Anti-adhesion kitchen knife

An anti-adhesion and kitchen knife technology, applied in the field of kitchen utensils, can solve problems such as hand injury, and achieve the effects of avoiding hand sliding, improving comfort, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

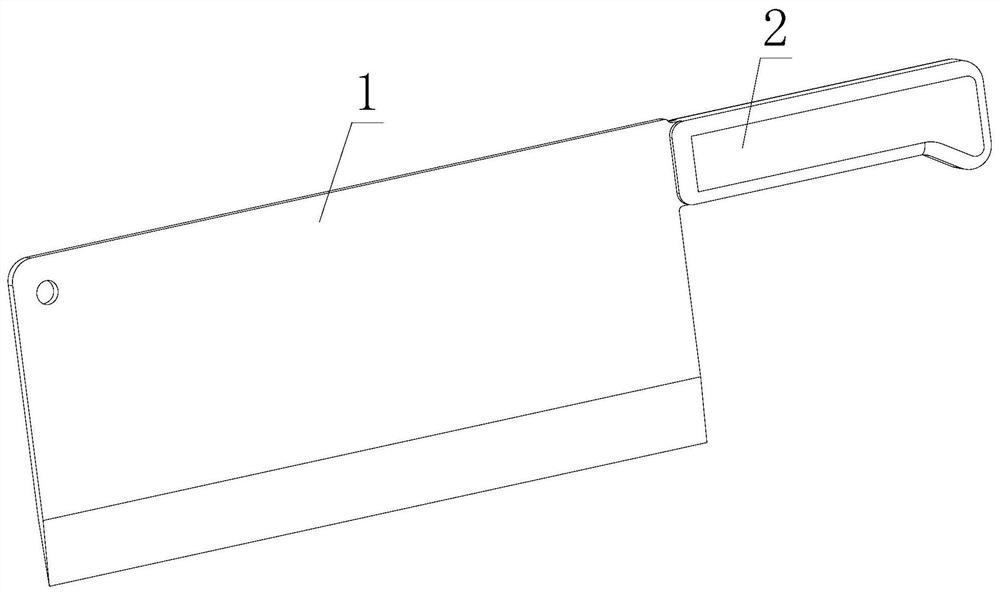

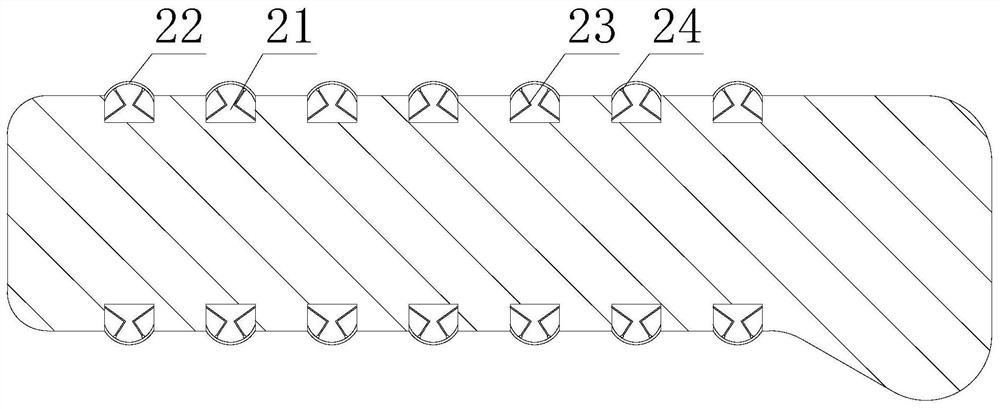

[0024] Such as figure 1 - image 3 As shown, the present invention provides an anti-adhesion kitchen knife, comprising a knife body 1, one end of the knife body 1 is fixedly connected with a knife handle 2, the upper and lower ends of the outer side of the knife handle 2 are provided with an air cavity 21, and the air cavity 21 is far away from the knife handle 2 An anti-slip film 22 is fixedly connected to one end of the air cavity 21, and a support elastic piece 23 is arranged between the side wall of the air cavity 21 and the anti-slip film 22. A bumper ball 24 is fixedly connected.

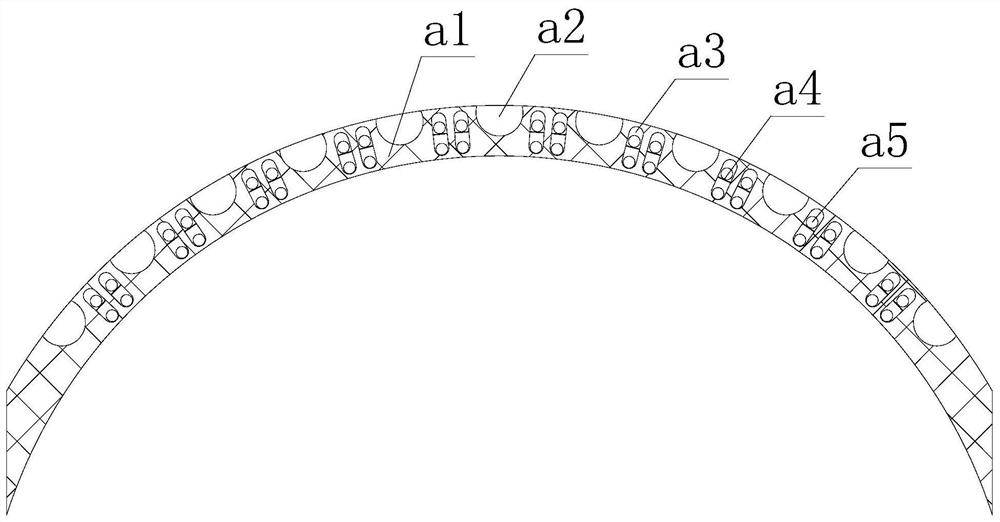

[0025] Wherein, the anti-slip film 22 is provided with a rubber layer a1 inside, and the side of the rubber layer a1 away from the air cavity 21 is provided with an extrusion chamber a2, and the inner part of the rubber layer a1 is provided with a vibration chamber a3, and the middle part of the vibration chamber a3 is fixed. The vibrating partition a4 is connected, and the vibrating chamber...

Embodiment 2

[0028] Such as Figure 4-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inside of the extrusion chamber a2 is provided with a chamber shell s1, the upper ends of both sides of the chamber shell s1 are movably connected with rollers s2, the chamber shell s1 A vibrating rod s3 is arranged inside, and both ends of the vibrating rod s3 are fixedly connected with the rubber layer a1.

[0029] Wherein, the inside of the vibrating rod s3 is provided with a connection end d1, the number of the connection ends d1 is two, a connection rod d2 is fixedly connected between the two connection ends d1, and the number of connection rods d2 set between the two connection ends d1 is Five, five connecting rods d2 are fixedly connected with percussion partitions d3, and vibration balls d4 are arranged between the five connecting rods d2.

[0030] The vibrating ball d4 is provided with a spherical shell e1 inside, the spherical shell e1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com