Method, apparatus, system and method for washing and disinfecting wet foam fluid

A technology of foam fluid and washing liquid, applied in the control device of washing machine, washing device, other washing machines, etc., can solve the problem of reducing washing effect, etc., and achieve the effect of good penetration, enlarged contact area, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

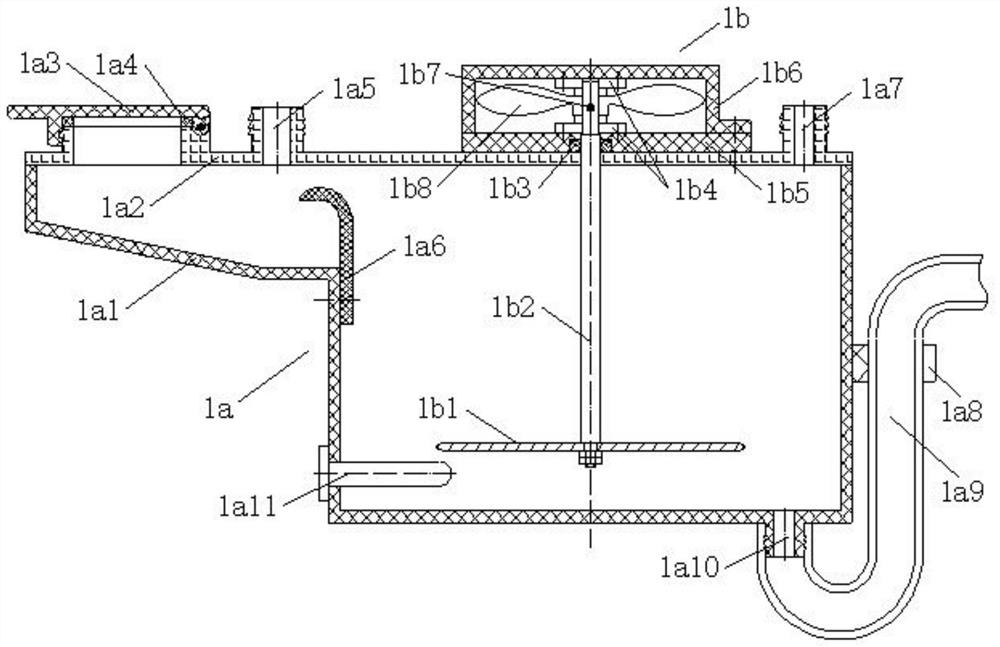

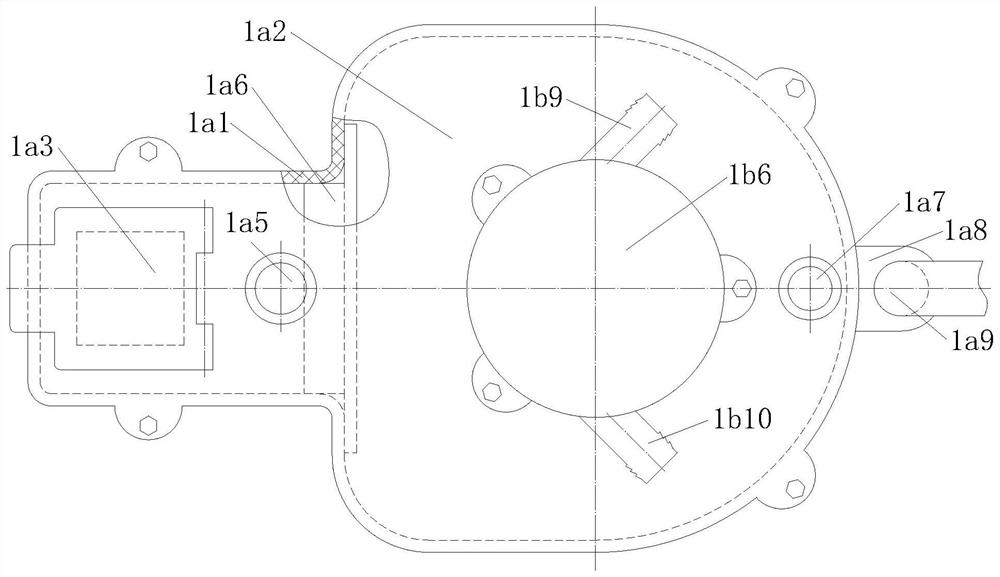

[0051] This embodiment discloses a device for preparing wet foam fluid, refer to Figures 1 to 5 As shown, a mixer dissolver 1 and a wet foam generator 2 are included. The wet foam generator 2 includes a microcellular foam generator 2a having a closed cavity. The microcellular foam generator 2a is provided with a circular fence plate 2a3 which can block the cavity up and down. Thin strip-shaped through grooves are densely distributed on the fence circular plate 2a3. A microporous cylindrical flange 2a5 is symmetrically inserted on the microporous foam generator 2a. The microporous cylindrical flange 2a5 is located below the fence circular plate 2a3. The microporous cylindrical flange 2a5 is densely covered with fine through holes in the cylindrical section and the end portion located in the cavity of the microporous foam generator 2a. The upper and lower ends of the microcellular foam generator 2a are respectively provided with a liquid inlet 2a1 and a fluid outlet 2a7. T...

Embodiment 2

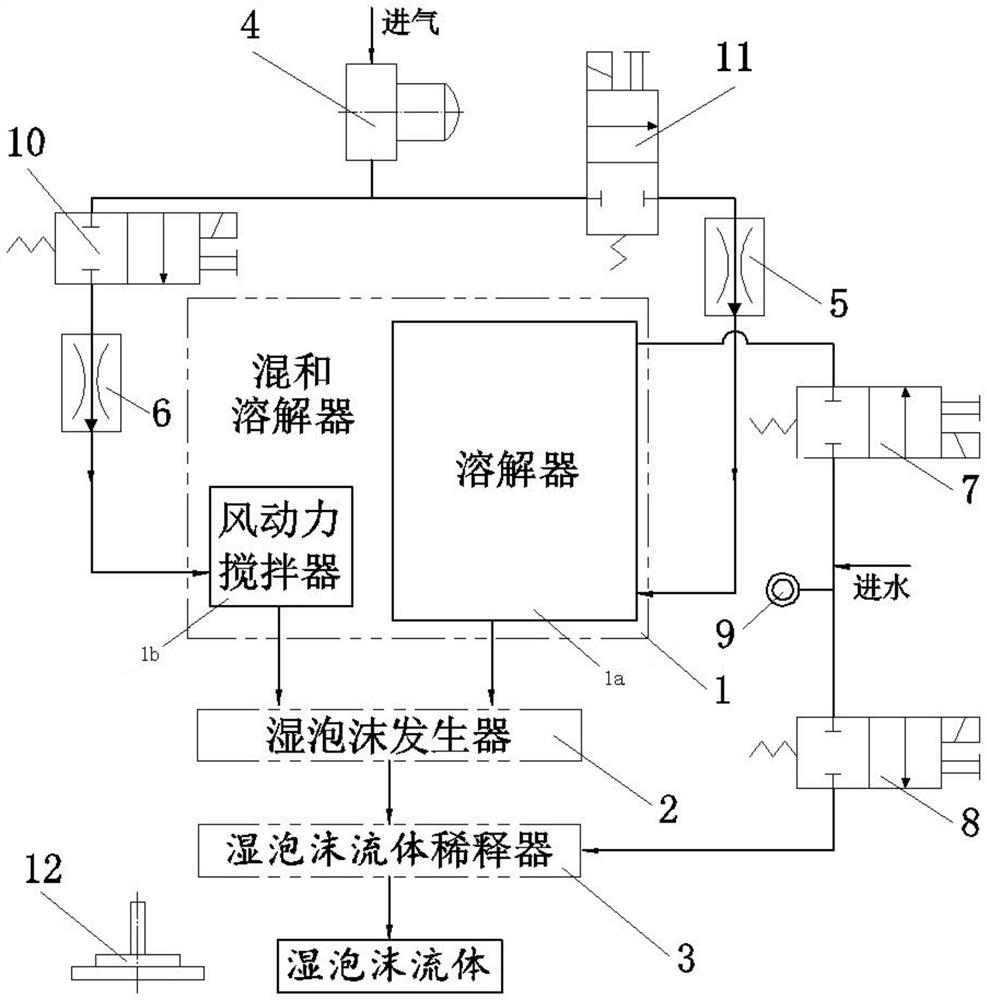

[0063] This embodiment discloses a system for preparing wet foam fluid, refer to Figures 1 to 5 As shown, it includes the mixing dissolver 1 and the wet foam generator 2 in Example 1, and also includes the wet foam fluid diluter 3, the gas booster pump 4, the gas throttle valve one 5, the gas throttle valve two 6, the water On-off valve 7, water inlet valve 8, water pressure sensor 9, large-flow gas on-off valve 10 and low-flow gas on-off valve 11.

[0064] The diameter of the water switch valve 7 is smaller than that of the water inlet valve 8 . The inlets of the water switch valve 7 and the water inlet valve 8 are connected in parallel with the water source. The outlet of the water switch valve 7 communicates with the mixing dissolver 1 . The first gas throttle valve 5 and the second gas throttle valve 6 are connected in parallel to the output end of the gas booster pump 4 . The outlet of the second gas throttle valve 6 is communicated with the airflow inlet 1b9 of the a...

Embodiment 3

[0071] The present embodiment discloses a method for preparing a wet foam fluid, which includes the following steps: S1, at least according to the number and type of laundry to be washed, determining the amount of washing water A in the washing tub during the washing process; S2, at least according to the amount of washing water and dirt Determine the amount of detergent b, and the amount of water a required to dissolve the amount of detergent b into a high-concentration washing solution; S3, first put the amount of detergent b in the container, and then make the amount of water directly Enter into the container to shock and mix to form a high-concentration washing liquid; S4, pass the high-concentration washing liquid and compressed air into the wet foam generator at the same time through different inlets to prepare a wet foam fluid; The foam fluid and the water not greater than A-a are simultaneously introduced into the wet foam fluid diluter through different inlets, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com