Methiopyrisulfuron compound water dispersible granule

A technology of methylthiosulfuron and dispersible granules, applied in the directions of biocides, biocides, animal repellents, etc., can solve problems such as no reports on the development of water dispersible granules, and achieve increased spray coverage and improved effective utilization. rate, the effect of promoting rapid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

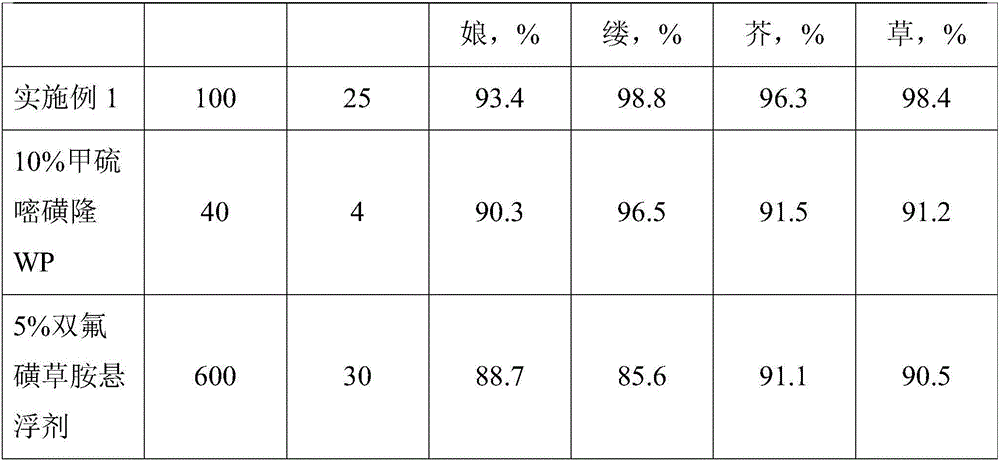

Embodiment 1

[0022] thiosulfuron-methyl 20kg, florasulam 5kg, sodium lauryl sulfate 2kg, sodium lignosulfonate 4kg, silicone surfactant Silwet408 3kg, starch 0.6kg, fumed silica 0.1kg and 65.3kg Light calcium carbonate.

[0023] Preparation:

[0024] Soak, wash, and stir the thiosulfuron-methyl original drug in 0.1wt% sodium bicarbonate solution, filter and dry it for later use; dry the thiosulfuron-methyl original drug, florasulam, and dodecane according to the formula Sodium bisulphate, sodium lignosulfonate, silicone surfactant Silwet408, starch, fumed silicon dioxide and light calcium carbonate are fully mixed, coarsely crushed, remixed, pulverized by a jet mill, and mixed in a conical mixer , through a 300-mesh standard sieve to obtain fine powder, and then add water to the fine powder, knead, extrude and granulate, and dry at 40°C to obtain thiosulfuron-methyl compound water-dispersible granules.

Embodiment 2

[0026] thiosulfuron-methyl 23kg, florasulam 5kg, saponin powder 4kg, calcium lignosulfonate 5kg, silicone surfactant Silwet408 4kg, starch 4.2kg, fumed silica 0.6kg and diatomite 54.2kg .

[0027] Preparation:

[0028] Soak, wash, and stir the thiosulfuron-methyl original drug with 0.3wt% sodium bicarbonate solution, filter and dry it for later use; prepare the dried thiosulfuron-methyl original drug, diflusulam, and saponins powder according to the formula , calcium lignosulfonate, silicone surfactant Silwet408, starch, fumed silica and diatomaceous earth are fully mixed, coarsely pulverized, remixed, pulverized by a jet mill, mixed in a conical mixer, passed through a 325-mesh Standard sieve to obtain fine powder, then add water to the fine powder and knead, extrude and granulate, and dry at 45°C to obtain thiosulfuron-methyl compound water-dispersible granules.

Embodiment 3

[0030] Thisulfuron-methyl 28kg, florasulam 7kg, alkylphenol polyoxyethylene ether 8kg, Morwet-450 7kg, silicone surfactant Silwet408 6kg, starch 4.0kg, fumed silica 0.5kg and 39.5kg ammonium sulfate.

[0031] Preparation:

[0032] Soak, wash, and stir the original drug of thiosulfuron-methyl with 0.5wt% sodium bicarbonate solution, filter and dry it for later use; prepare the original drug of thiosulfuron-methyl, florasulam, and alkylphenol after drying according to the formula Polyoxyethylene ether, Morwet-450, silicone surfactant Silwet408, starch, fumed silicon dioxide and ammonium sulfate are fully mixed, coarsely pulverized, remixed, pulverized by a jet mill, mixed in a conical mixer, passed through 400 Sieve the fine powder according to the target standard, then add water to the fine powder and knead, extrude and granulate, and dry at 55°C to obtain the thiosulfuron-methyl compound water-dispersible granule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com