Antibacterial filtering fabric and preparation method thereof

A technology for fabrics and raw materials, applied in the field of antibacterial filter fabrics and their preparation, can solve the problems of peculiar smell, poor control of bacterial and virus contamination, limited treatment and control of patients' exhaled germs, etc., and achieves degradation of organic matter, efficient adsorption and removal. Bacterial virus, reducing the effect of secondary diffusion and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

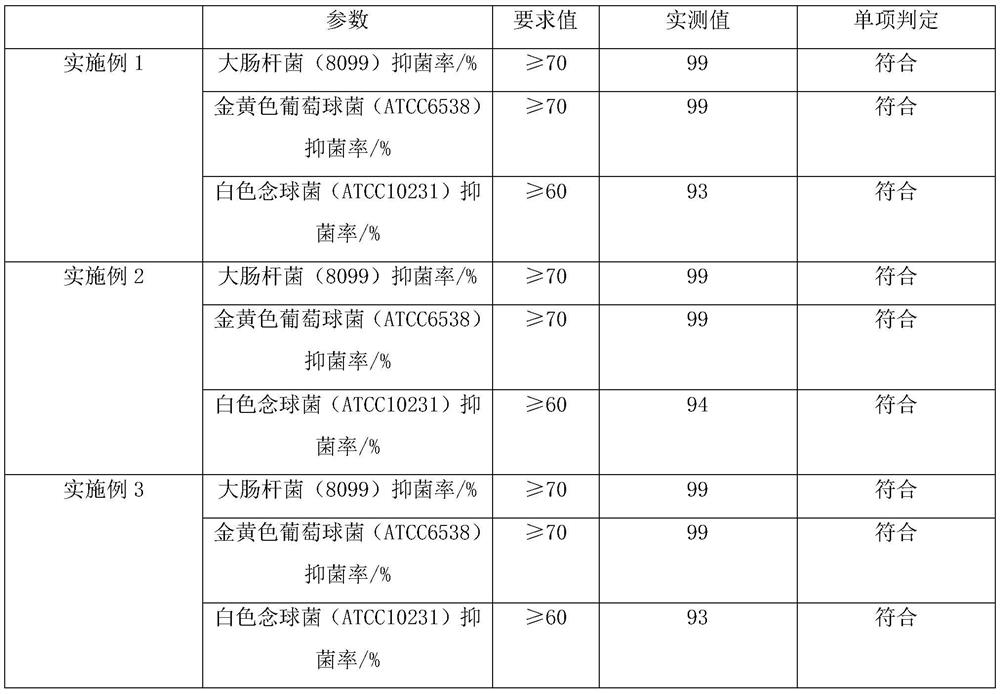

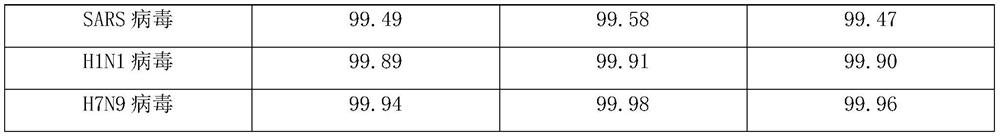

Examples

Embodiment 1

[0024] An antibacterial filter fabric, the antibacterial filter fabric is made of the following raw material components in parts by weight:

[0025] 80 parts of high melt index polypropylene, 4 parts of nano-silver ion powder, 2 parts of PP static masterbatch, 1 part of bamboo charcoal powder, 1 part of nano-titanium dioxide powder, and 0.6 parts of diffusing agent NNO.

[0026] The melt index of the high melt index polypropylene is 1500.

[0027] The particle diameter of the bamboo charcoal powder is 0.1 μm, and the particle diameter of 1-3 parts of the nano titanium dioxide powder is 0.1 μm.

[0028] The preparation method of the above-mentioned antibacterial filter fabric, the steps are as follows:

[0029] S1. Add nano-silver ion powder, PP electrostatic masterbatch, bamboo charcoal powder, nano-titanium dioxide powder, and diffusing agent NNO to high-melt-index polypropylene, and mix evenly to prepare melt-blown raw materials;

[0030] S2. Melt-extruding the melt-blown ...

Embodiment 2

[0036] An antibacterial filter fabric, the antibacterial filter fabric is made of the following raw material components in parts by weight:

[0037] 85 parts of high melt index polypropylene, 6 parts of nano-silver ion powder, 3 parts of PP static masterbatch, 2 parts of bamboo charcoal powder, 2 parts of nano-titanium dioxide powder, and 0.7 parts of diffusing agent NNO.

[0038] The melt index of the high melt index polypropylene is 1500.

[0039] The particle diameter of the bamboo charcoal powder is 0.1 μm, and the particle diameter of 1-3 parts of the nano titanium dioxide powder is 0.1 μm.

[0040] The preparation method of the above-mentioned antibacterial filter fabric, the steps are as follows:

[0041] S1. Add nano-silver ion powder, PP electrostatic masterbatch, bamboo charcoal powder, nano-titanium dioxide powder, and diffusing agent NNO to high-melt-index polypropylene, and mix evenly to prepare melt-blown raw materials;

[0042] S2. Melt-extruding the melt-blow...

Embodiment 3

[0048] An antibacterial filter fabric, the antibacterial filter fabric is made of the following raw material components in parts by weight:

[0049] 90 parts of high melt index polypropylene, 8 parts of nano-silver ion powder, 4 parts of PP static masterbatch, 3 parts of bamboo charcoal powder, 3 parts of nano-titanium dioxide powder, and 0.8 parts of diffusing agent NNO.

[0050] The melt index of the high melt index polypropylene is 1500.

[0051] The particle diameter of the bamboo charcoal powder is 0.1 μm, and the particle diameter of 1-3 parts of the nano titanium dioxide powder is 0.1 μm.

[0052] The preparation method of the above-mentioned antibacterial filter fabric, the steps are as follows:

[0053] S1. Add nano-silver ion powder, PP electrostatic masterbatch, bamboo charcoal powder, nano-titanium dioxide powder, and diffusing agent NNO to high-melt-index polypropylene, and mix evenly to prepare melt-blown raw materials;

[0054] S2. Melt-extruding the melt-blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com