1.

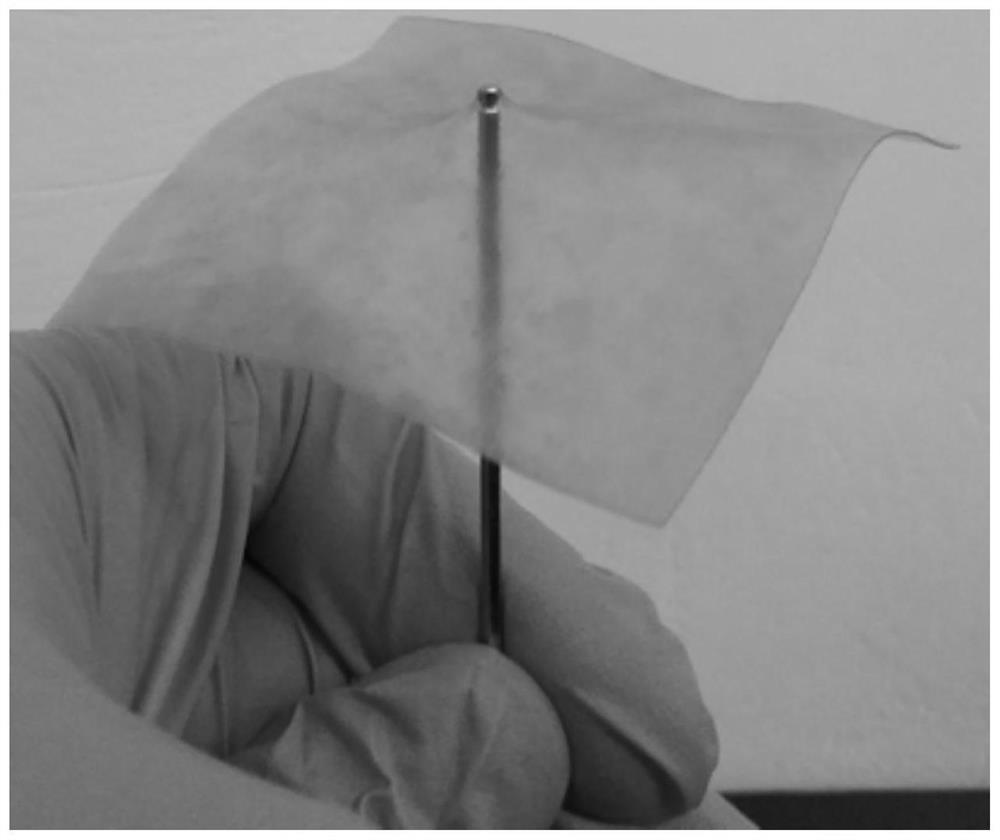

[0047] The polyester amide 1 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 1.

Embodiment 2

[0049] The preparation of heat-shrinkable film 2 specifically comprises the following steps:

[0050]Take 20.8g of tall oil-based dimer acid, 3.4g of 1,3 diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat them for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 2.

[0051] The polyester amide 2 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 2.

Embodiment 3

[0053] The preparation of heat-shrinkable film 3 specifically comprises the following steps:

[0054] Take 19.2g of tall oil-based dimer acid, 3.4g of 1,3 diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 3.

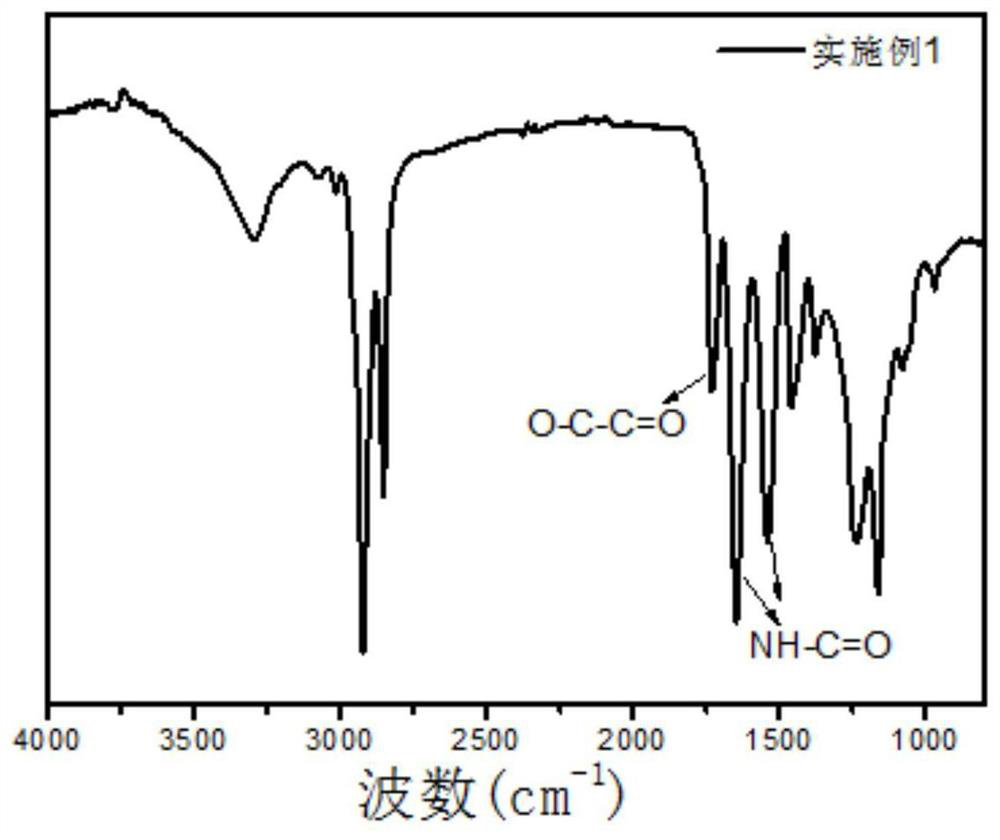

[0055] The polyester amide 3 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 3 . Such as figure 1 Shown: After the raw material tall oil-based dimer acid of the present invention is reacted according to Example 1, the carboxyl peak basically disappears, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com