A vacuum cathode arc source device and method for depositing a coating

A cathodic arc and arc source technology, which is applied to the vacuum cathode arc source device and the coating deposited on the inner surface of the nozzle of the orbit attitude control engine, and the field of the two-component liquid rocket orbit/attitude control engine. Performance requirements and other issues to achieve the effects of prolonging life, optimizing deposition process optimization, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of vacuum cathode arc source of the present invention deposits coating on the inner surface of engine nozzle, specifically comprises the following steps:

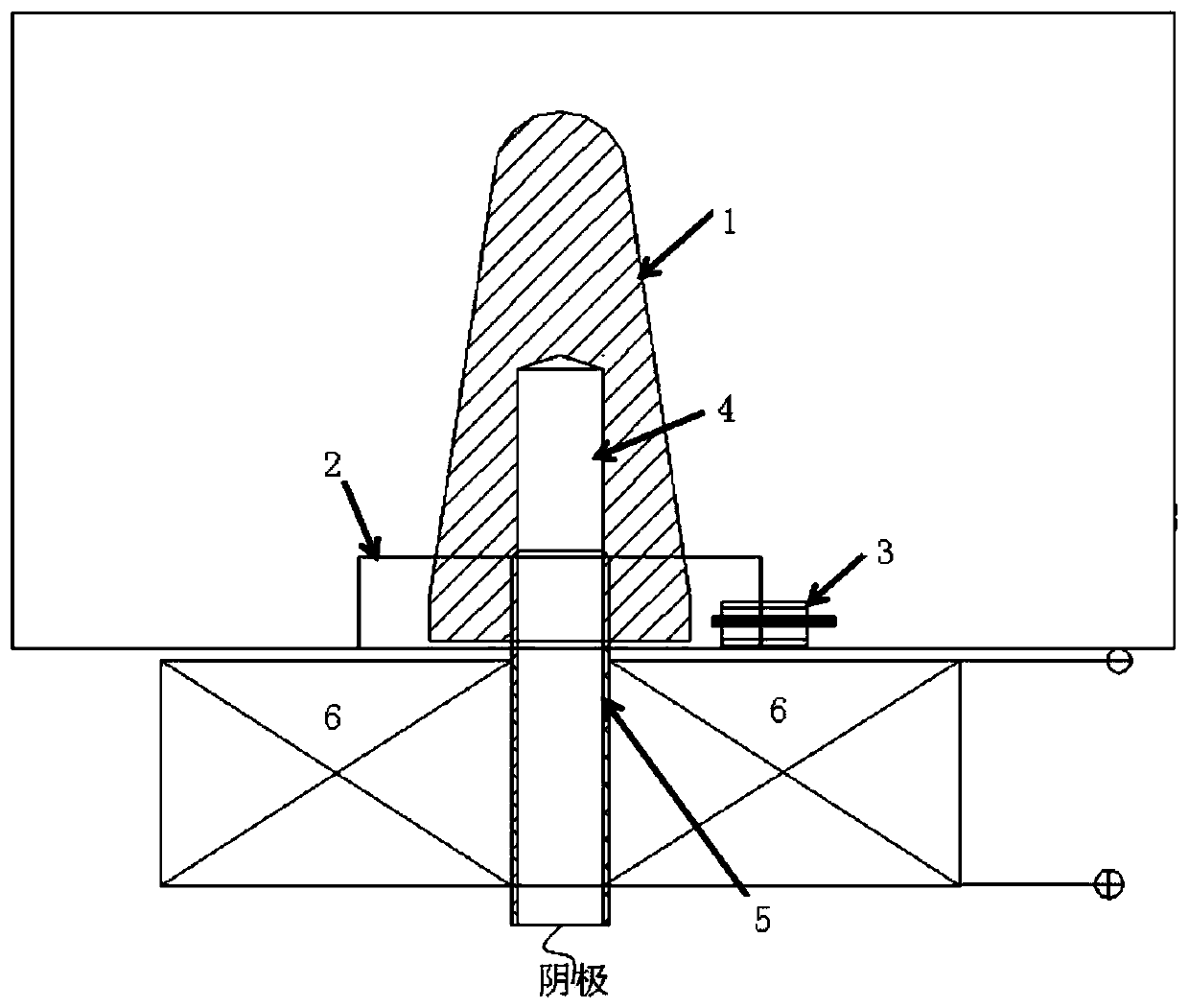

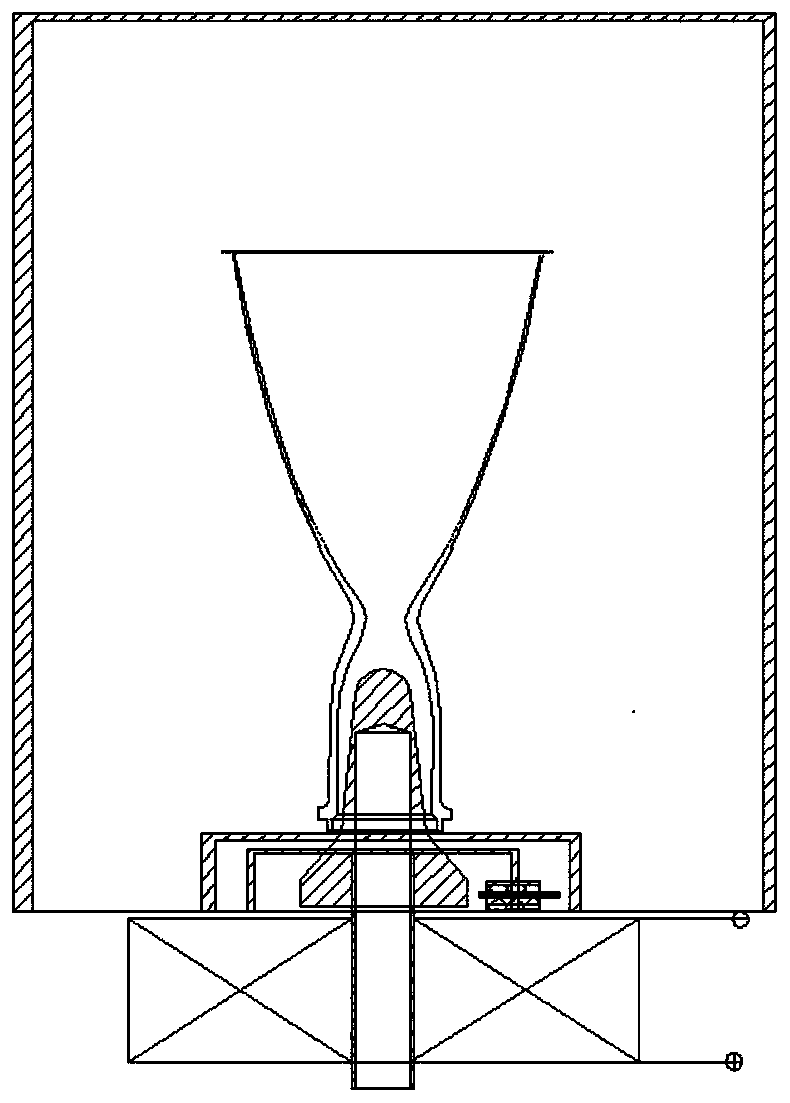

[0052] (1) if image 3 Shown is the schematic diagram of the arc source of the arc deposition cathode on the inner surface of the engine nozzle of the present invention from the straight line to the throat position; 2. The arc spot movement on the surface of the cathode target is controlled by an electromagnetic field, and the current waveform adopts a triangular wave with an amplitude of 0.2-15A and a frequency of 1-5Hz. The distance and height of the arc spot moving on the target surface can be realized by adjusting the amplitude of the current, and the speed and etching time of the arc spot moving up and down on the cathode target surface can be controlled by controlling the frequency of current change. 3. The cathode target is designed as a hollow nozzle imitating cylindrical conical targe...

Embodiment 1

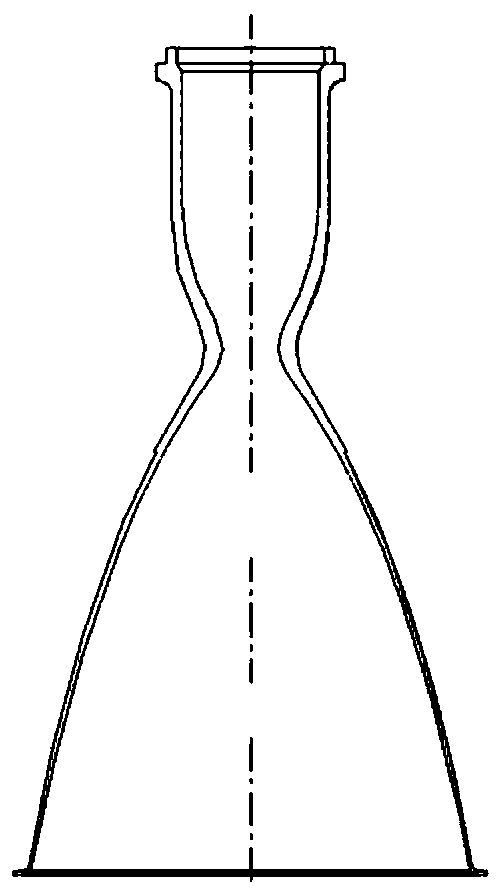

[0064] Such as figure 1 shown, in order to manufacture an engine nozzle with a size of ( is the minimum inner diameter of the engine nozzle, and 100mm is the total length of the engine nozzle) as an example, the Mo-W alloy coating is deposited on the inner surface of the engine nozzle.

[0065] (a) Engine nozzle preparation: process the engine nozzle according to the drawing requirements of the engine nozzle Such as figure 1 , After the processing is completed, degrease and derust the inner and outer surfaces of the engine nozzle, mainly by pickling and acetone ultrasonic cleaning, and wait for the deposition of the coating after drying.

[0066] (b) Preparation of engine nozzle Mo-W alloy coating;

[0067] It uses the following steps to prepare a Mo-W alloy coating on the inner surface of the engine nozzle:

[0068] (1) Process two Mo-W alloy (Mo:W=80:20% by weight) cathode targets 1 according to the drawing size, such as figure 2 , are the Mo-W alloy target used fr...

Embodiment 2

[0079] To manufacture an engine nozzle size of ( Be the minimum inner diameter of the engine nozzle, 200mm is the total length of the engine nozzle) as an example, the iridium coating is deposited on the inner surface of the engine rhenium nozzle, and the specific implementation of the method of the present invention is described.

[0080] (a) Engine rhenium nozzle preparation: process the engine nozzle according to the drawing requirements of the engine rhenium nozzle Such as figure 1 After the processing is completed, degrease and derust the inner and outer surfaces of the rhenium nozzle of the engine, mainly by pickling and ultrasonic cleaning with acetone, and wait for the coating to be deposited after drying.

[0081] (b) Preparation of iridium coating for engine rhenium nozzle:

[0082] It uses the following steps to prepare an iridium coating on the inner surface of the engine nozzle:

[0083] (1) Process the profiling iridium (99.98at.%) cathode internal target ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com