A pixel driving circuit, active electroluminescence display and driving method

A pixel driving circuit and electroluminescence technology, applied in static indicators, instruments, etc., can solve the problems of limited grayscale, MicroLED color shift, wrong contour, etc., and achieve the effect of large PWM pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

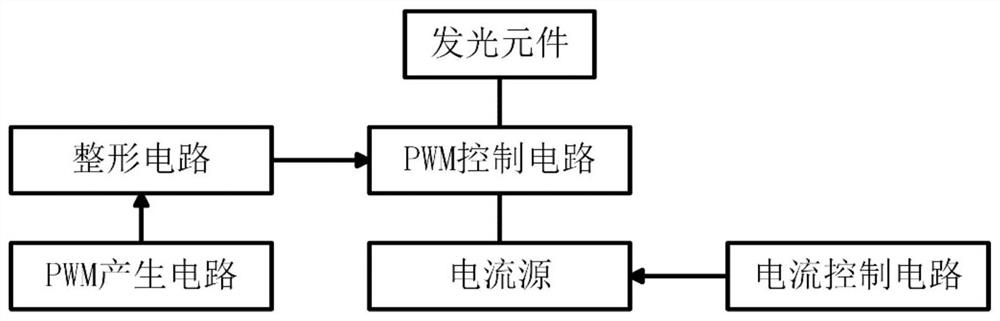

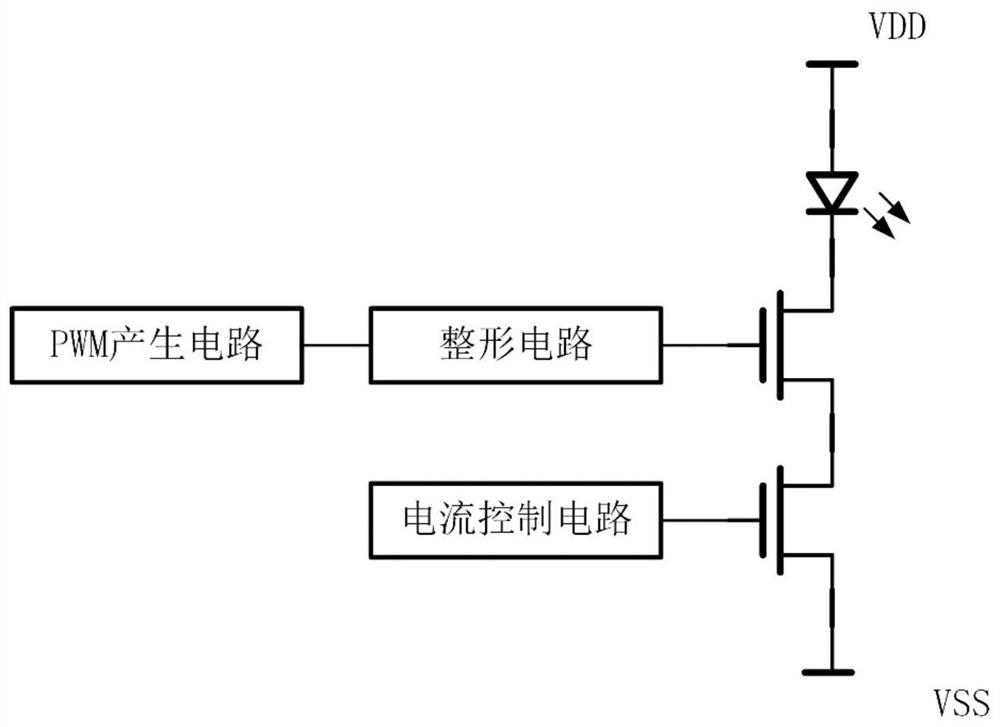

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

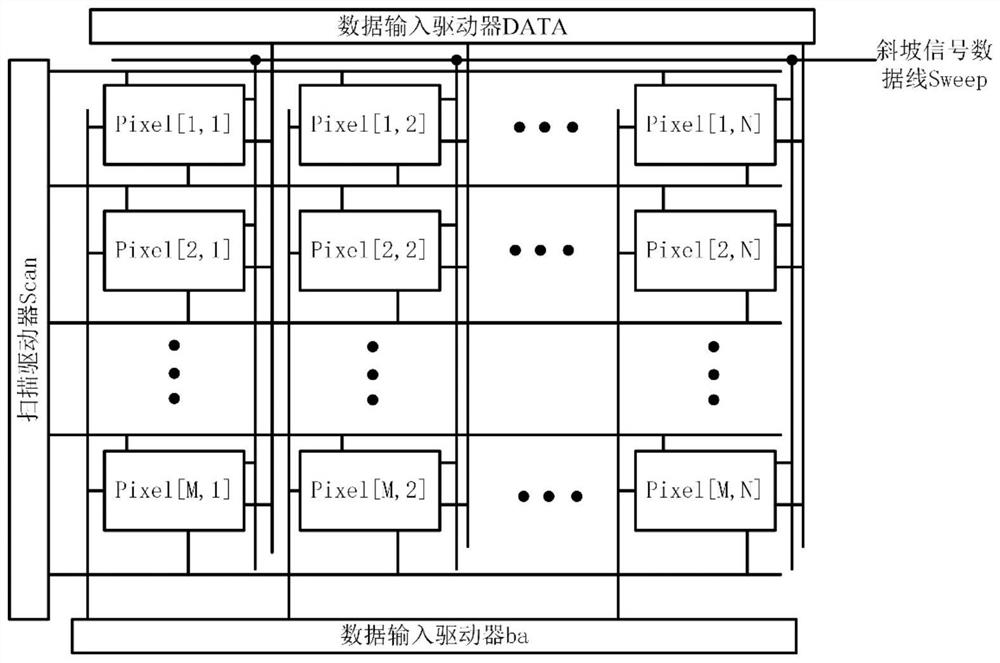

[0054] like image 3 As shown, the structure of an active electroluminescent display is basically composed of a pixel array part Pixel, a scan driver Scan, a data input driver DATA, and a data input driver ba. The pixel array components are connected to the scan lines SCAN arranged in rows, the first data signal lines and the second data signal lines arranged in columns, and the pixel array components also include a plurality of power lines for providing the necessary power for the pixel operation. Low-potential power supply VSS and high-potential power supply VDD. The first data signal line required for the operation of the pixel is used to control the pulse width of the PWM signal, the second data signal line is used to control the output current of the current source, the low-potential power supply VSS is also used for grounding, and the high-potential power supply VDD is used to supply the The pixel provides power supply, the first data signal line is the output of the da...

Embodiment 2

[0083] like image 3 As shown, the structure of the active electroluminescent display of this embodiment 2 basically consists of a pixel array component Pixel, a scan driver Scan, a data input driver DATA, and a data input driver ba. The pixel array components are all connected to the scan lines SCAN arranged in rows, the first data signal lines and the second signal data lines arranged in columns, and the pixel array components also include a plurality of power lines for providing the necessary power for the pixel operation. Low-potential power supply VSS and high-potential power supply VDD. The first data signal line required for the operation of the pixel is used to control the pulse width of the PWM signal, the second data signal line is used to control the output current of the current source, the low-potential power supply VSS is also used for grounding, and the high-potential power supply VDD is used to supply the The pixel provides the power supply.

[0084] The disp...

Embodiment 3

[0098] like Figure 8 As shown, the structure of an active electroluminescent display in this embodiment 3 basically consists of a pixel array component Pixel, a scan driver Scan, a data input driver DATA, and a data input driver ba. The pixel array components are connected to the scan lines SCAN arranged in rows, the first data signal lines and the second data signal lines arranged in columns, and the pixel array components also include a plurality of power lines for providing the necessary power for the pixel operation. Low-potential power supply VSS and high-potential power supply VDD. The first data signal line required for the operation of the pixel is used to control the pulse width of the PWM signal, the second data signal line is used to control the output current of the current source, the low-potential power supply VSS is also used for grounding, and the high-potential power supply VDD is used to supply the The pixel provides power supply, the first data signal line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com