Intelligent photovoltaic module structure and whole roof laying method

A photovoltaic module and photovoltaic module technology, applied in the direction of roof, photovoltaic power generation, roof covering layer, etc., can solve the problems of affecting the appearance, scattered photovoltaic module layout, affecting the power generation capacity of the power station, etc., and achieve the effect of reliable structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

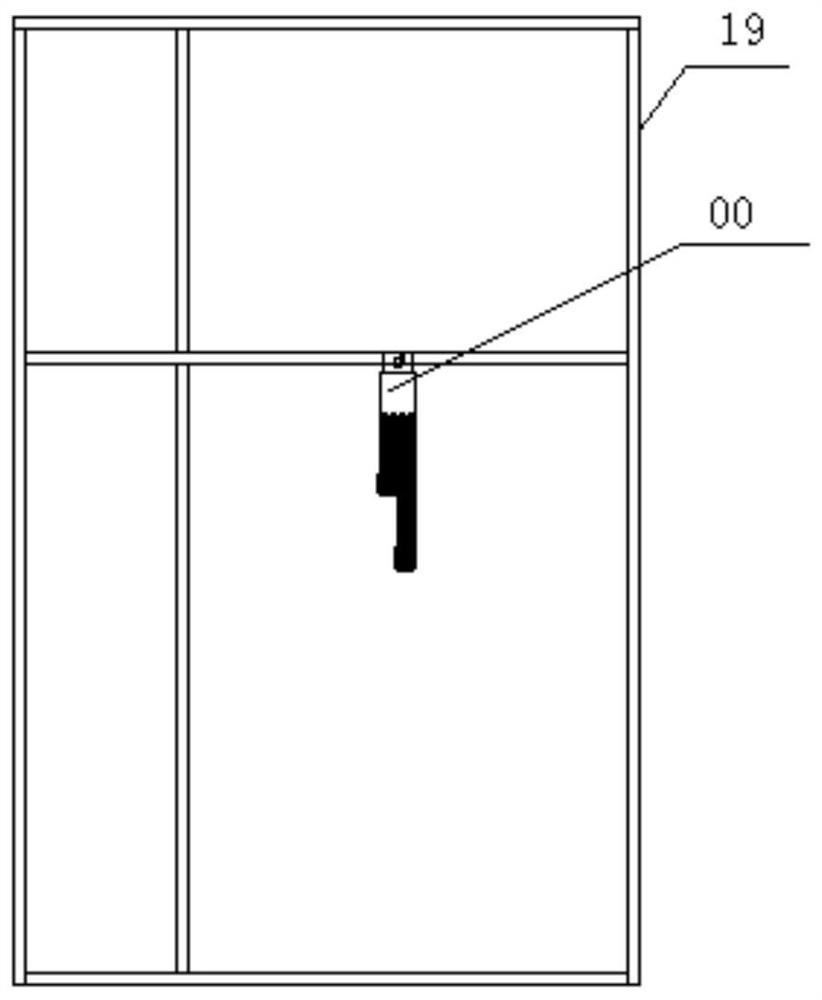

[0027] The present invention will be described in detail below with reference to the accompanying drawings. The smart photovoltaic optimizer 00 of the present invention has an existing structure and can be purchased directly.

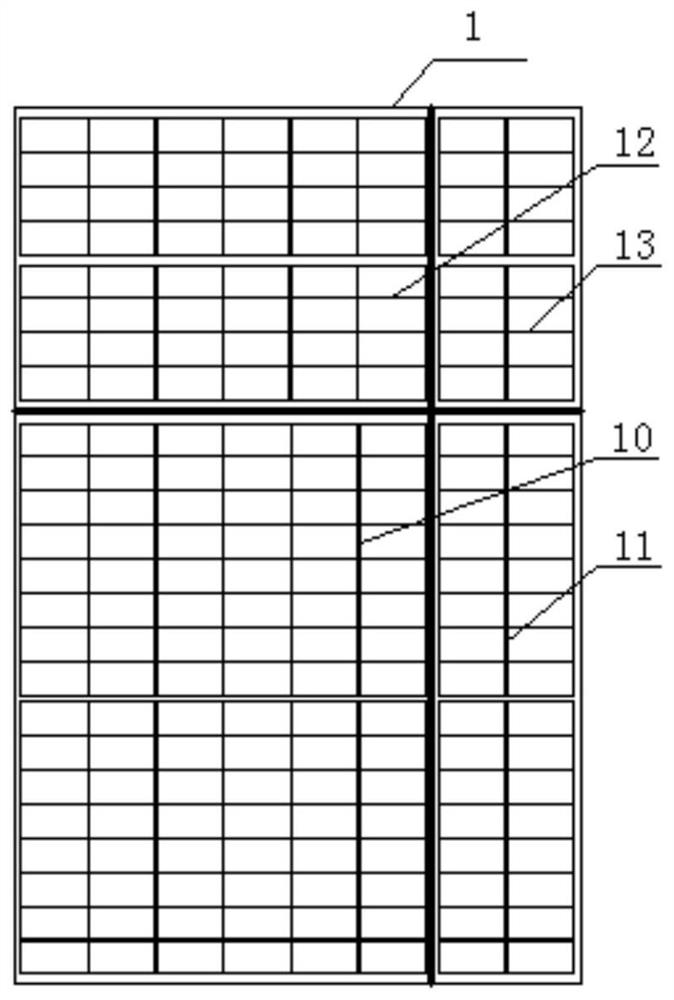

[0028] Such as Figure 2a , Figure 2b As shown, a smart photovoltaic module structure includes several photovoltaic components, a module integration frame 19 and an intelligent photovoltaic optimizer 00, which is characterized in that: the plurality of photovoltaic components are arranged according to the grid shape on the module integration frame 19 One-to-one correspondence, and fixed on the module integration frame 19 by structural glue; the smart photovoltaic optimizer 00 is fixed on the module integration frame 19, and several photovoltaic modules are connected in series with the smart photovoltaic optimizer 00, and the smart photovoltaic optimizer 00 With PV module monitoring, safe shutdown and power optimization functions. The shape of the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com