Fermentation process stage division method based on dynamic feature extraction

A technology of dynamic characteristics and fermentation process, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of inaccurate division of fermentation process stages and division of production process into multiple sub-stages, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

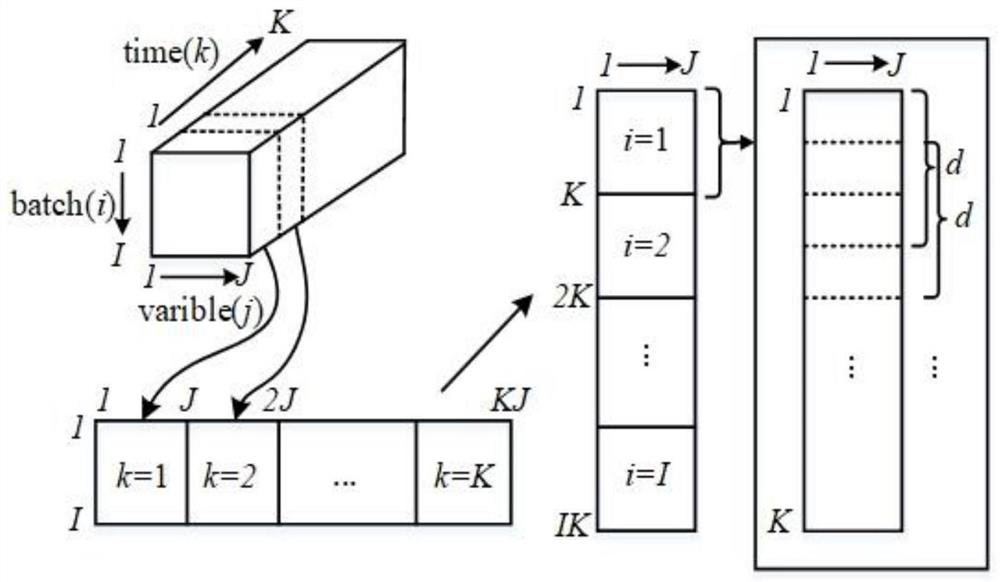

[0036] The Pensim simulation platform is an internationally influential penicillin simulation platform, and relevant research has shown its practicability and effectiveness. In this paper, based on this platform, the experimental simulation of the fermentation process of penicillin was carried out. The fermentation time of each batch was set to 400h, the sampling interval was 1h, and 11 process variables were selected (including ventilation rate, stirring power, substrate flow acceleration rate, substrate Temperature, dissolved oxygen concentration, exhaust carbon dioxide concentration, pH, temperature, reaction heat, cold water flow acceleration rate and substrate concentration) and 1 quality variable (product concentration) were monitored, and 40 batches of penicillin fermentation processes were selected for training in this paper Modeling, 20 batches for prediction.

[0037] Table 1 Penicillin Fermentation Process Variables

[0038] Table 1 Process variables of Penicillin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com