Switch cabinet bus detection tool

A technology for detecting tooling and switchgear, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems that the busbar of switchgear is not easy to detect, etc., and achieve the goals of shortening the processing cycle, good versatility, and speeding up the delivery time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

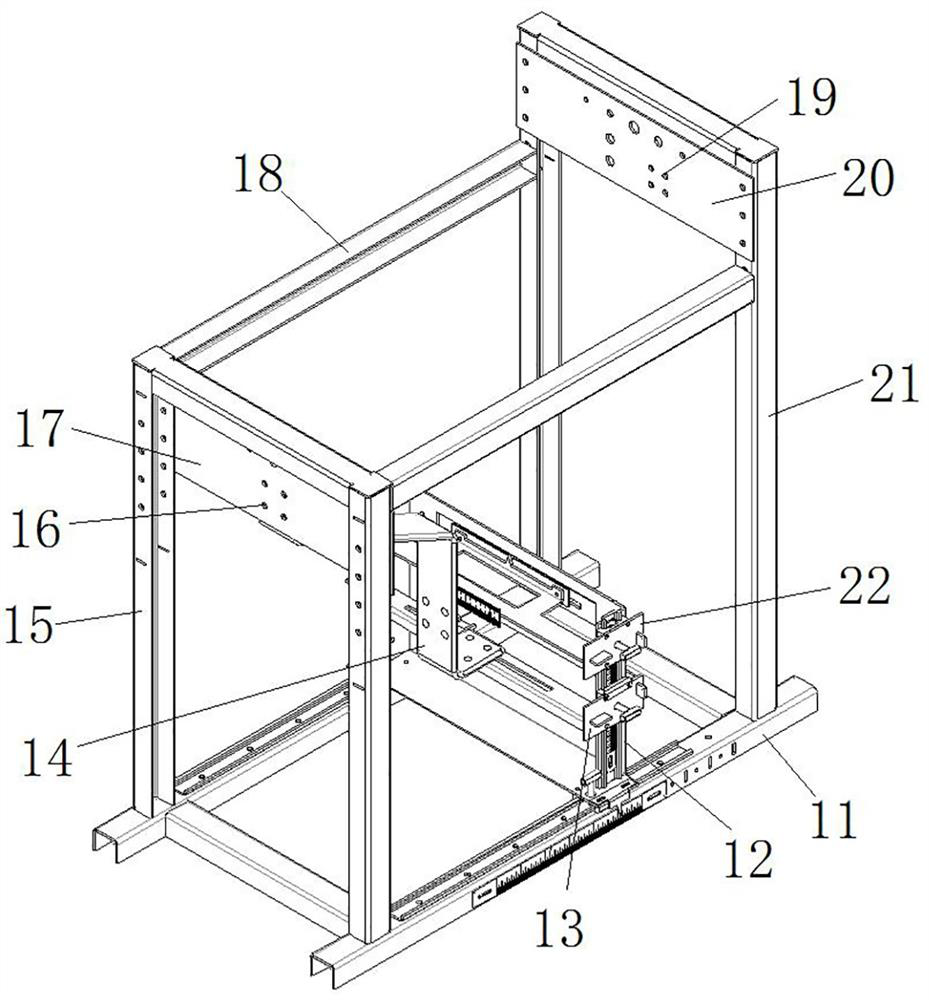

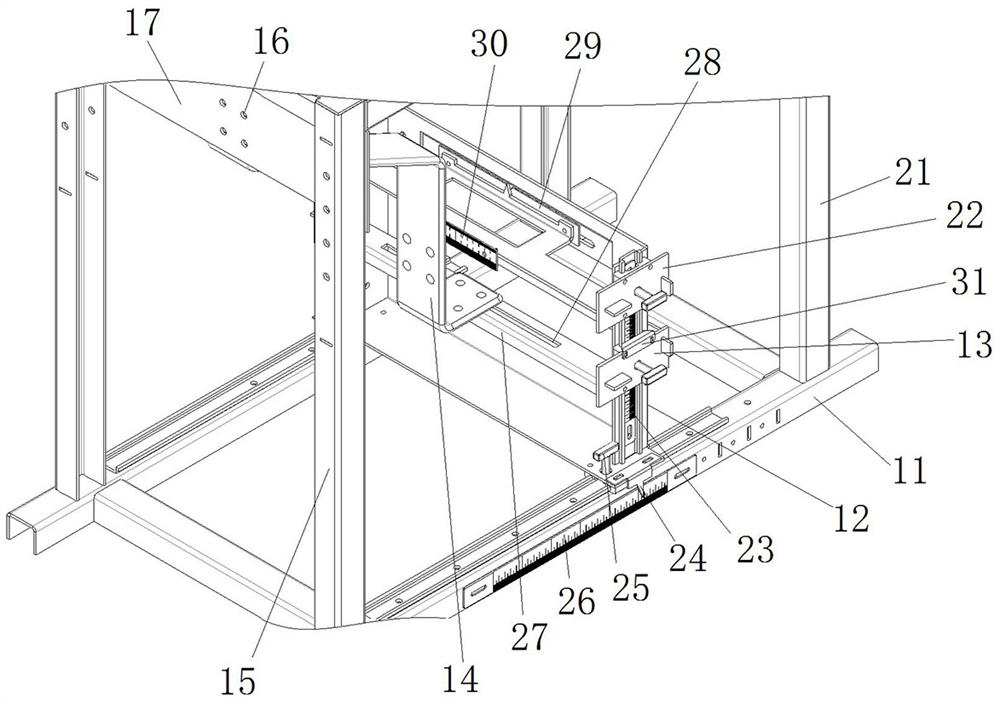

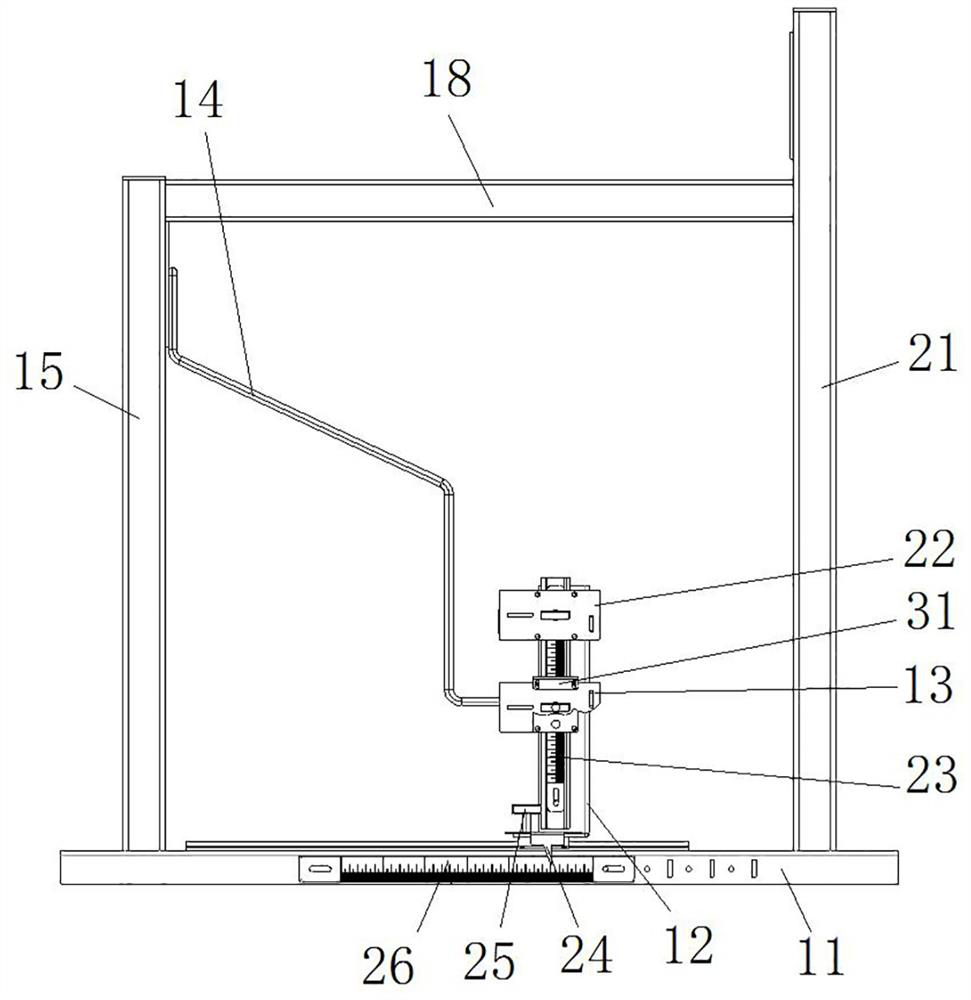

[0043] Such as figure 1 with figure 2 As shown, the switchgear bus detection tooling includes an underframe 11, the left and right ends of the underframe 11 are respectively provided with a first stand 15 and a second stand 21, between the first stand 15 and the second stand 21 The cross brace 18 is used to ensure the stability of the first stand 15 and the second stand 21 .

[0044]In this embodiment, the first stand 15 is fixed with a first fixing plate 17 by bolts, the first fixing plate 17 is provided with a first busbar fixing hole 16, and a plurality of first busbar fixing holes 16 are provided, and the first busbar The fixing hole 16 is used to fix one end of the busbar 14 of the switch cabinet; the number of the first busbar fixing holes 16 is multiple, and one or more than two first busbar fixing holes 16 form the first busbar fixing position, so that the first fixing plate 17 There are at least two first busbar fixing positions on the top, so that the tooling can ...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the bus bar installation frame 13 is provided with a fixed long hole 28, and the fixed long hole 28 extends along the front and rear direction, and the fixed long hole 28 is used to fix the switch cabinet bus 14 the other end of the Wherein, the long fixing holes 28 form a plurality of second busbar fixing positions on the busbar installation frame 13 . In this embodiment, the busbar installation frame is provided with a plurality of fixed round holes, the fixed round holes are used to fix the other end of the switch cabinet busbar, and one or more than two fixed round holes form the second busbar fixing position, so that the busbar can be installed At least two second bus bar fixing positions are arranged on the frame.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the left and right ends of the underframe 11 are respectively provided with a first stand 15 and a second stand 21, and the first stand 15 is fixed with bolts. The first fixed plate 17, the second stand 21 is fixed with the second fixed plate 20 by bolts, the position of the second fixed plate 20 is higher than the position of the first fixed plate 17, so that the frock can adapt to more different sizes Switchgear busbar 14. However, in this embodiment, when there are fewer types of switchgear busbars, only the first stand or the second stand is set on the bottom frame. At this time, the horizontal mounting plate and the first vertical mounting plate are arranged on the sliding frame on the same side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com