Anchoring structure and construction method of soil nailing wall supporting structure

An anchoring structure and anchor pipe technology, which is used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of the need to improve the connection strength of soil nails and soil, and the small contact area between the cement slurry and the inner wall of the borehole. Reduce the difficulty of extrusion, improve the effect, and improve the effect of the straightness of the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

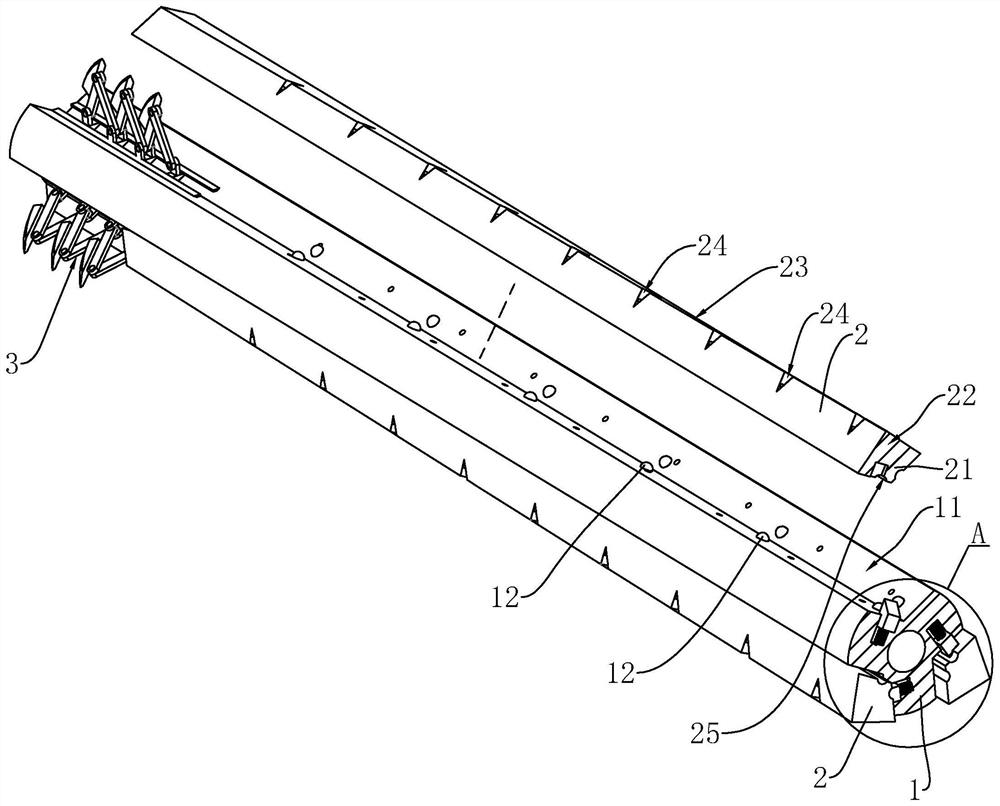

[0043] The following is attached Figure 1-6 The application is described in further detail.

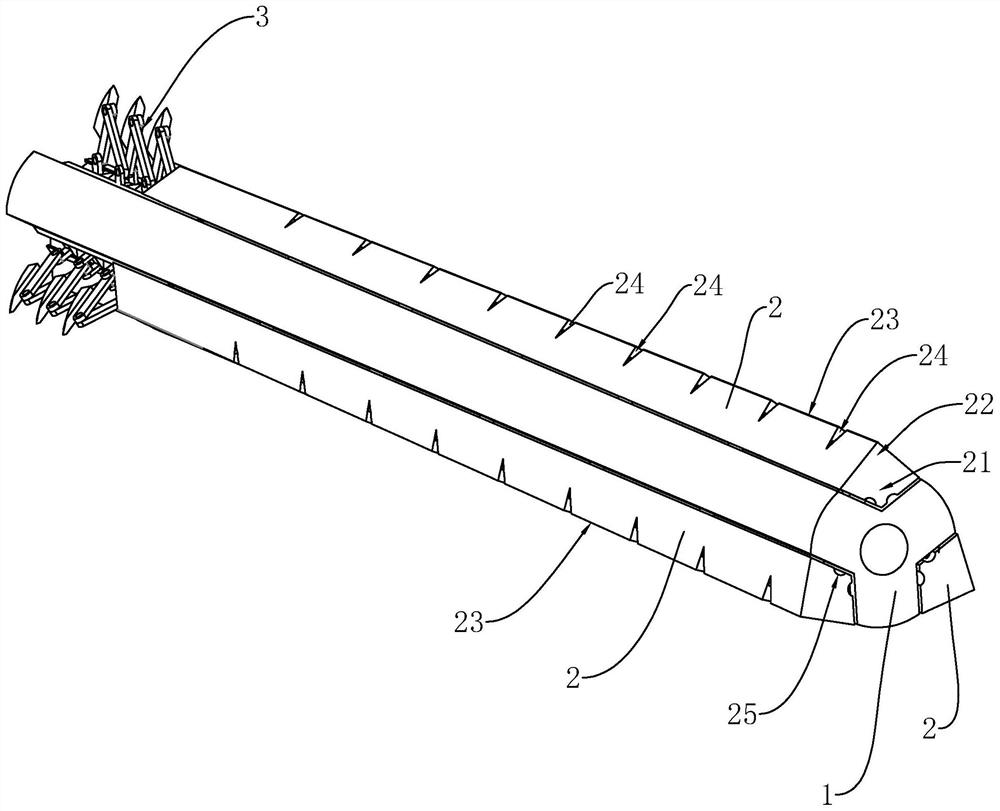

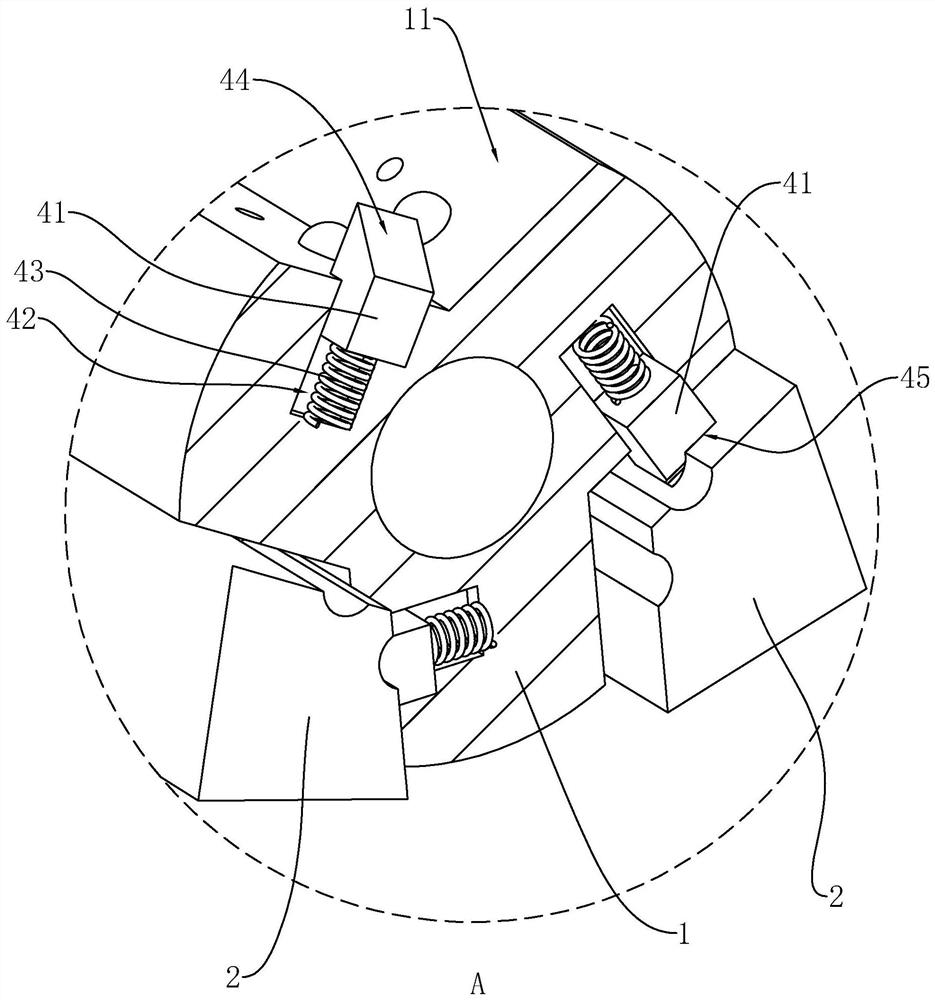

[0044] The embodiment of the present application discloses an anchoring structure, referring to figure 1 , figure 2 , the anchoring structure includes an anchor tube 1, three extruded strips 2 arranged outside the anchor tube 1, and a limiting assembly for connecting the anchor tube 1 and the extruded strip 2; one end of the anchor tube 1 is a grouting port, and the other end Closed, the outer peripheral wall of the anchor pipe 1 is provided with three concave grooves 11 uniformly distributed on the circumference, the concave grooves 11 are arranged along the axial direction of the anchor pipe 1, and the angle between the two groove walls of the concave groove 11 is equal to 120 degrees; The bead 2 is slidingly connected with the concave groove 11 along the axial direction of the anchor pipe 1 .

[0045] During construction, first put the anchor pipe 1 into the anchor hole, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com