A kind of harmless treatment method of antibiotic bacteria residue

A technology of antibiotic bacteria residue and harmless treatment, applied in the direction of microbial treatment, combined biological treatment, biological organic part treatment, etc., can solve secondary pollution and other problems, and achieve the effect of simple method and difficult treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

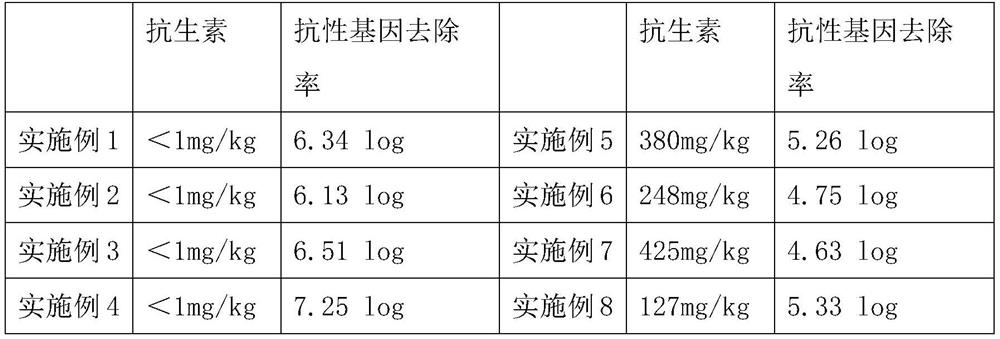

Examples

Embodiment 1

[0029] Take antibiotic residue with gentamicin residue of 2600mg / kg, adjust the pH to 4.5, and heat to 50°C with a moisture content of 85%, and then follow the molar ratio of antibiotic: persulfate: copper = 1:50:8 Ammonium persulfate and copper powder were added to the antibiotic bacterial residue in turn, mixed uniformly, and then irradiated with 250 nm ultraviolet light, and oxidized under the condition of 200 KHz ultrasonic frequency for 30 min. The antibiotic slag must be treated harmlessly.

[0030] The preparation method of copper powder: adding nano-iron with an equimolar amount of copper ions to a copper sulfate solution with a concentration of 10g / L at 40°C under stirring conditions, stirring continuously until the solution is reddish-brown, and then suction filtration to obtain the upper layer material, drying That is, copper powder particles.

Embodiment 2

[0032] Take the antibiotic slag to adjust the pH value to 5, heat to 40°C after the moisture content is 90%, and then add ammonium persulfate and copper to the antibiotic slag in turn according to the molar ratio of antibiotic: persulfate: copper=1:30:10 The powder was mixed uniformly and oxidized for 40min under the condition of 280nm ultraviolet irradiation and 100KHz ultrasonic frequency. The antibiotic slag must be treated harmlessly.

[0033] The preparation method of copper powder: adding nano-iron with an equimolar amount of copper ions to a copper sulfate solution with a concentration of 10g / L at 40°C under stirring conditions, stirring continuously until the solution is reddish-brown, and then suction filtration to obtain the upper layer material, drying That is, copper powder particles.

Embodiment 3

[0035] Take the antibiotic slag to adjust the pH value to 3, heat to 60 ° C after the moisture content is 80%, and then add ammonium persulfate and copper to the antibiotic slag in turn according to the molar ratio of antibiotic: persulfate: copper = 1:40:5 The powder was mixed uniformly and oxidized for 20min under the condition of 200nm ultraviolet irradiation and 150KHz ultrasonic frequency. The antibiotic slag must be treated harmlessly.

[0036] The preparation method of copper powder: adding nano-iron with an equimolar amount of copper ions to a copper sulfate solution with a concentration of 10g / L at 40°C under stirring conditions, stirring continuously until the solution is reddish-brown, and then suction filtration to obtain the upper layer material, drying That is, copper powder particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com