Skateboard wheel with high resilience, high comfort and high wear resistance and processing method thereof

A technology with high wear resistance and processing methods, which is applied in the direction of skateboards, ice skating, roller skates, etc., to achieve the effects of improving comfort, increasing rebound performance, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

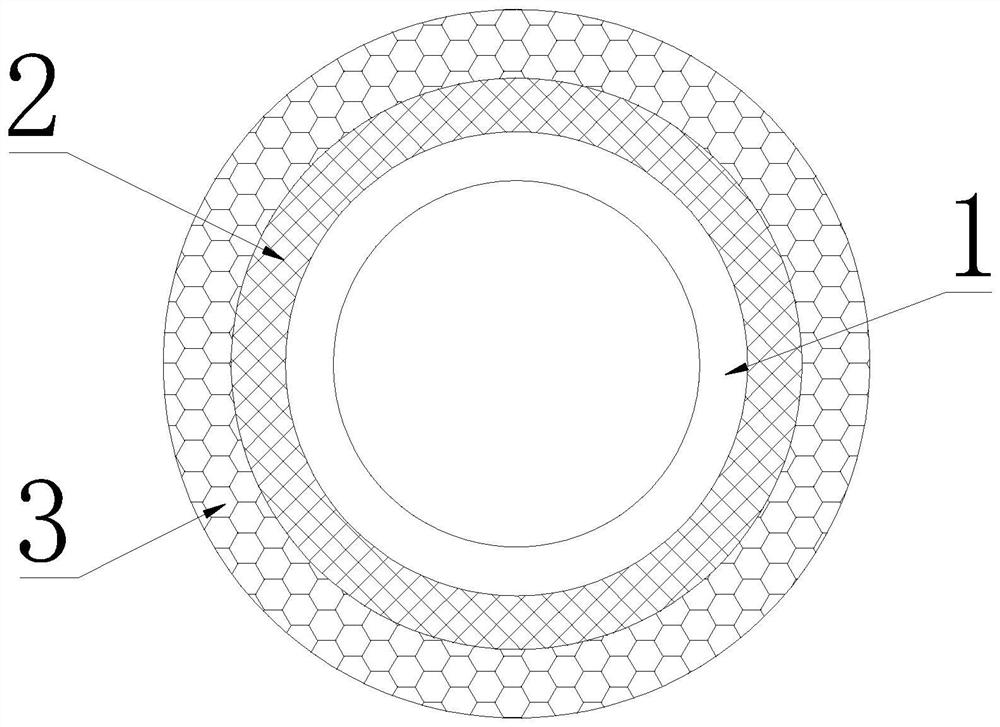

[0035] like figure 1 As shown, the present invention proposes a skateboard wheel with high resilience, high comfort and high wear resistance, including a hub 1, an intermediate body 2 and an elastic body 3;

[0036] The intermediate body 2 is coated on the outer side of the hub 1; the elastic body 3 is coated on the outer side of the intermediate body 2; wherein, the hub 1, the intermediate body 2 and the elastic body 3 are all made of polyurethane; the components of the polyurethane include tetrahydrofuran polyether, diisocyanate alcohol and 1,4 butanediol.

[0037] In an optional embodiment, in parts by weight, the polyurethane material used to make the hub 1 is composed of 95-4 parts of tetrahydrofuran polyether, 117 parts of diisocyanate alcohol and 11.5 parts of 1,4-butanediol.

[0038] In an optional embodiment, the hardness range of the hub 1 is 60 HRD.

[0039] In an optional embodiment, by weight, the components of the polyurethane material used to make the intermed...

Embodiment 2

[0056] like figure 1 As shown, the present invention proposes a skateboard wheel with high resilience, high comfort and high wear resistance, including a hub 1, an intermediate body 2 and an elastic body 3;

[0057] The intermediate body 2 is coated on the outer side of the hub 1; the elastic body 3 is coated on the outer side of the intermediate body 2; wherein, the hub 1, the intermediate body 2 and the elastic body 3 are all made of polyurethane; the components of the polyurethane include tetrahydrofuran polyether, diisocyanate alcohol and 1,4 butanediol.

[0058] In an optional embodiment, by weight, the components of the polyurethane material used to make the hub 1 are: 100 parts of tetrahydrofuran polyether, 123 parts of diisocyanate alcohol and 13.5 parts of 1,4 butanediol.

[0059] In an optional embodiment, the hardness range of the hub 1 is 70 HRD.

[0060]In an optional embodiment, in parts by weight, the components of the polyurethane material used to make the in...

Embodiment 3

[0077] like figure 1 As shown, the present invention proposes a skateboard wheel with high resilience, high comfort and high wear resistance, including a hub 1, an intermediate body 2 and an elastic body 3;

[0078] The intermediate body 2 is coated on the outer side of the hub 1; the elastic body 3 is coated on the outer side of the intermediate body 2; wherein, the hub 1, the intermediate body 2 and the elastic body 3 are all made of polyurethane; the components of the polyurethane include tetrahydrofuran polyether, diisocyanate alcohol and 1,4 butanediol.

[0079] In an optional embodiment, by weight, the components of the polyurethane material used to make the hub 1 are: 105 parts of tetrahydrofuran polyether, 1128 parts of diisocyanate alcohol and 15.5 parts of 1,4 butanediol.

[0080] In an optional embodiment, the hardness range of the hub 1 is 80 HRD.

[0081] In an optional embodiment, in parts by weight, the components of the polyurethane material used to make the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com