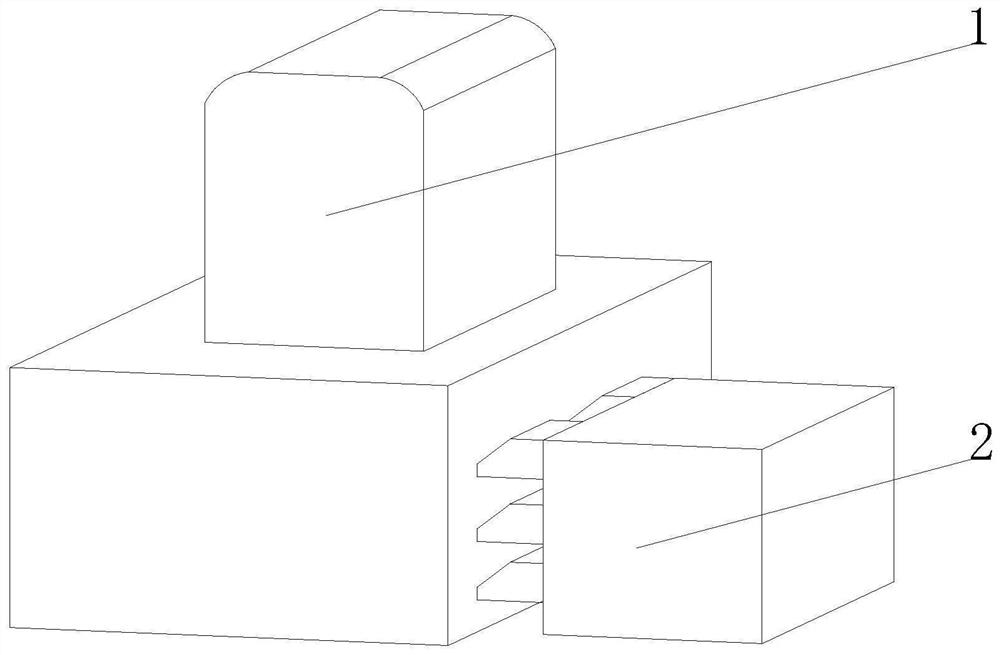

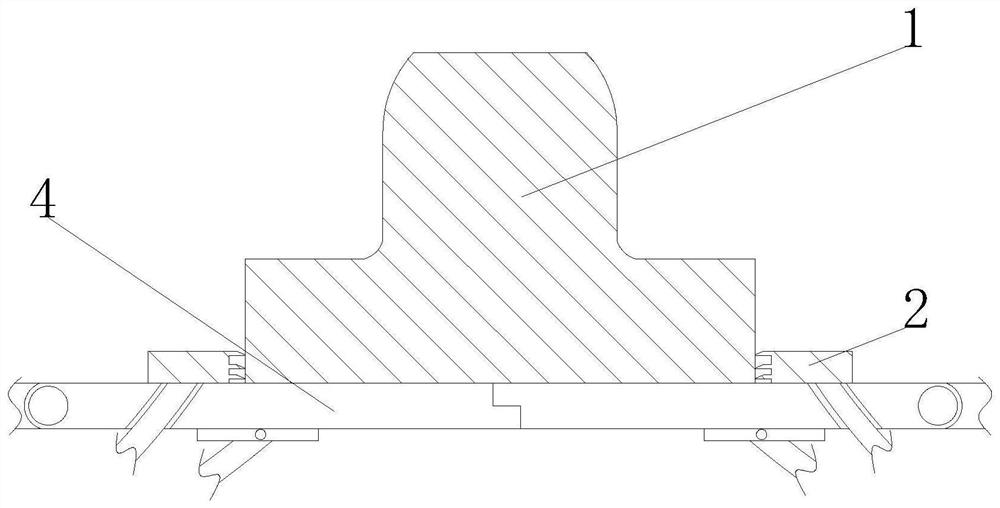

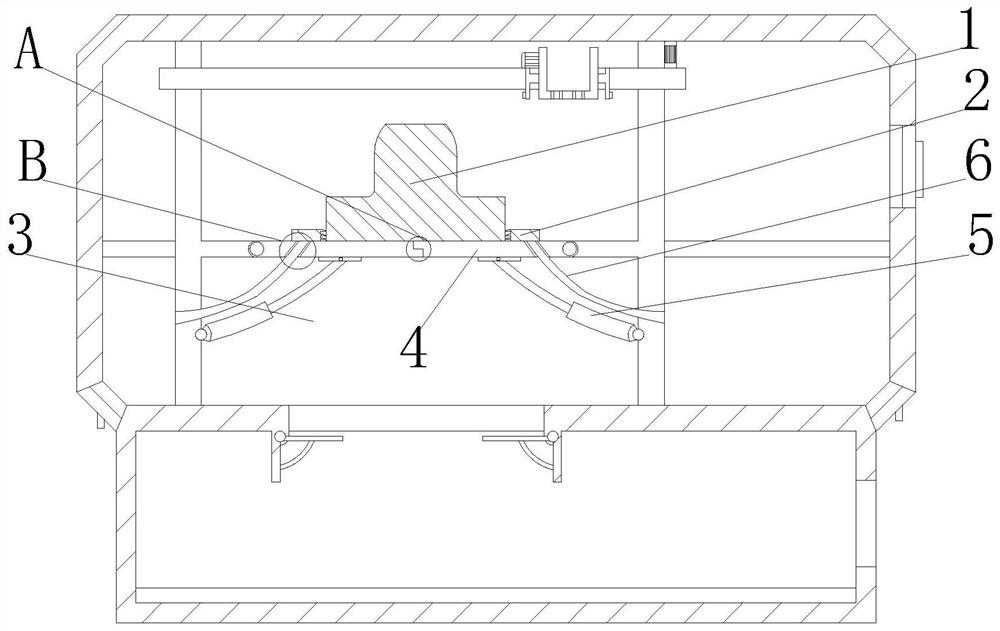

3D printing injection mold convenient to disassemble

An injection mold, 3D printing technology, applied in the direction of additive manufacturing, additive processing, etc., can solve problems such as reducing equipment work efficiency, and achieve the effect of increasing work costs, reducing cleaning time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] As an embodiment of the present invention, the first printing board a1 and the second printing board a2 are provided with a liquid outlet e1 and a liquid inlet e2 from the top and inside, and the liquid outlet e1 and the liquid inlet e2 They are all connected to the squeeze liquid bag a4 through pipelines, the larger the diameter of the outlet groove e1 from the squeeze liquid bag a4 is, the moving ball e3 is placed inside the liquid outlet groove e1, and the liquid inlet groove e2 The end away from the squeeze liquid bag a4 is connected to the infusion pump, and the squeeze liquid bag a4 is connected through the connecting pipe e4; during operation, the liquid in the squeeze liquid bag a4 is passed through by squeezing the squeeze liquid bag a4 The connecting pipe e4 is increased one by one to increase the internal pressure of the squeeze liquid bag a4 close to the liquid outlet tank e1, and the pressure inside the squeeze liquid bag a4 slowly pushes the moving ball e3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com