Horizontal punching device

A drilling device, horizontal technology, applied in the direction of transportation and packaging, boring/drilling, drilling/drilling equipment, etc., can solve the problems of impact on the life of the drilling machine, slow drilling speed, etc., and achieve convenient centering , fast cutting and reaming, and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

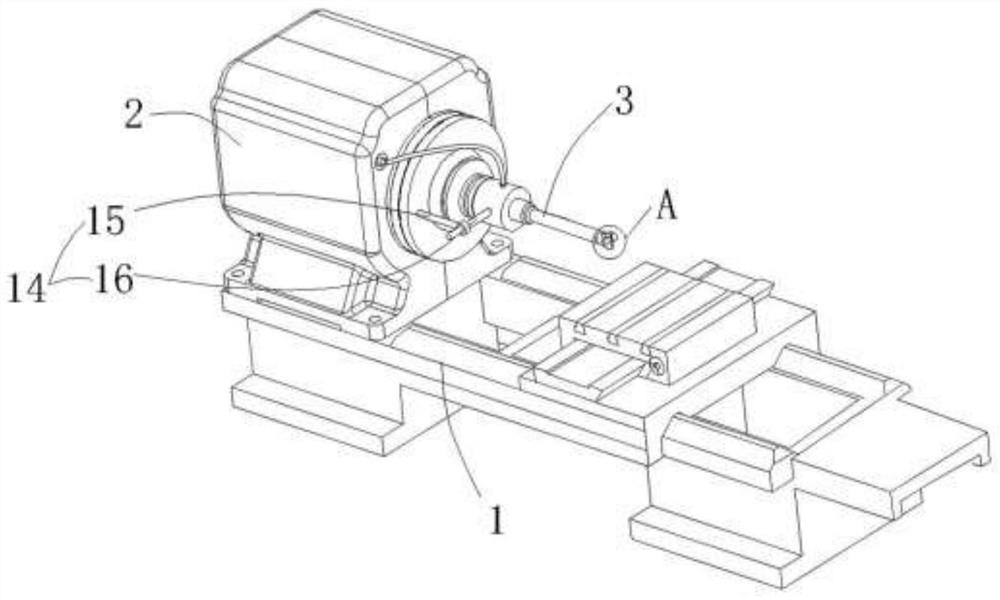

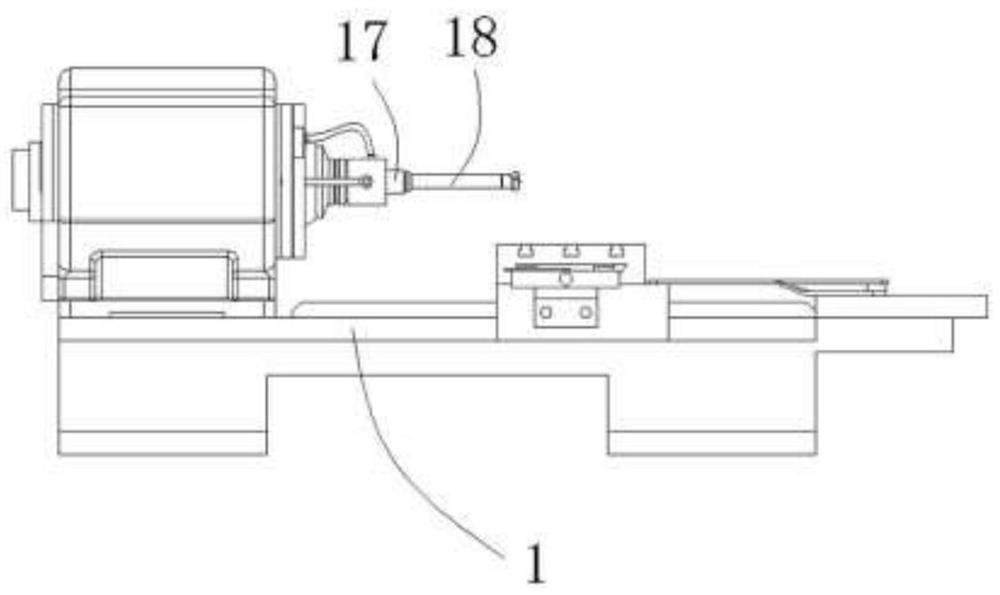

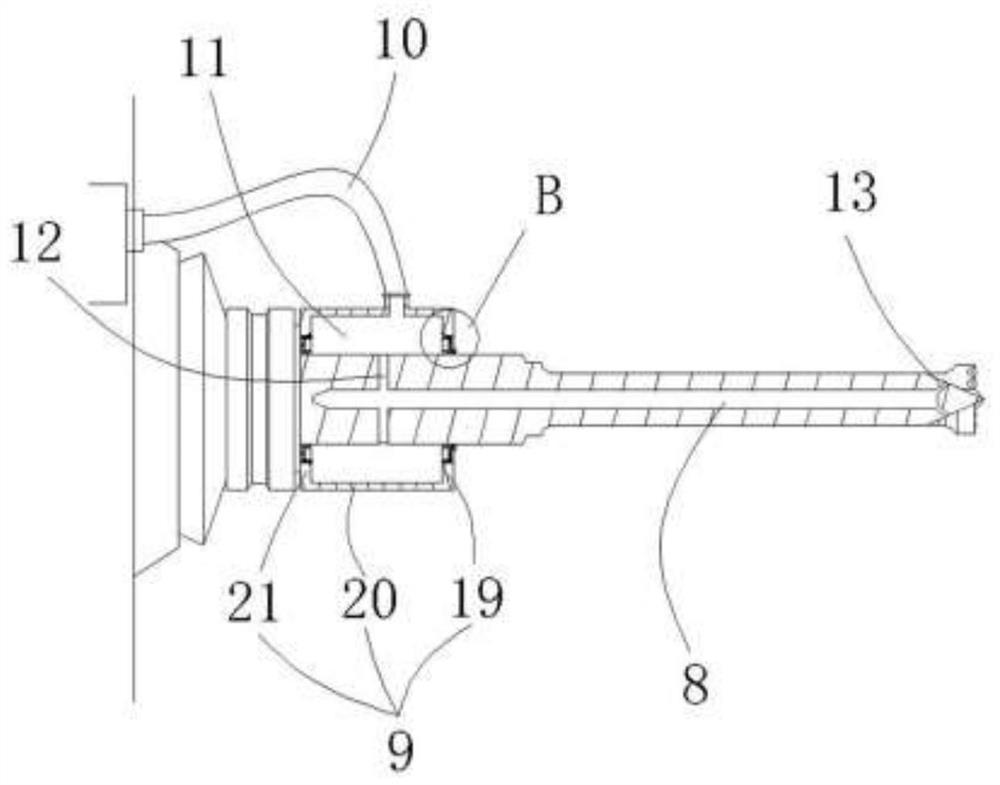

[0027] combined with Figures 1 to 5 , a horizontal punching device, comprising a horizontal body 1, a spindle box 2 is provided on one side of the horizontal body 1, a motor and a motor connected to the output shaft of the motor are arranged in the spindle box 2 Speed reduction mechanism, the output shaft outer end of the speed reduction mechanism stretches out on the right side of the main shaft box 2, the right side of the main shaft box 2 is connected with a drill rod 3 arranged transversely, and the head of the drill rod 3 is provided with a drill bit Group 4, the drill bit group 4 includes a drill bit 5 in the center and edge edges 6 on both sides, the edge edge 6 is provided with a cutting blade 7;

[0028] The drill pipe 3 is provided with a cooling passage 8, and the rear side of the drill pipe 3 is provided with an infusion sleeve 9, and the infusion sleeve 9 is connected to the liquid inlet pipe 10, and the infusion sleeve 9 is fixed on the headstock 2, so that T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com