Failure analysis method for fiber-reinforced flexible composite oil pipe

A composite tubing and fiber-reinforced technology, which is applied in the analysis of materials, strength characteristics, and material thermal analysis, can solve problems such as unsystematic and blind failure analysis of non-metallic composite tubing, and achieve easy implementation, easy reference and use, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

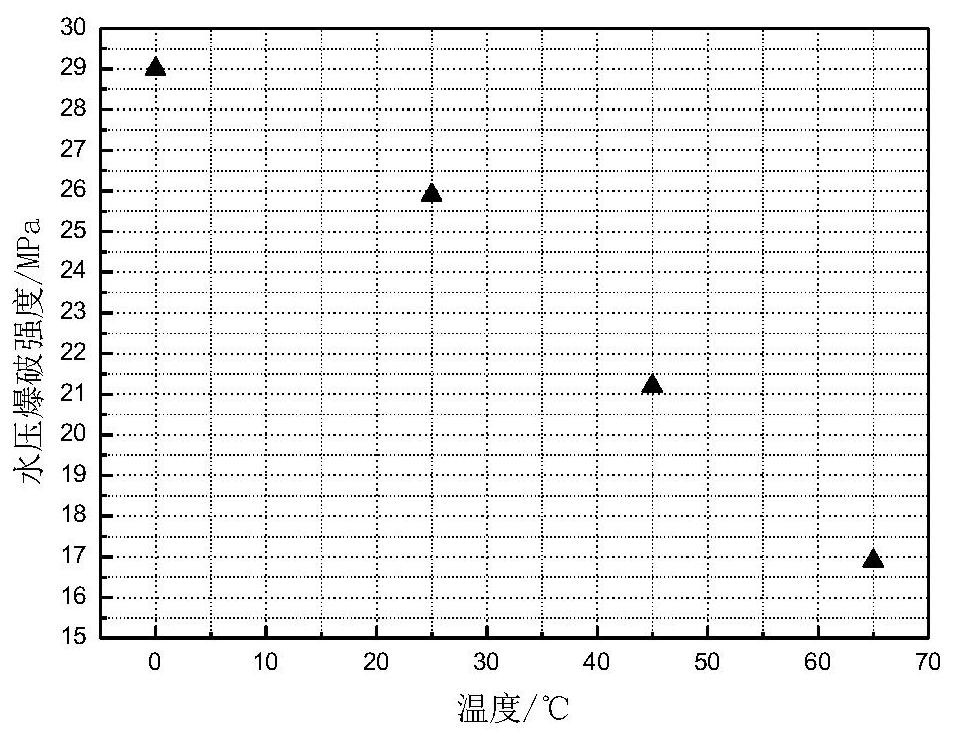

[0039] Example 1: Determining the cause of failure of polyester fiber reinforced flexible composite tubing in service in a high temperature environment (45°C) in an oilfield

[0040] (1) Select the pipe material and preparation work required for the test. Randomly select 4 pipes from the same batch as the field service, and 1 pipe is a group, numbered 1#, 2#, 3#, 4# respectively. (2) Carry out the test of simulated temperature. Select 0°C, 25°C, 45°C and 65°C temperature points for insulation. The distribution of temperature points includes extreme temperature points of 0°C, 65°C and service temperature of 45°C. (3) Short-term hydraulic failure test. According to the standard GB / T 15560-1995, the blasting test is carried out on the pipes 1#, 2#, 3# and 4# of the prefabricated failure mode, and the short-term hydraulic failure strength is tested, and the value is obtained, 1#, 2#, 3# , 4# composite pipe short-term hydraulic failure strength values are 29MPa, 26MPa, 21MPa ...

example 2

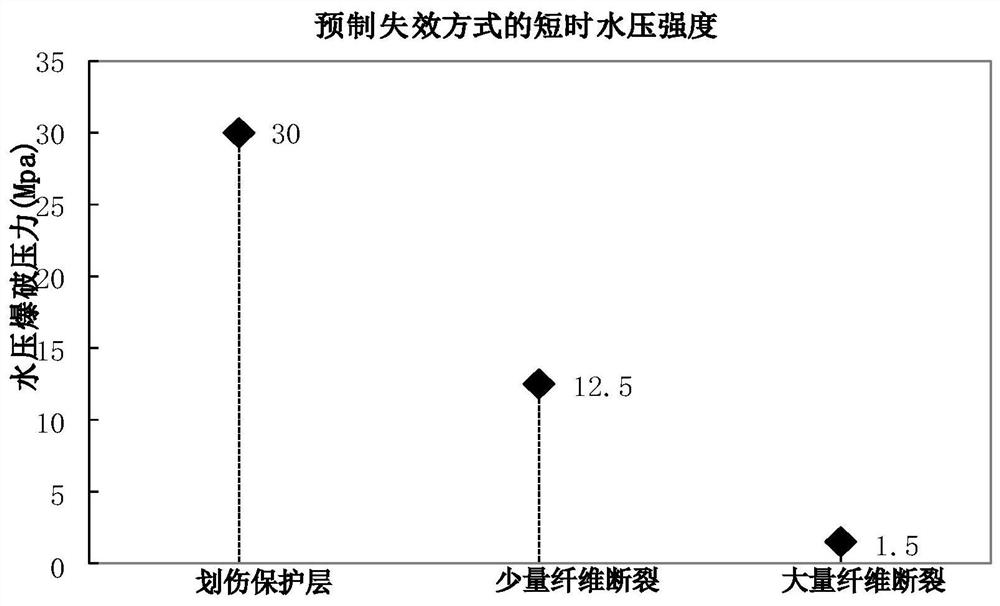

[0041] Example 2: Judgment of the cause of failure of aramid fiber reinforced flexible composite tubing in service in a high temperature environment (45°C) in an oilfield

[0042] (1) Select the pipe material and preparation work required for the test. Randomly select 4 pipes from the same batch as the field service, and 1 pipe is a group, numbered 1#, 2#, 3#, 4# respectively. (2) Carry out the test of simulated temperature. Select 0°C, 25°C, 45°C and 65°C temperature points for insulation. The distribution of temperature points includes extreme temperature points of 0°C, 65°C and service temperature of 45°C. (3) Short-term hydraulic failure test. According to the standard GB / T 15560-1995, the blasting test is carried out on the pipes 1#, 2#, 3# and 4# of the prefabricated failure mode, and the short-term hydraulic failure strength is tested, and the value is obtained, 1#, 2#, 3# , 4# composite pipe short-term hydraulic failure strength values are 26MPa, 30MPa, 29MPa and...

example 3

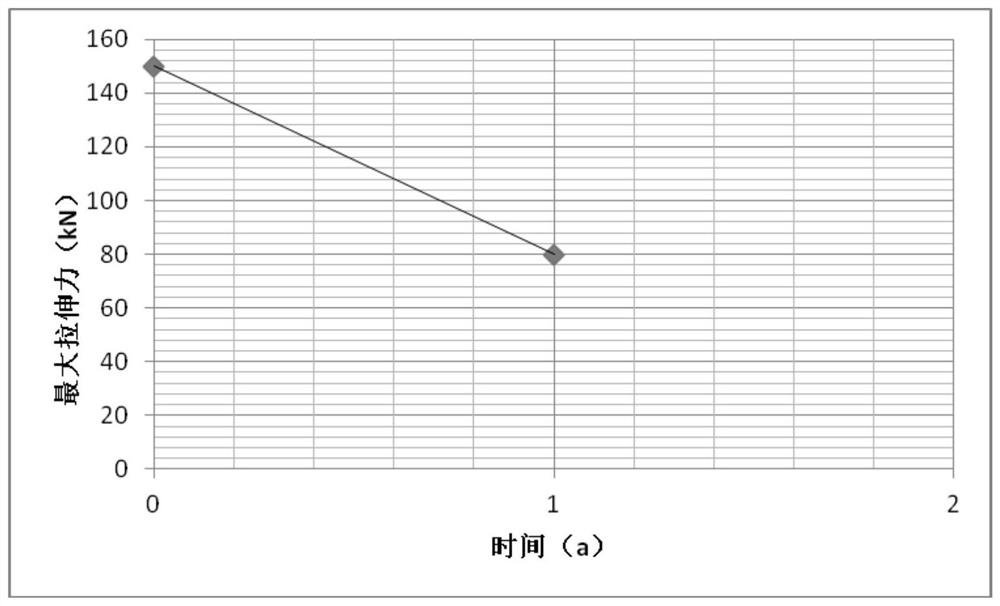

[0043] Example 3: Judging the cause of failure of aramid fiber reinforced flexible composite tubing in an oilfield in high temperature environment (45°C) for one year

[0044] (1) Select the pipe material and preparation work required for the test. Randomly select 4 pipes from the same batch as the field service, and 1 pipe is a group, numbered 1#, 2#, 3#, 4# respectively. (2) Carry out the test of simulated temperature. Select 0°C, 25°C, 45°C and 65°C temperature points for insulation. The distribution of temperature points includes extreme temperature points of 0°C, 65°C and service temperature of 45°C. (3) Short-term hydraulic failure test. According to the standard GB / T 15560-1995, the blasting test is carried out on the pipes 1#, 2#, 3# and 4# of the prefabricated failure mode, and the short-term hydraulic failure strength is tested, and the value is obtained, 1#, 2#, 3# , 4# composite pipe short-term hydraulic failure strength values are 26MPa, 30MPa, 29MPa and 29M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com