Divided feeding pipeline for distiller's yeast

A technology for feeding pipelines and distiller's mother, applied in biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as high bacterial contamination, dead corners that are difficult to clean, and affect the processing effect of distiller's mother

Pending Publication Date: 2021-06-08

江苏罗迈特生物科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the particularity of the distiller's own characteristics, the pipelines for processing and feeding materials need to be cleaned and sterilized. However, the existing pipelines are difficult to clean due to the large number of pipelines, and the probability of bacterial contamination is high, which affects the processing effect of the distiller's mother.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Next, the technical solutions in the embodiments of the present invention will be described in the following examples, and the described embodiments are merely, and embodiments are intended to be, in rather than all embodiments. Embodiments in the present invention, all other embodiments obtained without making creative labor have not made creative labor premises.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

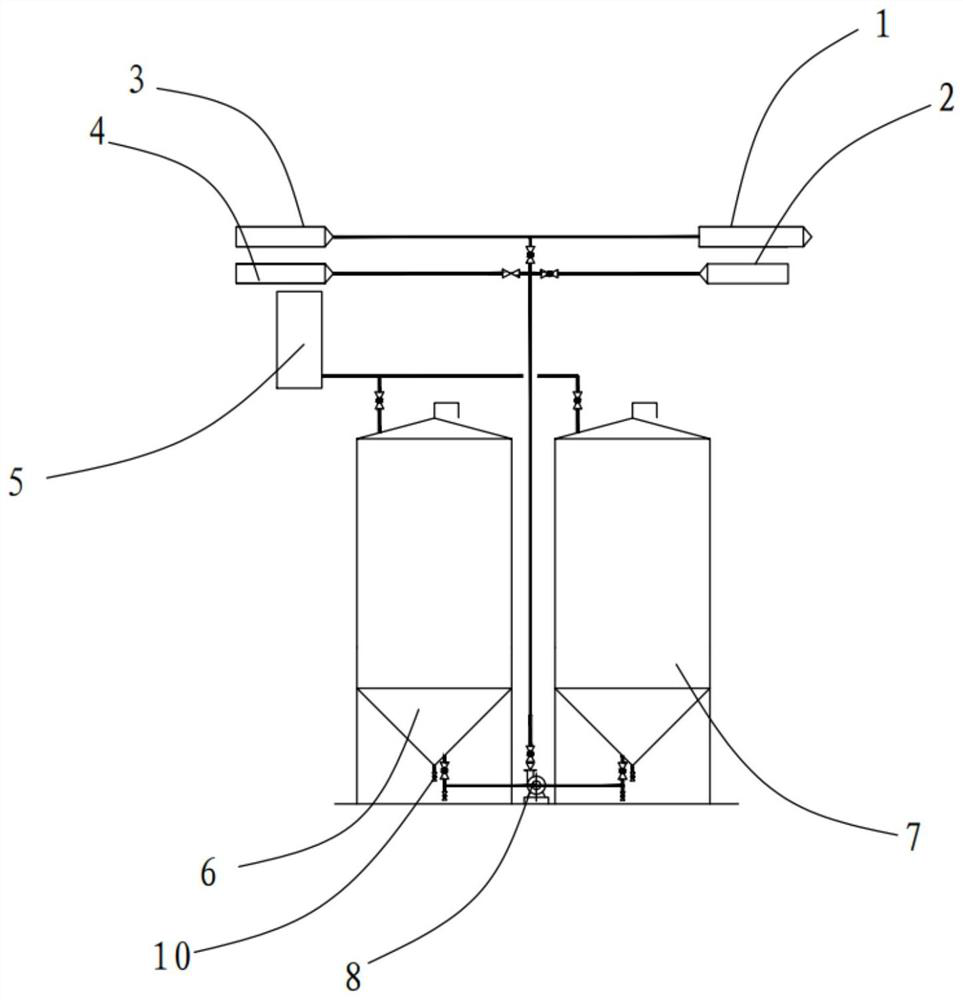

The invention provides a divided feeding pipeline for distiller's yeast, which comprises a first distiller's yeast tank, a second distiller's yeast tank, a feeding pipeline communicated with the first distiller's yeast tank and the second distiller's yeast tank, a ball valve arranged on the feeding pipeline, a distiller's yeast pump connected with the feeding pipeline, a saccharifying pot communicated with the distiller's yeast pump, a steam main pipe used for pipeline sterilization and a technical water pipe connected with the steam main pipe. According to the invention, the optimized pipeline adopts a design of divided feeding, the problems of pipeline disinfection and cleaning are fully considered, dead angles are reduced to the maximum extent, the contamination probability is reduced, and disinfection steam and drugs are saved, so that the production cost is effectively saved.

Description

Technical field [0001] The present invention relates to the field of alcohol processing, and more particularly to an alcohol-to-use feed line. Background technique [0002] Yeast is needed to expand the culture in alcohol processing to obtain a yeast culture solution containing a sufficient amount of yeast, which contains a large amount of yeast fluid, referred to as alcohol. And the expandation of this yeast is called the preparation of the wine mother. Due to the particularity of the liquid mother's own characteristics, the piping of the processing is required to ensure cleaning and sterilization, while the existing pipeline is much more difficult to clean, the dead angle is difficult to clean, and the probability of styles is high, affecting the processing effect of the wine mother. Inventive content [0003] In response to the above technical problems, the present invention provides an alcohol-to-liquor-divided feed line, including: [0004] No. 1 alcohol, No. 2 alcohol, fee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12M1/00C12M1/04A61L2/07

CPCA61L2/07C12M23/58C12M29/06

Inventor 陈乾

Owner 江苏罗迈特生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com