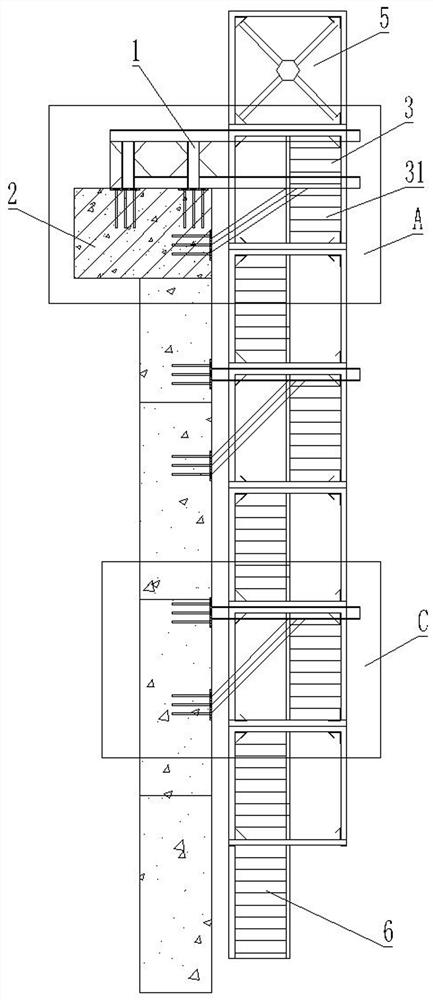

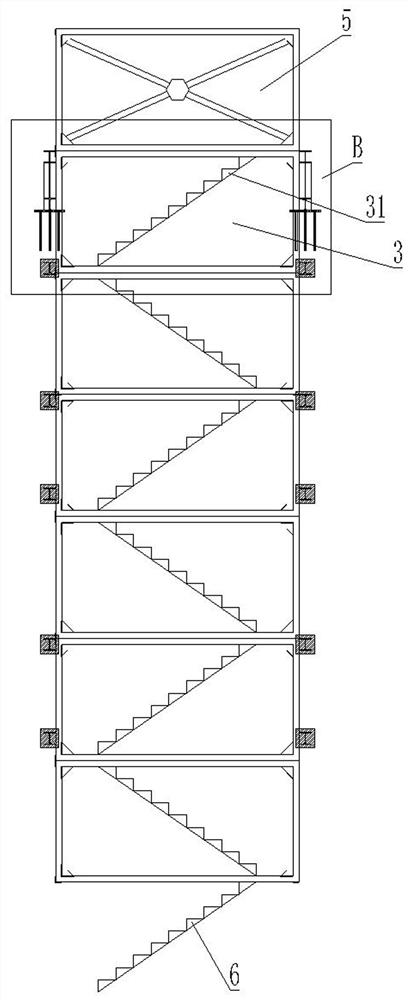

Upper and lower well channel for constructing ultra-deep vertical shaft by reverse construction method and construction method thereof

A reverse method, shaft technology, applied in shaft equipment, buildings, artificial islands, etc., can solve the problem of inconvenient people going up and down in ultra-deep working shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

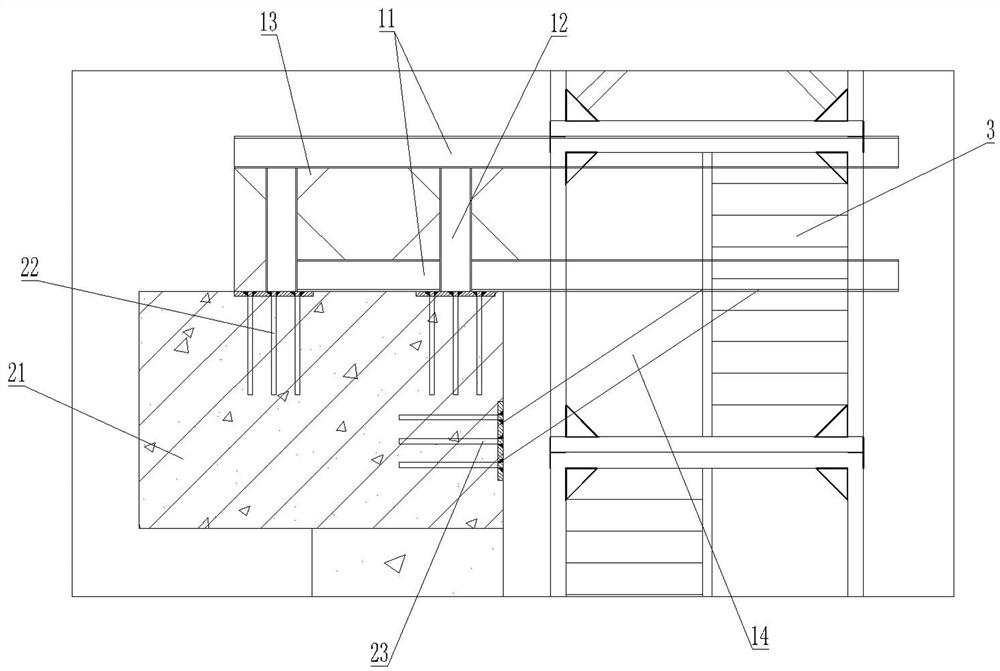

[0049] A method for constructing the upper and lower shaft passages of the ultra-deep shaft constructed by the reverse method, which is used to construct the upper and lower shaft passages of the ultra-deep shaft constructed by the reverse method in Example 1, specifically comprising the following steps:

[0050] (1) During the construction process of the ultra-deep shaft using the reverse method, when constructing the reinforcement cage of the top beam of the ultra-deep shaft, the first connector is installed on the reinforcement cage of the top beam, and the first connector is welded to the reinforcement of the top beam After that, the concrete for the top beam is poured and the first connector is pre-embedded in the top beam. When the top beam is completely solidified, the second half of the suspension beam frame is placed on the top beam and fixedly connected with the first connection piece. The suspension beam frame The front half is suspended, and the top box-type ladder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com