Phase change heat storage device

A technology of phase change heat storage and phase change materials, applied in heat storage equipment, heat transfer modification, heat exchange equipment, etc., can solve the problems of low heat storage efficiency and slow heat storage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Carry out further explanation below in conjunction with accompanying drawing:

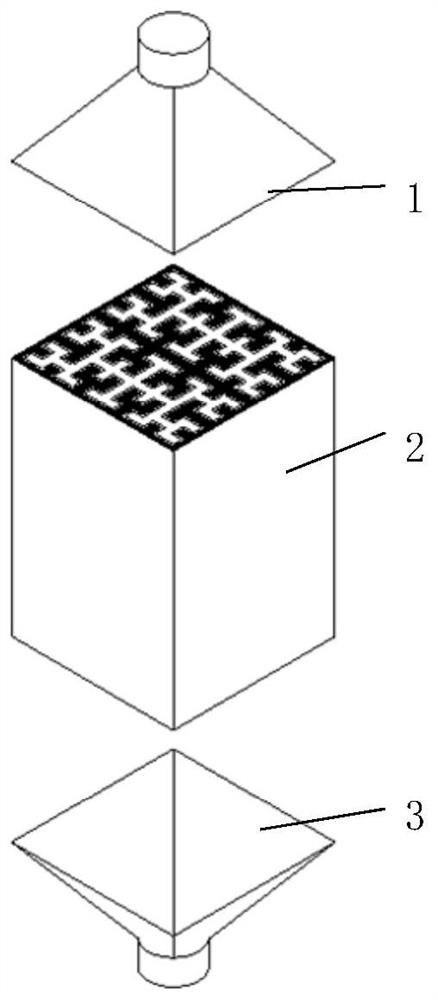

[0024] figure 1 Shown is a schematic diagram of the three-dimensional structure of the phase change heat storage device of the present invention. The phase change heat storage device includes an energy storage unit, a disturbing body 6 and a fluid transport channel.

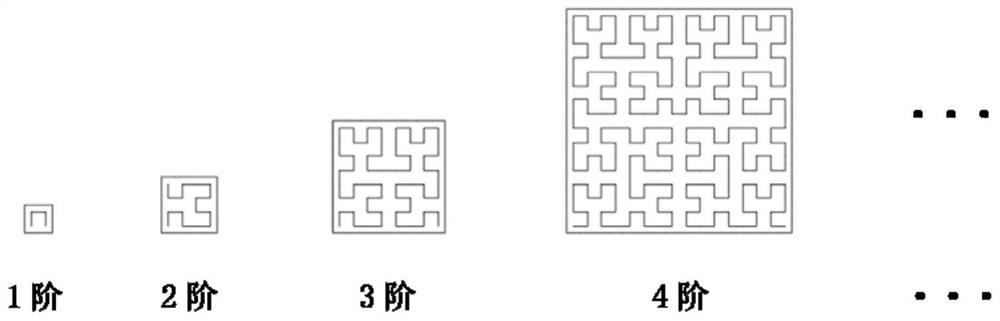

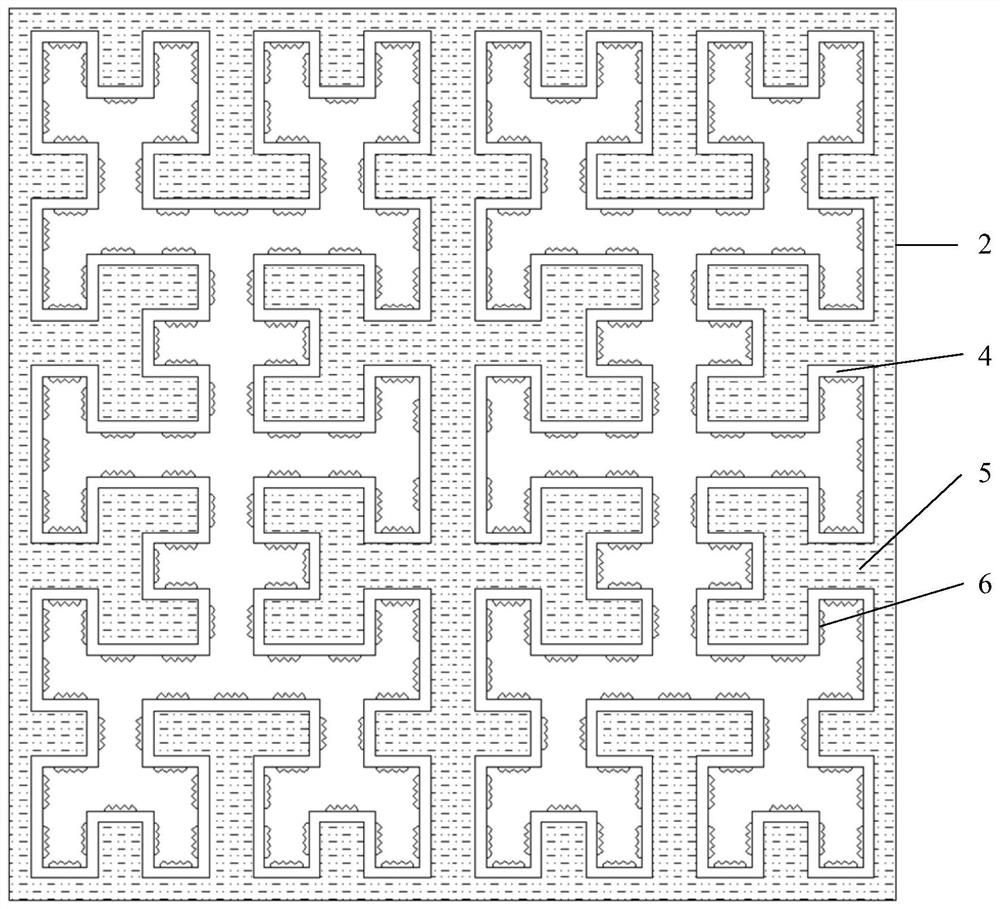

[0025] The energy storage unit is composed of thermal insulation material, shell 2, Hilbert curve configuration metal skeleton 4 and phase change material 5: the thermal insulation material is wrapped on the outside of the shell 2, which has high thermal resistance and can effectively prevent heat loss; The Hilbert curve configuration metal skeleton 4 is evenly distributed inside the shell 2, which not only increases the heat exchange surface between the fluid and the phase change material 5, but also makes the temperature distribution inside the shell 2 more uniform and the heat transfer is faster; the phase change The mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com