Pressure type high-temperature thermochemical heat storage tank system and working method thereof

A pressure type, heat storage tank technology, applied in the field of energy storage systems, can solve problems such as huge, no mature application systems, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

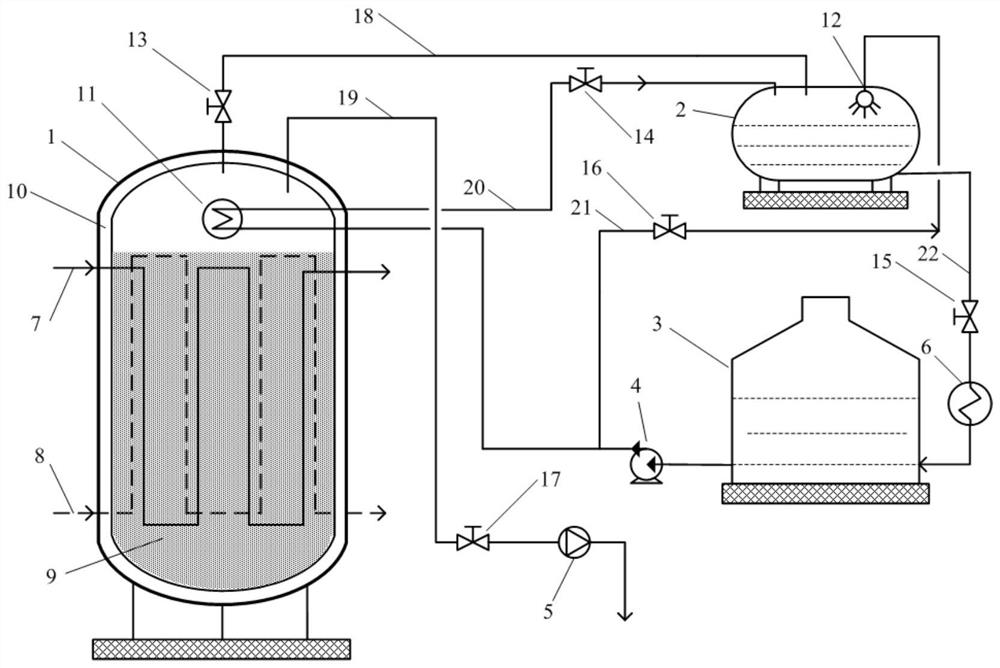

[0022] refer to figure 1 , a pressure-type high-temperature thermochemical heat storage tank system of the present invention consists of a reaction storage tank 1, a surge tank 2, a water storage tank 3, a booster pump 4, a vacuum pump 5, a cooler 6, a reaction steam pipeline 18, and a vacuum tube Road 19, steam generation pipeline 20, cooling spray pipeline 21, drain pipeline 22 and the corresponding valves of each pipeline; wherein, reaction storage tank 1 is composed of vacuum insulation layer 10, reaction material 9, steam generator 11, The primary heat exchanger pipeline 7 and the secondary heat exchanger pipeline 8 are composed of a cooling shower 12 in the surge tank 2; the reaction storage tank 1 is filled with a reaction material 9 such as Ca(OH) 2 Or CaO powder, whose reaction equation is Ca(OH) 2 CaO+H 2 O, can also realize a variety of other similar gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com