Automatic spraying device and method based on visual 3D reconstruction

An automatic spraying and 3D technology, applied in spraying devices and other directions, can solve problems such as inability to fit components, labor costs, and programming workload, and achieve high spray coverage, low overall cost, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

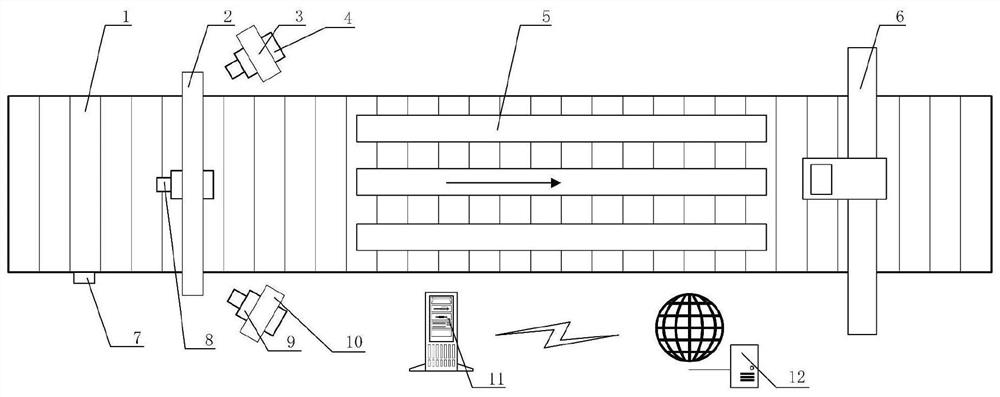

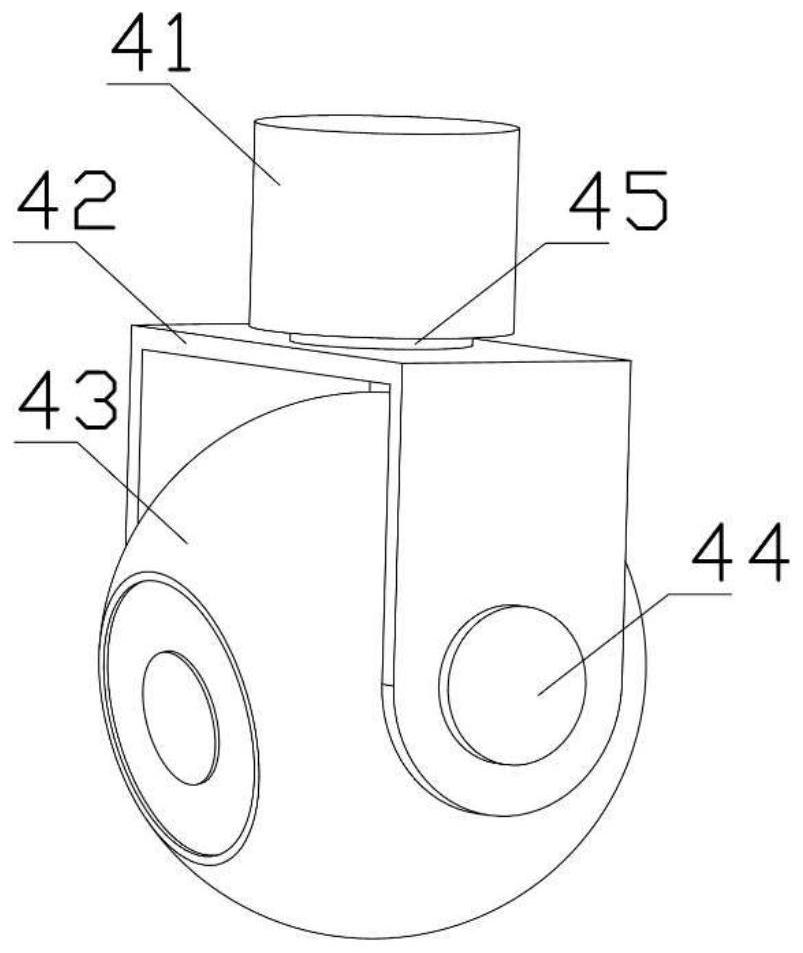

[0063] like Figure 1 to Figure 10 As shown, it includes an assembly line conveyor belt 1 and a camera group for conveying and detecting the components 5 to be sprayed. The assembly line conveyor belt 1 conveys multiple components side by side at a speed of 0.01m / s to 0.05m / s. The longitudinal spacing of components between groups is maintained at about 1m. The horizontal spacing of components within each group is related to the height of the components, the installation position of the camera, etc., and the blind area of the camera's field of view is as small as possible. The camera group includes a first camera 8 disposed directly above the assembly line conveyor 1, a second camera 4 disposed on one side of the assembly line conveyor 1, and a third camera 9 disposed on the other side of the assembly line conveyor 1;

[0064] A position sensor 7 is provided on one side of the assembly line conveyor belt 1, and the position sensor 7 is used to collect the pose and speed data ...

Embodiment 2

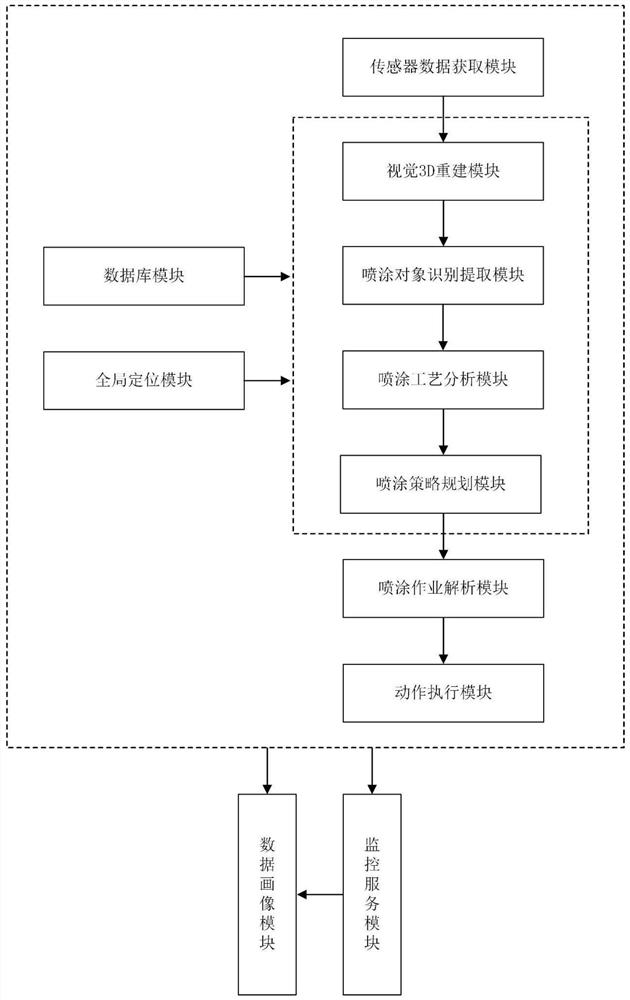

[0086] An automatic spraying method based on visual 3D reconstruction, comprising the following steps:

[0087] Information input: 3D point cloud model templates of several spraying components, spraying process parameters, such as paint film thickness, spraying speed, line speed, longitudinal interval of spraying trajectory, spraying pressure, spray gun type, etc., and hyperparameters of point cloud algorithm are pre-entered in the database module , such as template matching threshold, number of iterations, search radius, number of cells, threshold of outliers, sampling number and other information are entered into the spraying process database;

[0088] Component transportation: Arrange several components 5 of the same type to be sprayed side by side on the assembly line conveyor belt 1 at a certain interval, and the assembly line conveyor belt 1 is transported at a certain rate;

[0089] Data collection: the first camera 8, the second camera 4, and the third camera 9 collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com