Cantilever and dust removal equipment for large box girder manufacturing workshop

A technology for making workshops and cantilevers, which is applied in the field of dust removal equipment and cantilevers, and can solve the problem that the suction arm cannot meet the coverage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the above-mentioned technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

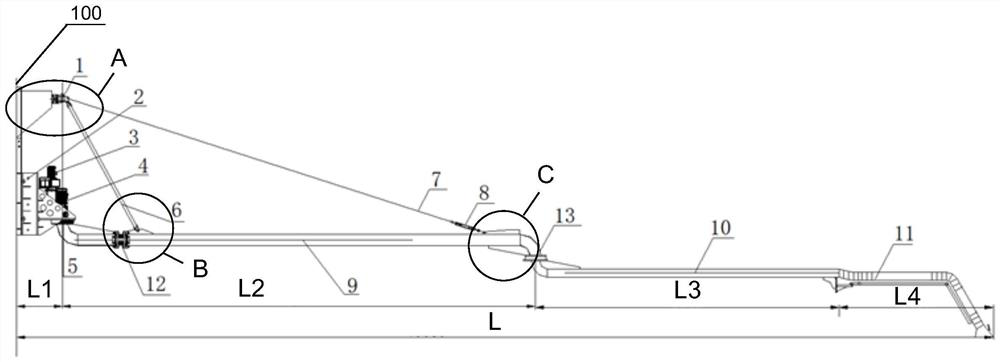

[0036] to combine figure 1 As shown, a cantilever used in a large-scale box girder manufacturing workshop provided by the present invention includes a driving arm 9 , a manual arm 10 , a suction arm 11 , a cantilever support 2 and a suspension support 1 .

[0037] The cantilever support 2 is arranged on the column 100 , and the cantilever support 2 is provided with a drive motor 4 and an induced draft fan 3 , and the drive motor 4 is used to control the rotation of the drive arm 9 .

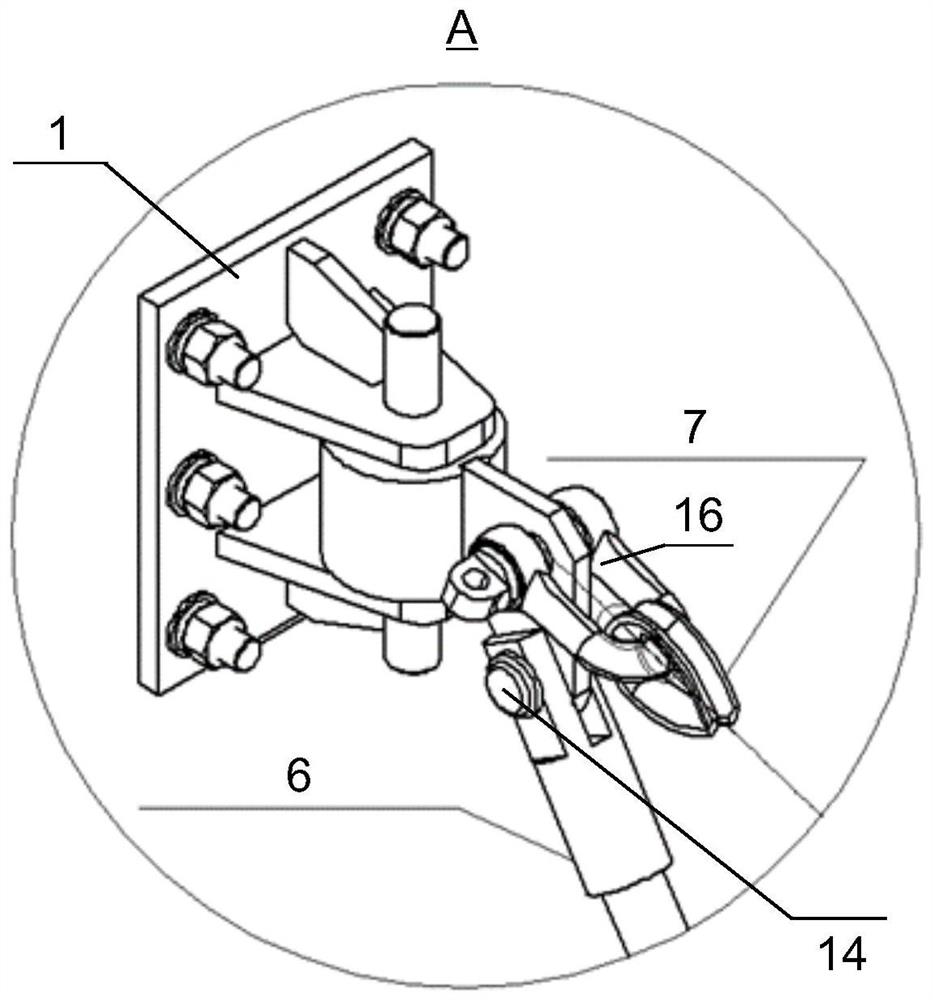

[0038] The suspension support 1 is also arranged on the column 100, and is located above the cantilever support 2, and the suspension support 1 is connected with a rigid suspension 6 and a flexible suspension 7.

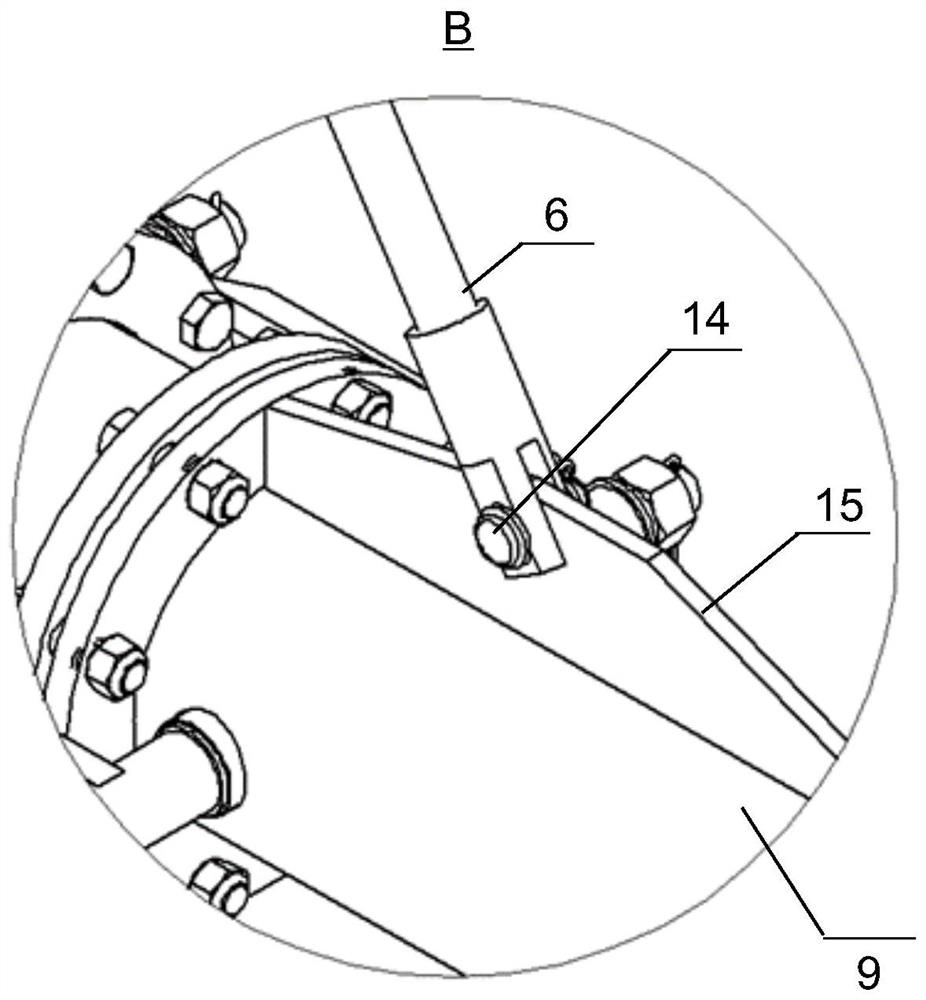

[0039] Rigid suspension 6 is connected on the rear e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap