Voltage regulation equipment load state evaluation method and equipment and readable storage medium

A technology of load status and equipment, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as hidden safety hazards, the impact of gas consumption, and overloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

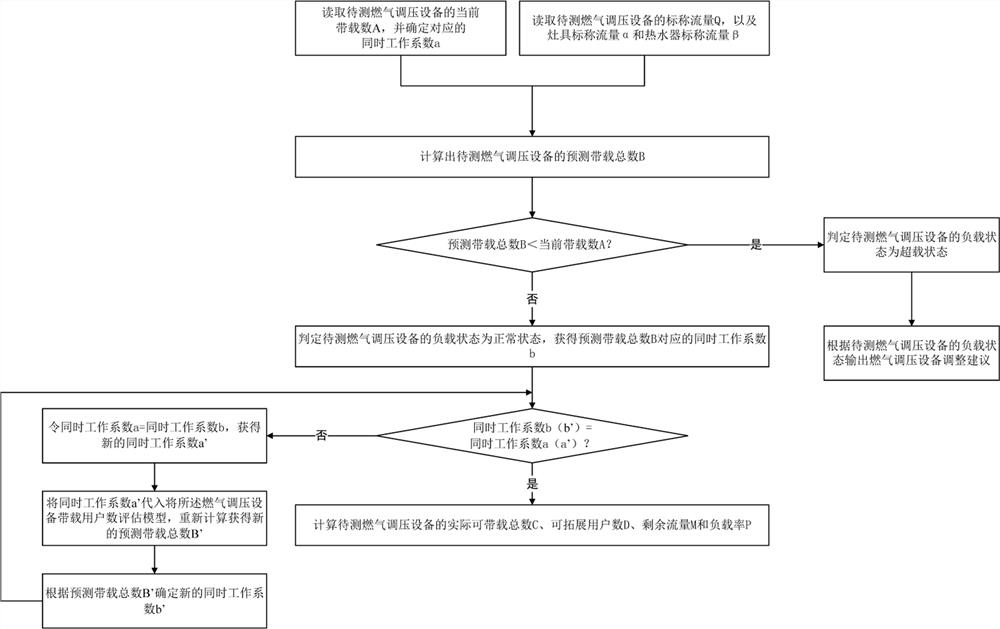

[0026] attached figure 1 A flow chart of a load state evaluation method for gas pressure regulating equipment is shown.

[0027] The method for evaluating the load state of the gas pressure regulating equipment includes the following steps: obtaining the current load A of the gas pressure regulating equipment to be tested and determining the corresponding simultaneous operation coefficient a, reading the nominal flow rate Q, Nominal flow α of cooker and nominal flow β of water heater;

[0028] Configure the load floating coefficient c of the gas pressure regulating equipment to be tested, and construct the gas regulating equipment based on the nominal flow Q of the gas pressure regulating equipment to be tested, the nominal flow α of the cooker, the nominal flow β of the water heater, the simultaneous work coefficient a and the load floating coefficient c Evaluation model for the number of loaded users of pressure equipment;

[0029] According to the evaluation model of the ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the corresponding simultaneous operation coefficient b is determined according to the predicted load total number B of the gas pressure regulating equipment to be tested,

[0040] After judging that the load state of the gas pressure regulating equipment to be tested is normal, it is also executed:

[0041] judging whether the simultaneous operation coefficient b is equal to the simultaneous operation coefficient a,

[0042] If the simultaneous operation coefficient b is not equal to the simultaneous operation coefficient a, then assign the simultaneous operation coefficient b to the simultaneous operation coefficient a to obtain a new simultaneous operation coefficient a', and recalculate to obtain a new simultaneous operation coefficient b', until the calculated simultaneous operation coefficient b' is equal to the simultaneous operation coefficient a';

[0043]If the simultaneous operation coefficient b...

Embodiment 3

[0056] This embodiment provides a load state evaluation device for a gas pressure regulating device. The load state evaluation device for a gas pressure regulating device includes a memory, a processor, and a gas stored in the memory and operable on the processor. A load state evaluation program for pressure regulating equipment, when the load state evaluation program for gas pressure regulating equipment is executed by the processor, the steps of the method for evaluating the load state of gas pressure regulating equipment in the above-mentioned embodiments are implemented.

[0057] This embodiment also provides a readable storage medium on which instructions are stored, and when the instructions are executed by a processor, the steps of the above-mentioned method for evaluating the load state of a gas pressure regulating device are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com