Wet desulphurization absorption tower

A wet desulfurization and absorption tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult nozzle arrangement, main pipe flushing, flue gas escape, etc., to improve spray coverage and The effect of desulfurization efficiency, low working pressure and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

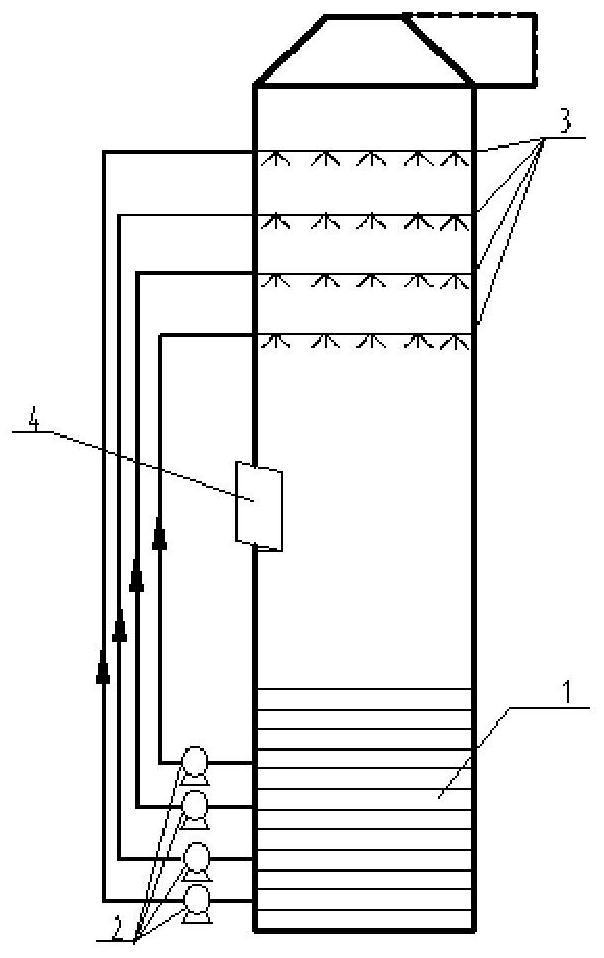

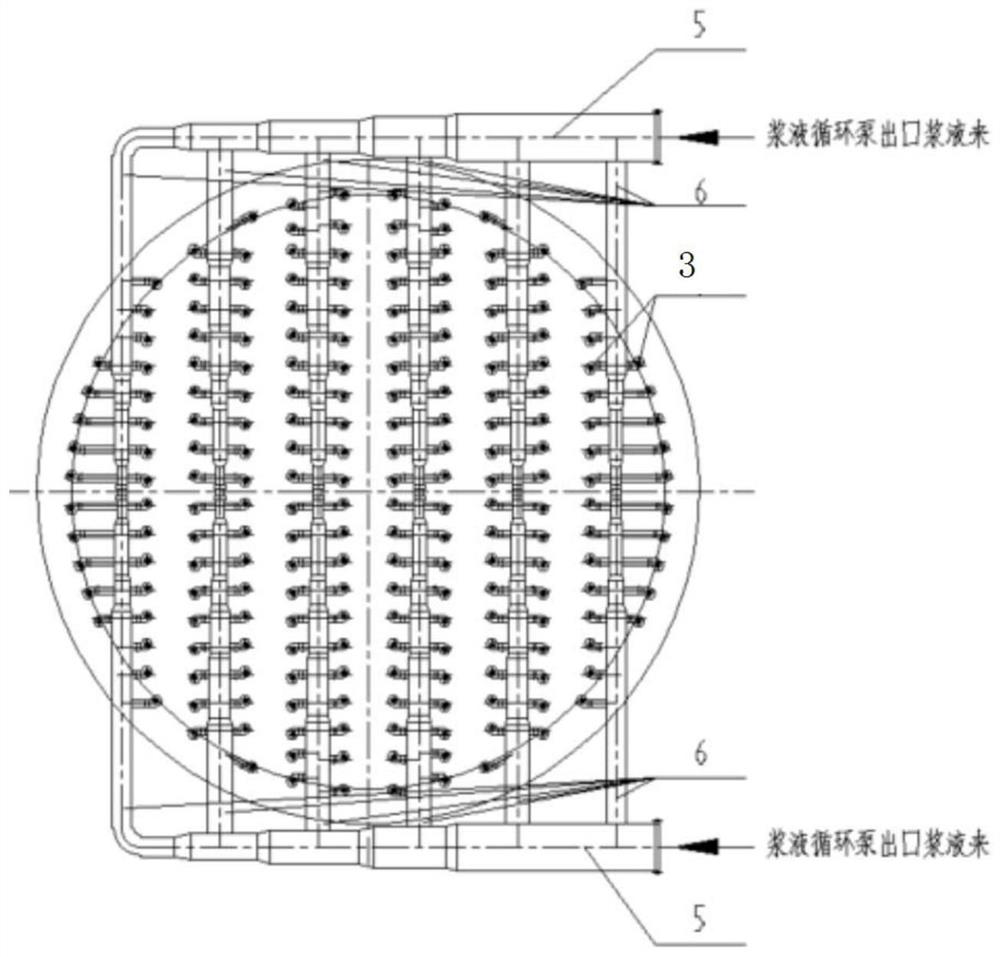

[0019] refer to figure 1 and figure 2 , the wet desulfurization absorption tower of the present invention includes a tower body 1, a main spray pipe 5 outside the tower, and a number of spray branch pipes 6 inside the tower body 1, wherein the side of the tower body 1 is provided with flue gas The inlet 4 and the spray branch pipe 6 in each tower are connected with a number of high-efficiency atomizing nozzles 3, and the slurry outlet at the bottom of the tower body 1 is connected with the spray main pipe 5 outside the tower through the slurry circulation pump 2, wherein the high-efficiency mist The working pressure of the atomizing nozzle 3 is less than 60kPa, and the flow rate of the high-efficiency atomizing nozzle 3 is less than 30m 3 / h.

[0020] The spray branch pipes 6 in each tower are divided into several groups, wherein the spray branch pipes 6 in each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com