Method for measuring residual magnetism in shielding barrel based on in-situ magnetometer

A measurement method and magnetometer technology, applied in the field of atomic sensors, can solve problems such as complex operation and inability to reflect the shielding effect of shielding barrels on environmental residual magnetism, and achieve the effect of simple and convenient measurement operation, convenient design and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

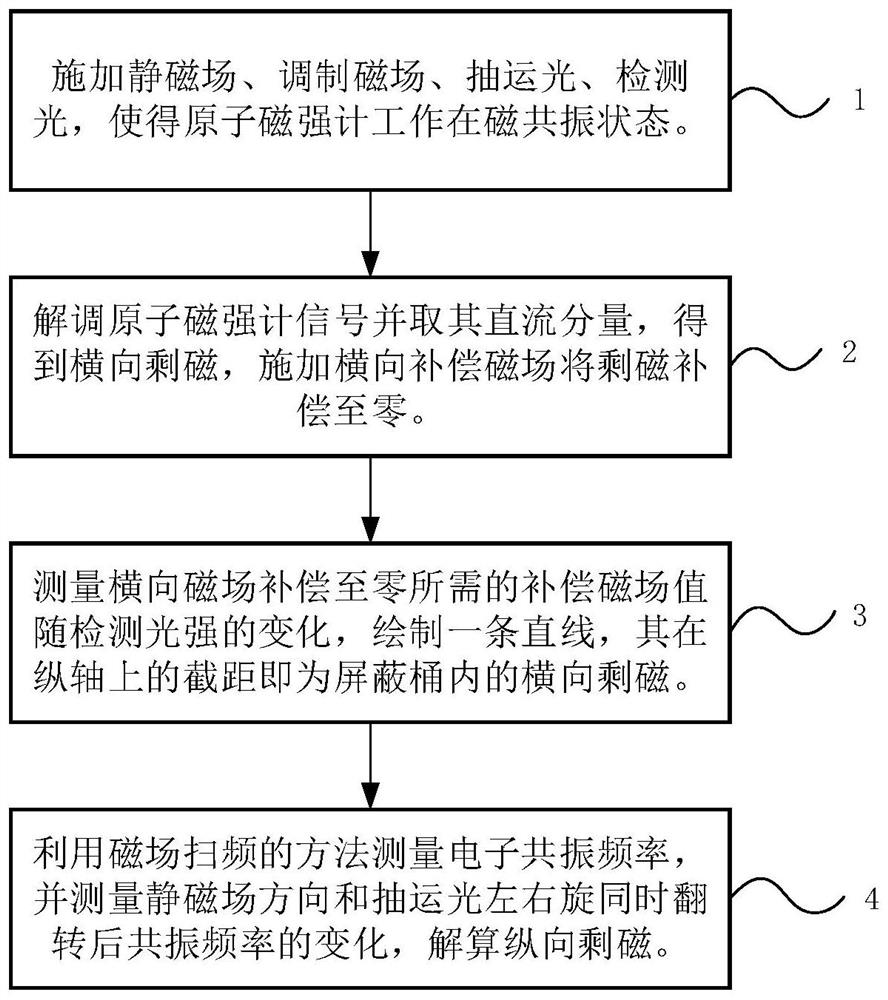

[0017] Concrete implementation steps of the present invention are as figure 1 As shown, a total of 4 steps are included, and the specific steps are as follows:

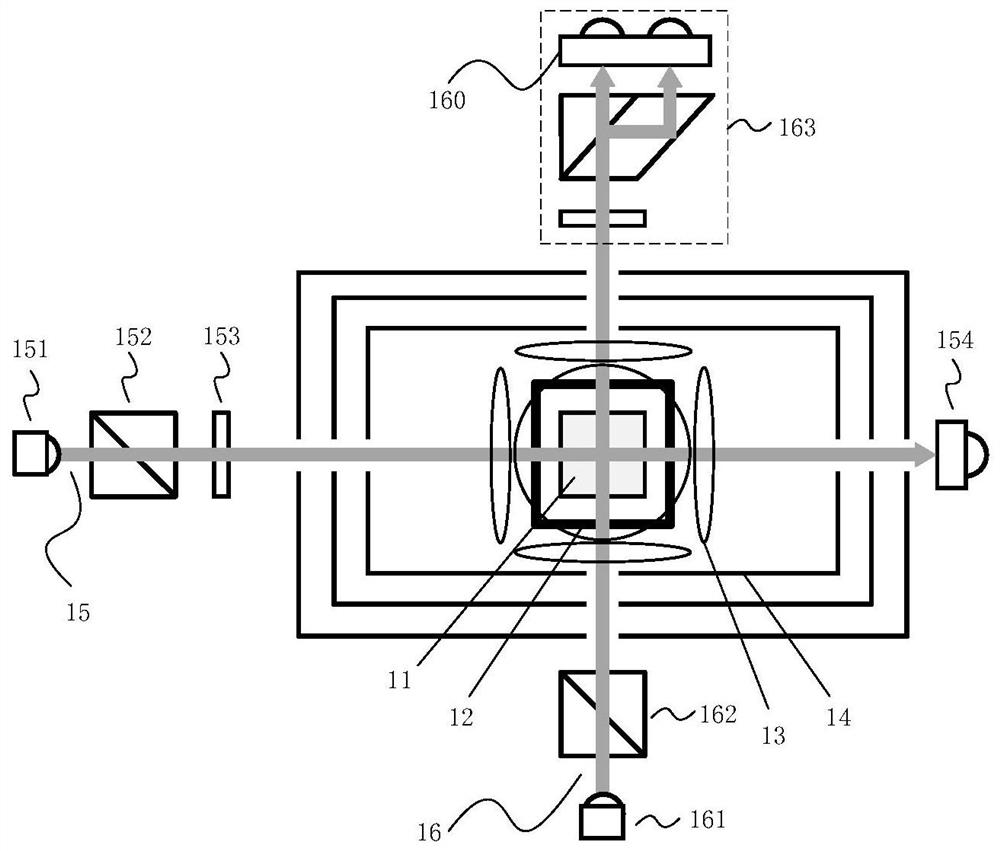

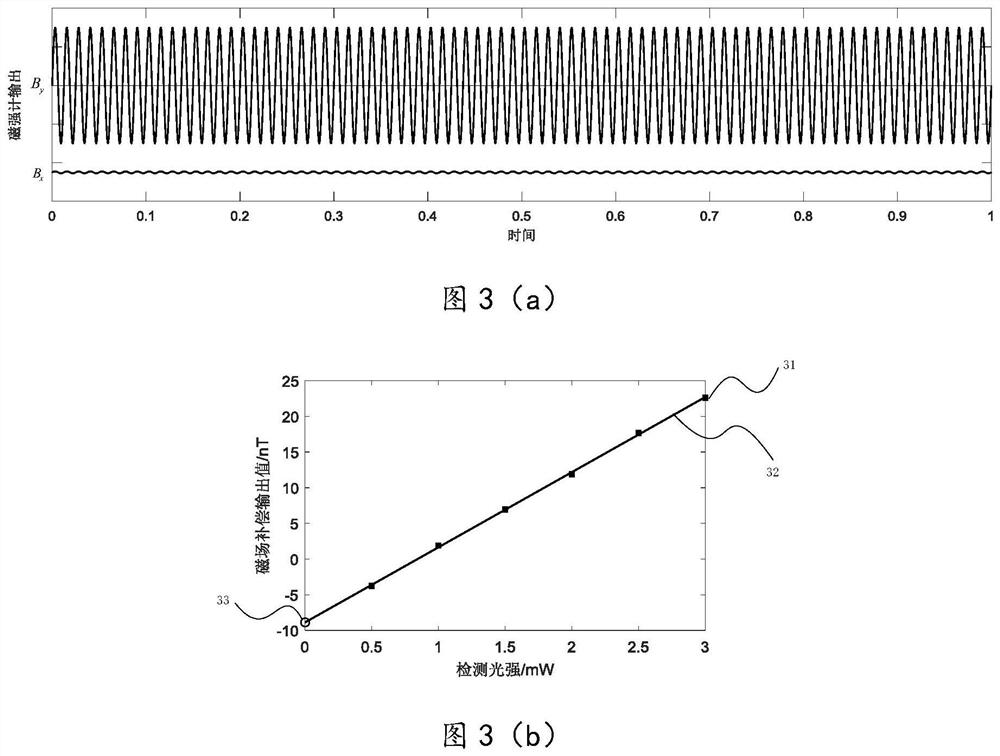

[0018] Step 1. Build an atomic sensor system, including an atomic gas chamber, an oven, a three-axis coil, a multi-layer magnetic shielding barrel, a pumping optical path, and a detection optical path. Then apply a static magnetic field in the longitudinal direction, that is, the direction of the pumping light, and apply circularly polarized pumping light to polarize the atoms, and the atoms will precess around the static magnetic field. Then apply a modulated magnetic field with the same frequency as the atomic precession in the longitudinal direction to make the atomic magnetometer work in a resonance state, and use a beam of linearly polarized detection light to detect the atomic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com