Cement mortar quantitative proportioning and spraying equipment for building

A technology for cement mortar and spraying equipment, which is applied to cement mixing devices, batching weighing instruments, clay preparation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

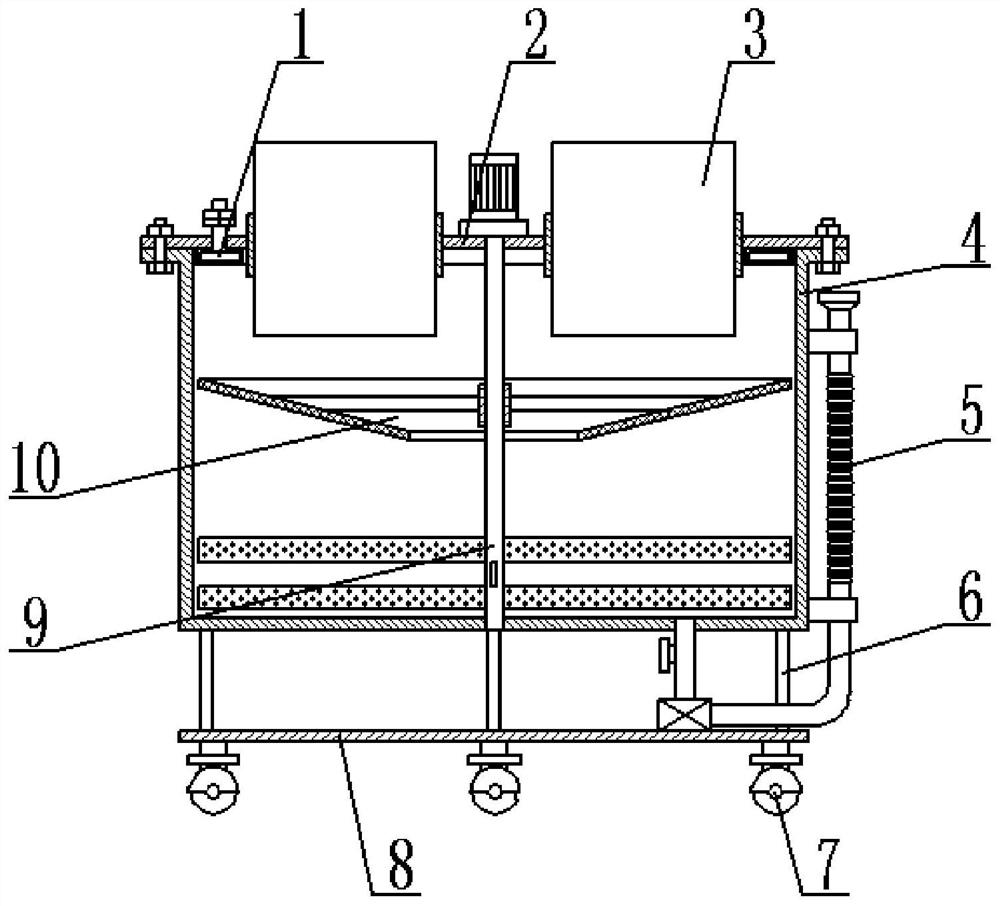

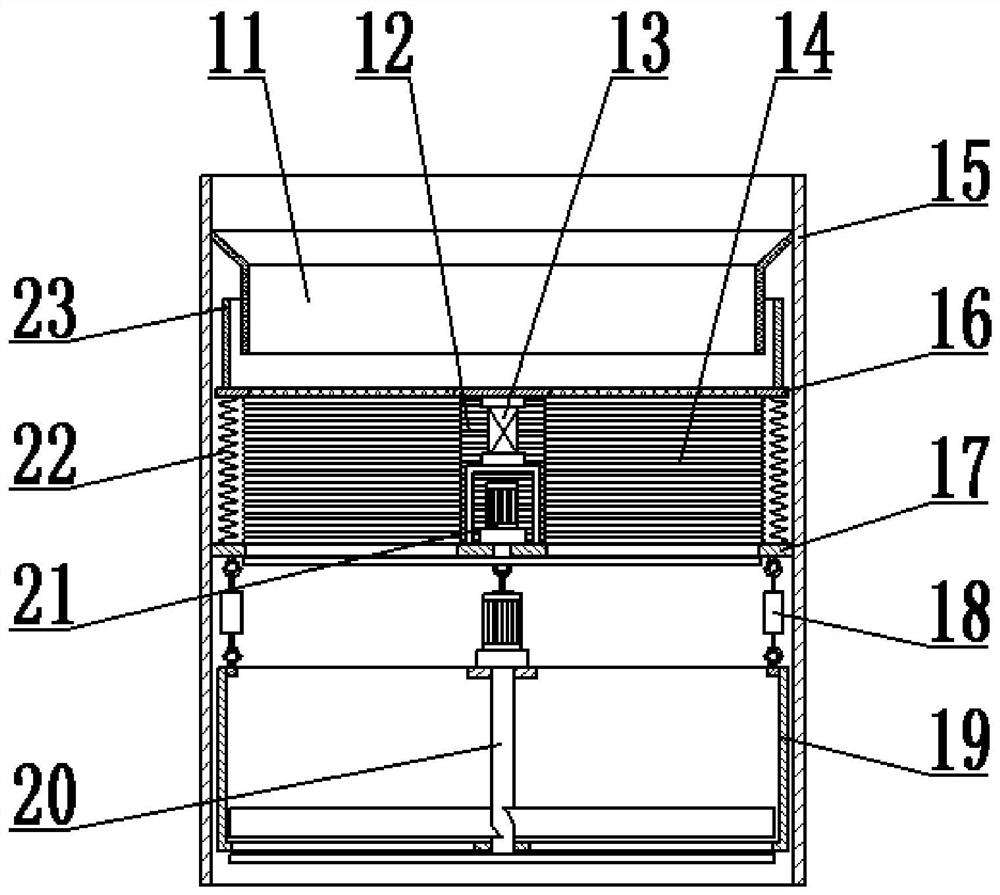

[0044] A construction of cement sand slurry for this embodiment is quantified and sprayed equipment, such as figure 1 As shown, including the mixing tank 4, the mixing tank 4 is provided as a cylindrical shape, and the top cover 2 is provided, and the top cover 2 is fixedly mounted on the mixing tank 4 by bolt. figure 2 The quantitative feed apparatus 3 of the present embodiment includes a quantitative feed barrel 15, which is disposed at both ends in which the split disk 16 is sequentially provided inside the quantitative feed barrel 15. The limit disk 17 and the reservoir 19 are disposed in the middle wall of the quantitative feed barrel 15, which is provided with a winder 21, and a limit disk 17 and a carrier 21 pair. The raw material is added to the storage cartridge 19 to limit the amount of the feed material, such as figure 2 As shown, the bottom surface of the restricted plate 17 is connected to the fixed block 29 of the top portion of the storage cartridge 19 by the four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com