Electrode for electrolysis, manufacturing method of electrode and electrolysis device

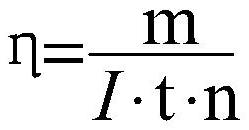

An electrolysis device and manufacturing method technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult cathode discharge, low current efficiency, etc., achieve the effects of reducing cell voltage, improving current efficiency, and solving difficult deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: Electrolyte is NiSO 4 ·7H 2 O solution, its concentration is 20g / L, and its pH value is 1 with sulfuric acid adjustment. Perform electrolysis with a current of 2A, the area of the cathode base is 10cm×10cm, and electrolyze for 1h.

[0062] Using a 410 stainless steel plate as the cathode, and attaching an N35 NdFeB magnet with a diameter of 30 mm x a thickness of 5 mm on the back of the cathode plate for magnetization, the hydrogen evolution at the cathode is significantly reduced, and the current efficiency of the cathode metal nickel electrodeposition is increased to 45%.

[0063] From the comparison of comparative example 1 and embodiment 1, it can be seen that under the same electrolytic solution and the same electrolysis conditions, embodiment 1 of the present invention is provided with a neodymium-iron-boron magnet on the back side of the cathode, and the neodymium-iron-boron magnet can be placed on the cathode. After magnetization, the current e...

Embodiment 2

[0069] Embodiment 2: Electrolyte is NiCl 2 ·6H 2 O solution, its concentration is 25g / L, and the pH value is 3 with hydrochloric acid adjustment.

[0070] Conduct electrolysis with a current of 2A, use an iron plate as the cathode, and the area of the cathode plate is 10cm×10cm. On the back of the cathode iron plate, N35 NdFeB magnets with a diameter of 30mm×thickness 5mm are attracted to magnetize the cathode iron plate, and the NdFeB magnet is placed on the back of the cathode iron plate. The surface of the boron magnet is coated with epoxy resin to prevent the electrolyte from corroding the pole plate, and the current efficiency is 81% after electrolysis for 1 hour.

[0071] From the comparison of Comparative Example 2 and Example 2, it can be seen that when the electrolyte is the same, the electrolysis conditions are the same, and epoxy resin is coated to prevent the electrolyte from corroding the pole plate, Example 2 of the present invention is due to the An NdFeB ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com