Intelligent afterheat recycling device for urban waste incineration

A waste heat recovery device and municipal waste technology, applied in heat exchangers, incinerators, combustion methods, etc., can solve the problems of small utilization range, small heat, heat loss, etc., to avoid heat loss and large heat supply , the effect of accelerating delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

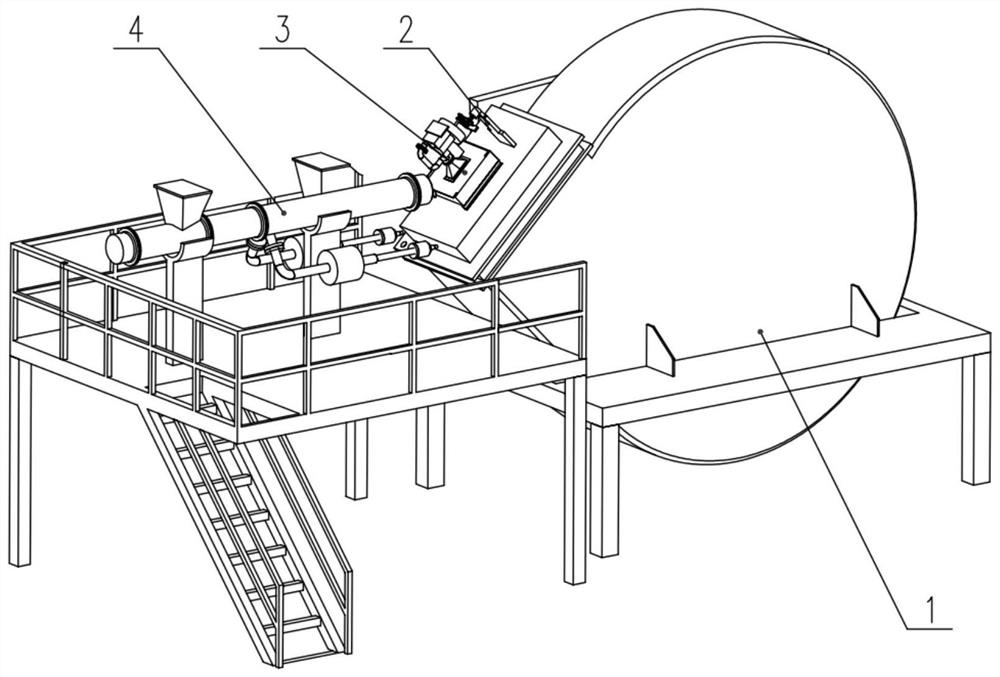

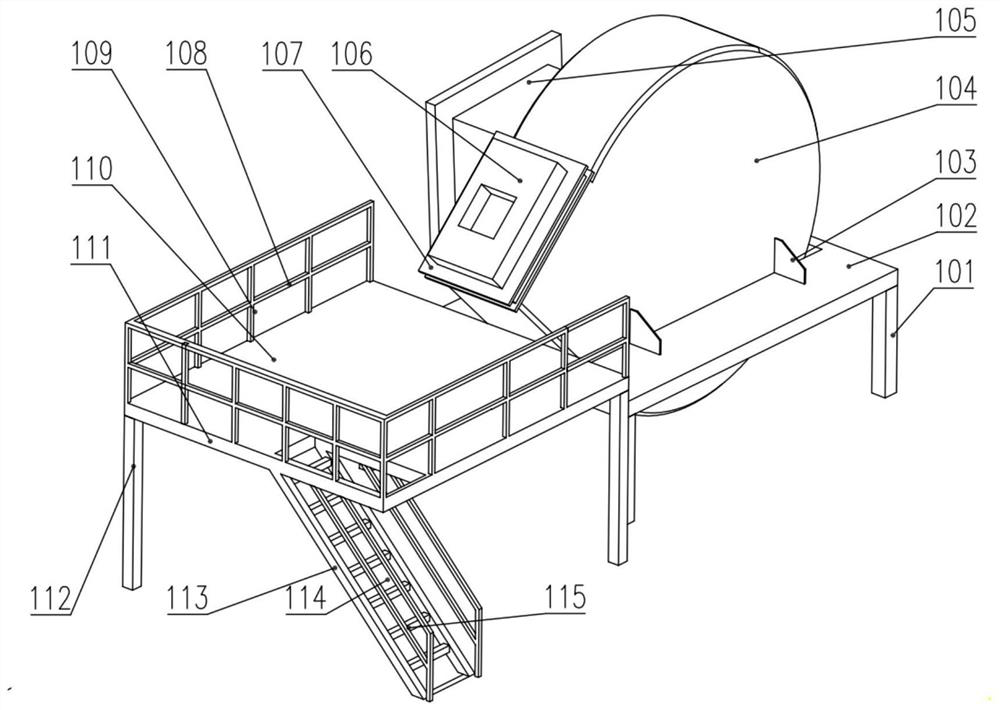

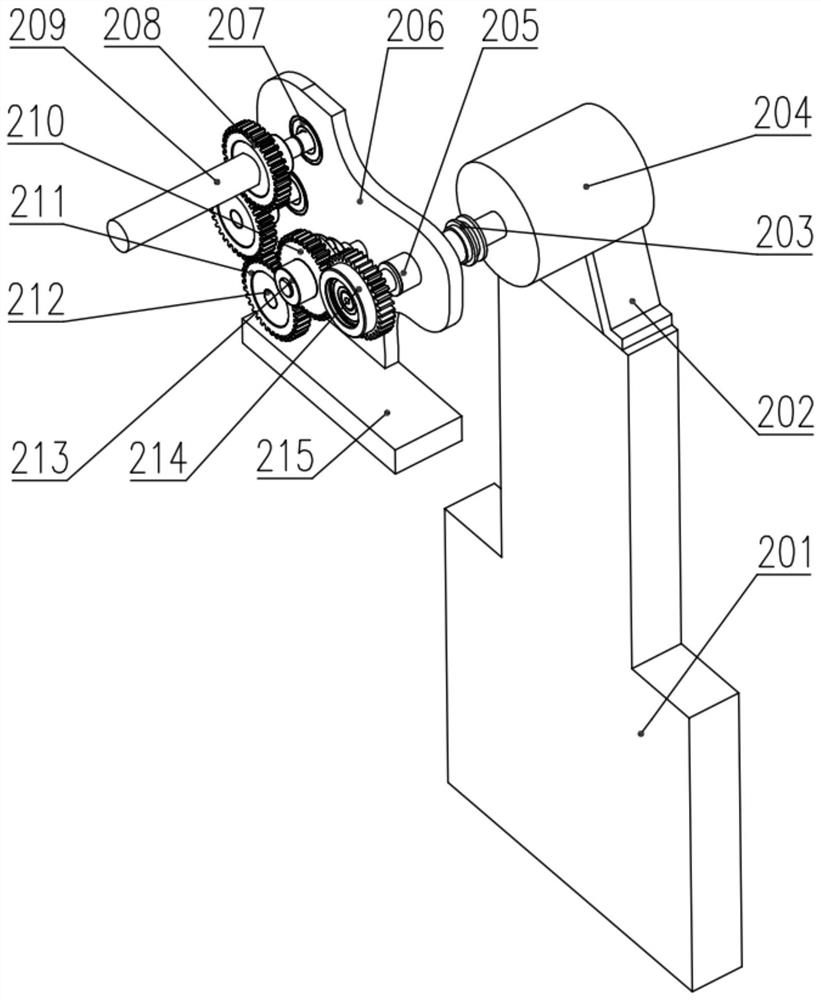

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The waste heat recovery device for waste incineration in a smart city includes a recovery integration 1 , a transmission system 2 , a heat sending device 3 , and a heat collection system 4 .

[0024] The specific structure of a smart city waste incineration waste heat recovery device is as follows: figure 1 As shown, the recovery unit 1 is fixedly installed on the ground, the transmission system 2 is fixedly installed on the recovery unit 1, the heat sending device 3 is fixedly installed on the recovery unit 1, and the heat collection system 4 is fixedly installed on the recovery unit 1. This kind of smart city waste incineration waste heat recovery device is fixedly installed at the heat exhaust outlet of the waste incineration station, wherein the recovery integration 1 is the main supporting body, and the transmission system 2, heat sending device 3 and heat collection system 4 are fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com