Energy-saving and environment-friendly aggregate centralized feeding system

An energy-saving and environmental-friendly aggregate technology, which is applied in the sales of raw material supply devices, clay preparation devices, mixing operation control devices, etc., can solve the problems of low safety, large dust, low efficiency, etc., to reduce labor intensity, ensure air, Ensure cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

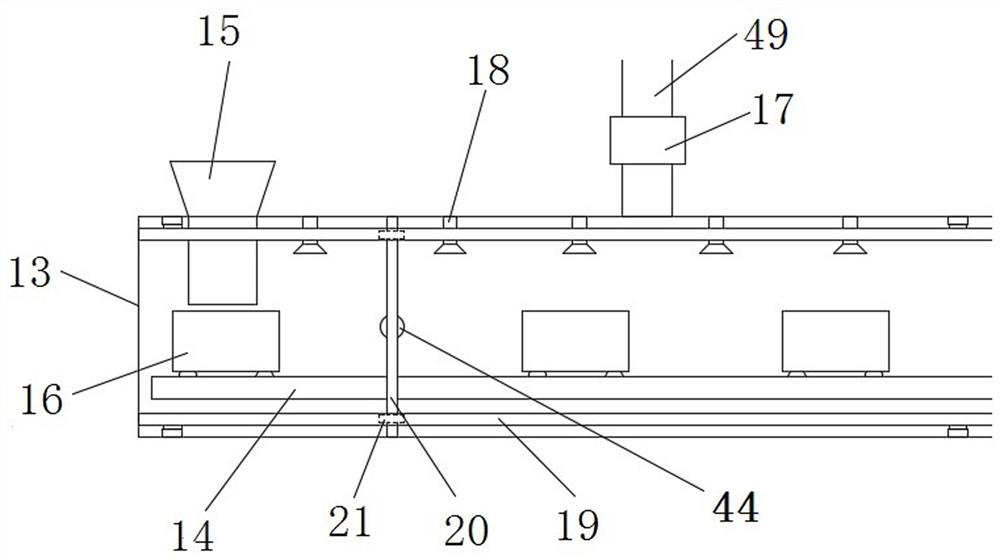

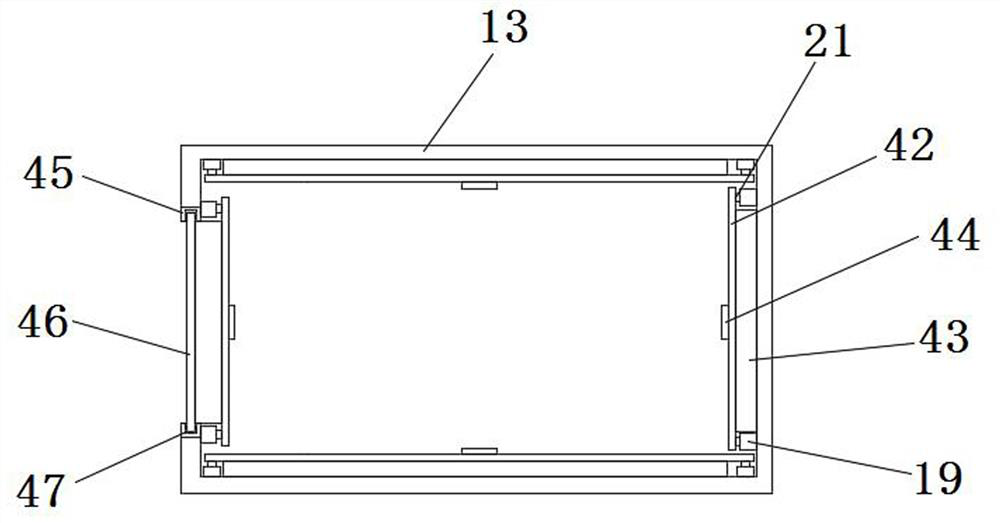

[0051] An energy-saving and environment-friendly centralized aggregate feeding system, including a discharge mechanism, a material transfer mechanism, an aggregate collection mechanism and an aggregate measurement mechanism;

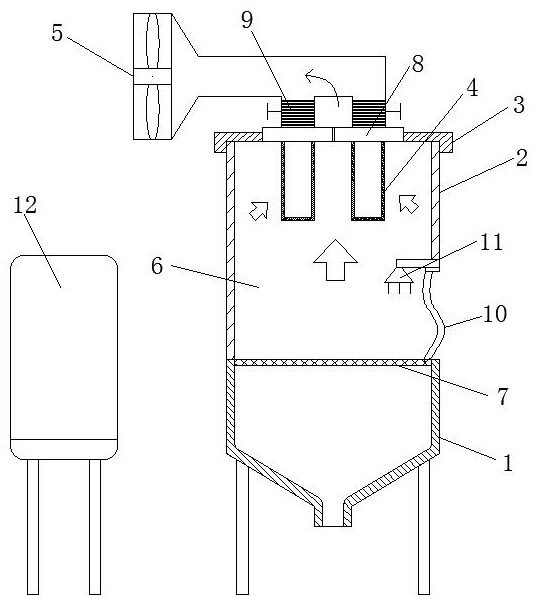

[0052] The unloading mechanism described is as figure 1 As shown, it includes a discharge hopper 1, a dust removal device 6 and a water storage tank 12. The top opening of the discharge hopper 1 is sealed and connected with the dust removal device 6, and a screen 7 is installed at the connection; the dust removal device 6 includes upper and lower openings. The box body 2, loam cake 3 and blower 5; The top opening of described box body 2 is connected with loam cake 3, and the top of loam cake 3 is provided with dust outlet 8 and is connected with blower 5, and described dust outlet The lower end of 8 is equipped with a bag support, and a dust removal bag 4 is installed in the bag support, and the dust removal bag 4 is sealed and connected with the dust ou...

Embodiment 2

[0067] Compared with Embodiment 1, the difference of this embodiment is:

[0068] The upper part of the outlet of the air extractor 5 is also provided with a sprayer B, and the sprayer B is connected to the water storage tank 12 through a pipeline equipped with a pump body.

[0069] The sprayer B is installed, and the water mist sprayed by the sprayer B can eliminate the dust gas discharged from the exhauster as the air passes through the dust bag for the third time, and further dedust the aggregate.

[0070] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0072] Compared with Embodiment 1, the difference of this embodiment is:

[0073] The track wheel assembly 28 is specifically as Figure 6 As shown, it includes a connecting rod 34, a connecting frame 35 and a roller 36; the connecting frame 35 is straddled on the circular track 26; one end of the connecting rod 34 is fixedly connected with the connecting frame 35, and the other end is connected with the slope slideway 25 ; The roller 36 is set in the connecting frame 35 and is in contact with the circular track 26 .

[0074] The rollers are distributed on the upper part and the side part of the inner surface of the connecting frame, and are used to support the track wheel assembly to move along the circular track.

[0075] The working principle of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com