V-H composite bearing capacity model test loading device and method

A technology for loading equipment and model testing, which is applied in the testing of infrastructure, construction, infrastructure engineering, etc. to achieve high repeatability, manpower saving, and flexible application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

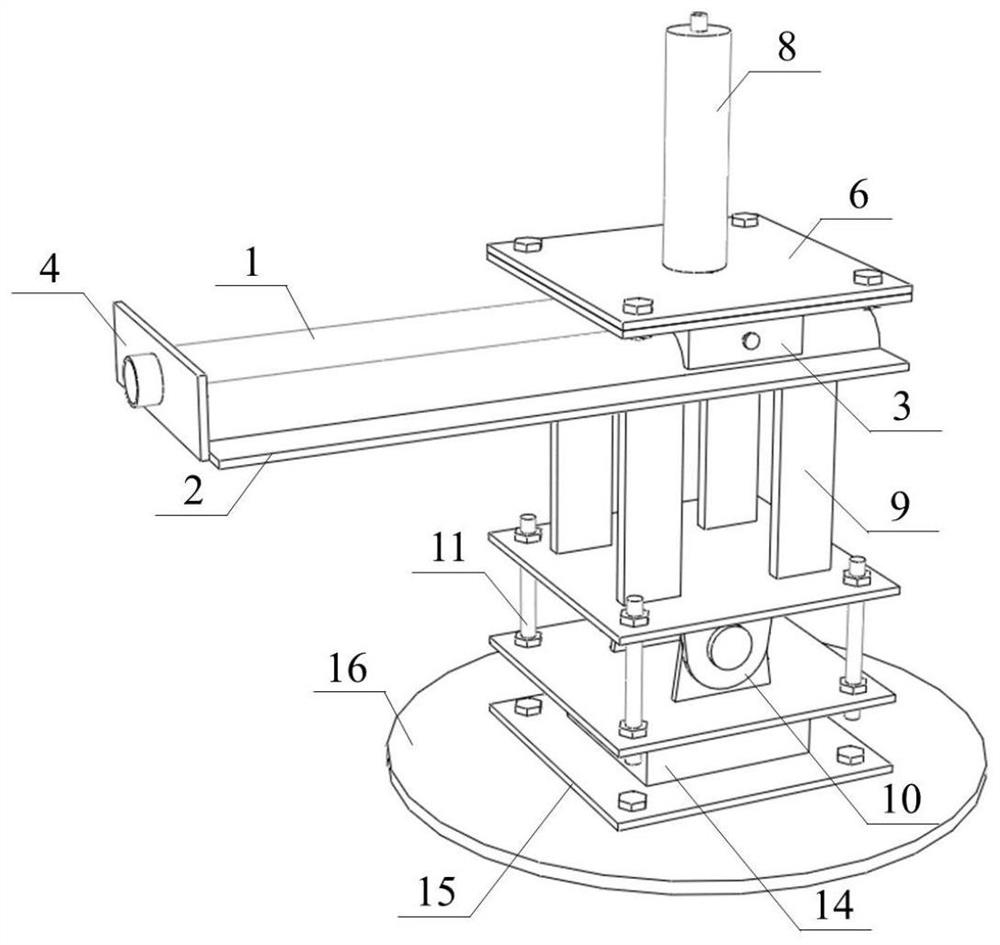

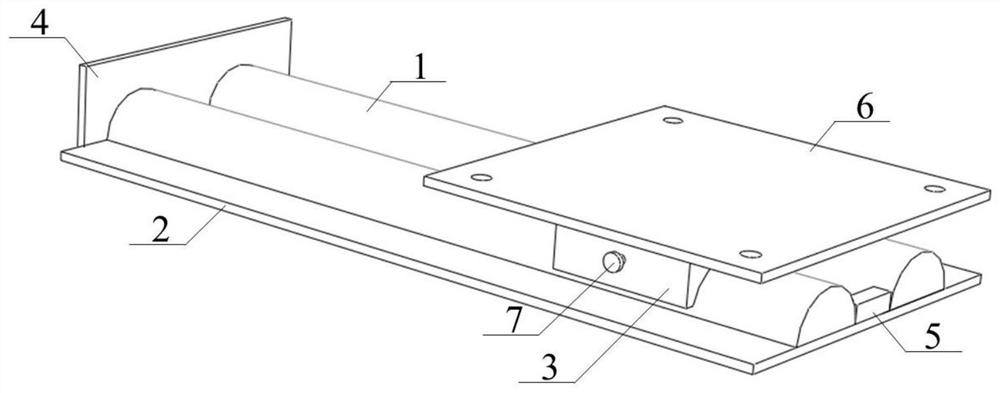

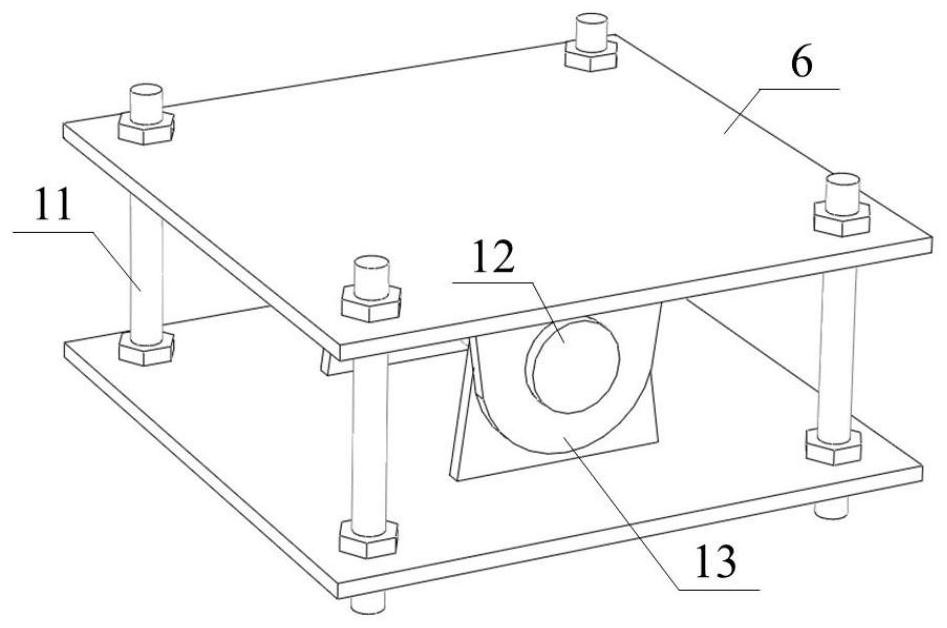

[0056] Such as Figure 1 to Figure 3 As shown, a V-H composite bearing capacity model test loading device includes a horizontal loading system, a vertical loading system, a conversion system, a sensor 14 and a base plate 15;

[0057] The horizontal loading system includes a slide rail 1, a slide rail plate 2, a slider 3, a horizontal connector 4 and a limit block 5; two slide rails 1 are fixed on the slide rail plate 2 in parallel; each slide rail 1 The slider 3 with locking function is set on the top, and the slider 3 is fixed on the slide rail 1 by the pin 7 to prevent sliding during vertical loading; the slider 3 can slide smoothly on the slide rail 1 by loosening the pin 7 , in order to apply horizontal loads; the top of the slider 3 is welded with a loading plate 6 for connection with the vertical loading system; one end of the slide rail 1 is welded with a horizontal connector 4 for connecting horizontal loading equipment, and the horizontal connector 4 The bottom of th...

Embodiment 2

[0075] When carrying out the vertical loading test: (1) firstly connect the assembled V-H composite bearing capacity model test loading equipment to the foundation 16 roof bolts through the bottom plate 15; (2) connect the loading rod 8 and the vertical loading motor; (3) Ensure that the slide rail plate 2 is flush with the end of each loading plate 6, lock the slider 3, level the fixed screw 11, connect the sensor 14 and the data acquisition instrument, and carry out vertical loading.

Embodiment 3

[0077] When carrying out the horizontal loading test: (1) firstly connect the assembled V-H composite bearing capacity model test loading equipment with the foundation 16 roof bolts through the bottom plate 15; (2) connect the loading rod 8 and the vertical loading motor, this operation is In order to play the role of erecting and fixing loading equipment when loading horizontally; (3) the horizontal connector 4 of the loading equipment is connected to the horizontal loading motor; (4) ensuring that the end of the slide rail plate 2 is flush with each loading plate 6, Loosen the slider 3, disassemble the fixing screw 11, connect the sensor 14 and the data acquisition instrument, and carry out horizontal loading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com