Multifunctional valve

A multi-functional, valve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problem of single function, and achieve the effects of avoiding pipe bursting, reasonable structural design, and preventing thermal expansion and cold contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

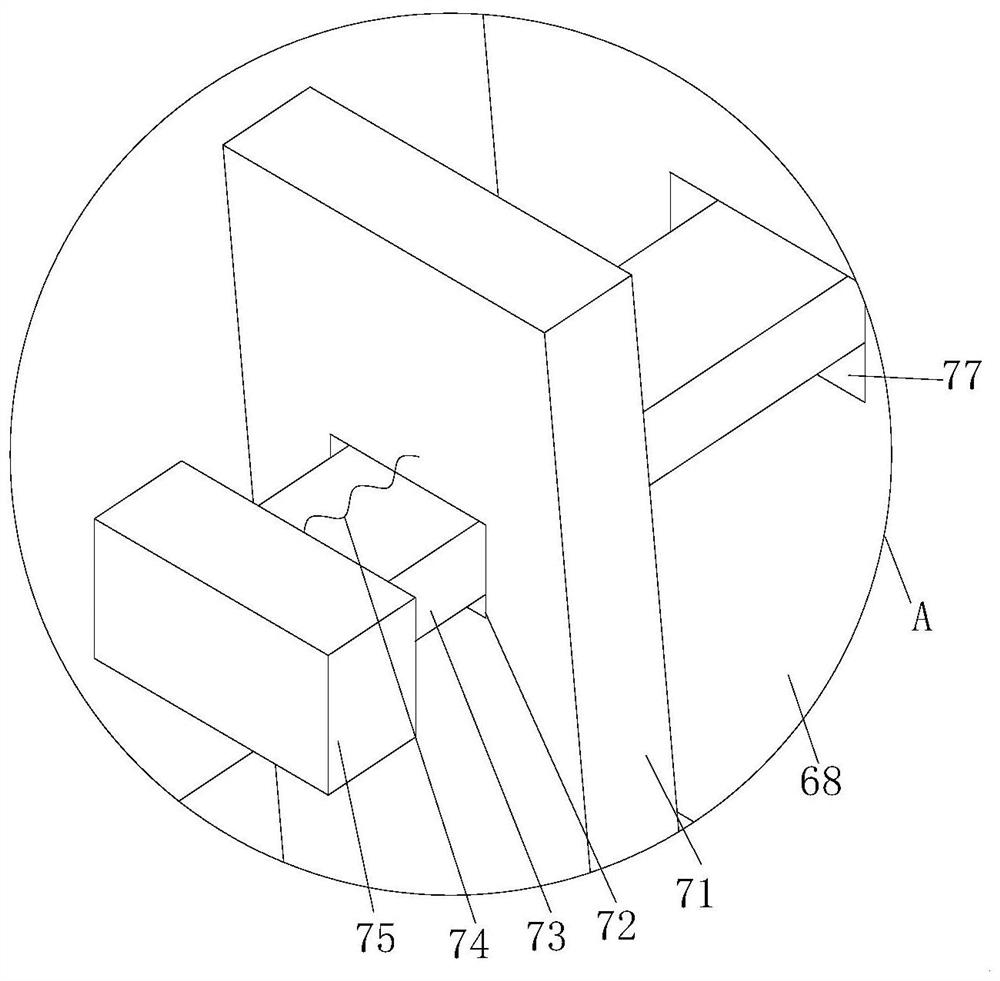

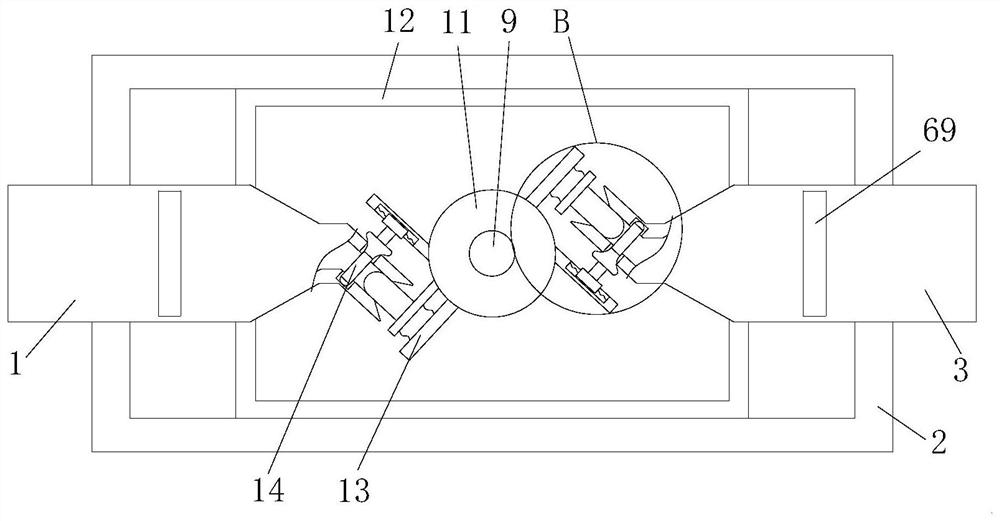

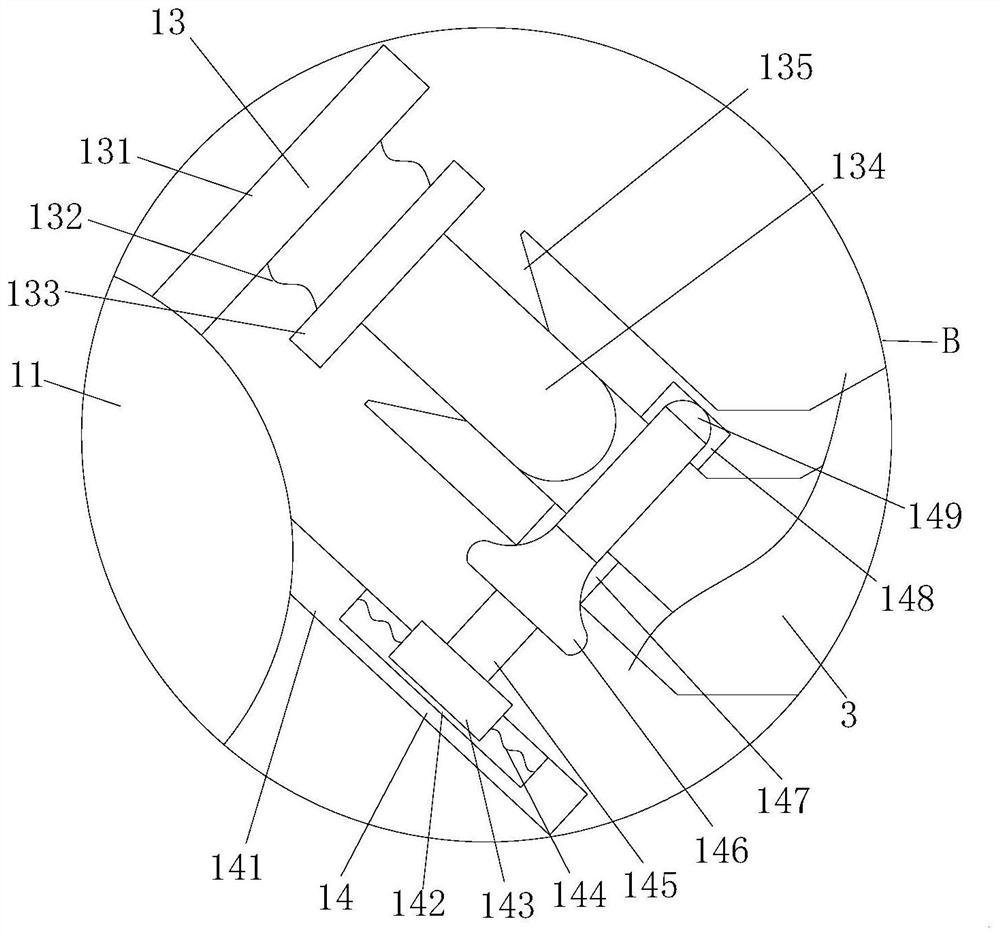

[0032] Attached below Figure 1-4 The present invention is further described with embodiment:

[0033] A multi-functional valve, comprising a water inlet pipe 1, a regulating box 2 and a water outlet pipe 3, the water inlet pipe 1 and the water outlet pipe 3 are respectively fixed and plugged on the two ends of the regulating box 2, the water inlet pipe 1, the regulating box 2 and the water outlet pipe 3 Both are made of memory alloy material, and one end of the water inlet pipe 1 and the water outlet pipe 3 located in the regulating box 2 extends into the sealing box 12, and the sealing box 12 is fixedly arranged in the regulating box 2, and the top plate of the regulating box 2 is provided with limited threaded holes 10, and the limit threaded hole 10 is internally threaded with the limit threaded rod 9, the upper end of the limit threaded rod 9 is connected with a twisting disc 8, and the limit threaded rod 9 moves through the top plate of the sealing box 12, and is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com