Inclined layered solid ore deposit mining method

A mining method and technology of inclined layer, which are applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of difficult roof management, low degree of mechanization, backward ore transportation technology, etc. The effect of advancing speed and reducing health and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment A kind of mining method of inclined layered solid deposit

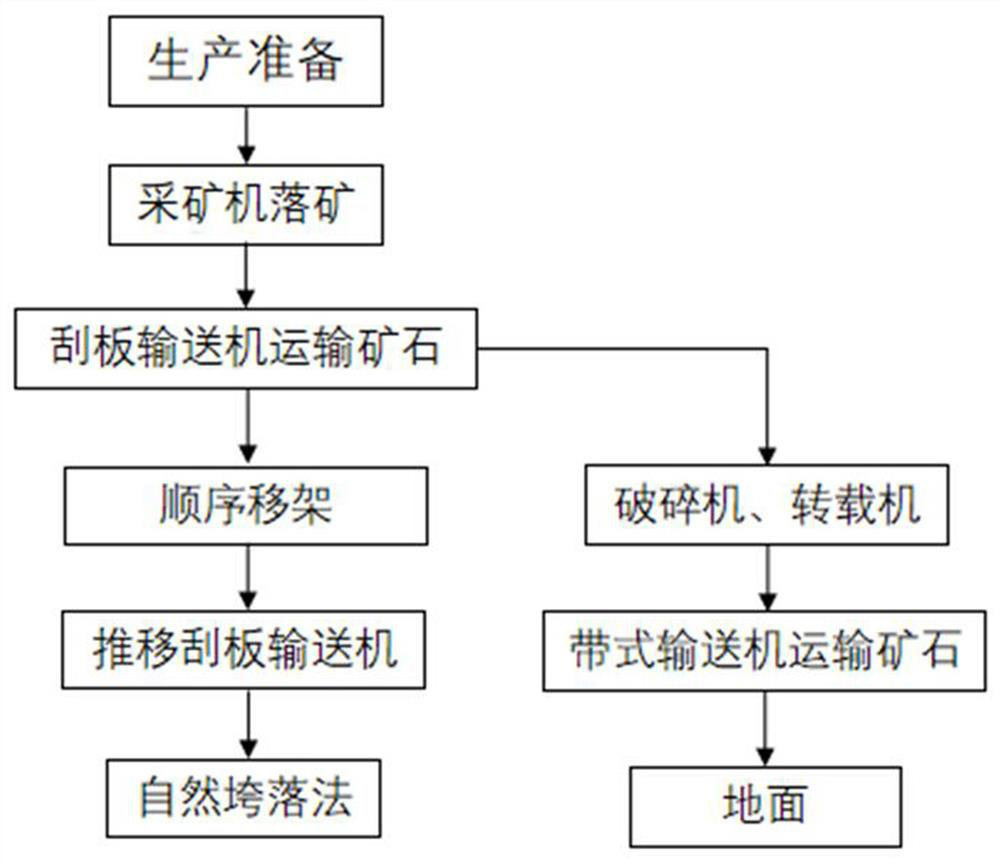

[0046] Inclined layered solid ore deposit mining method, see the technical process figure 1 , including the following steps, in order:

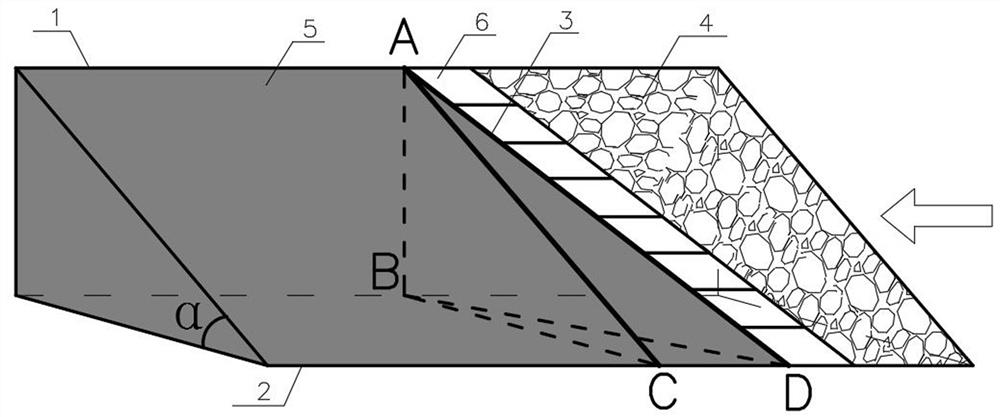

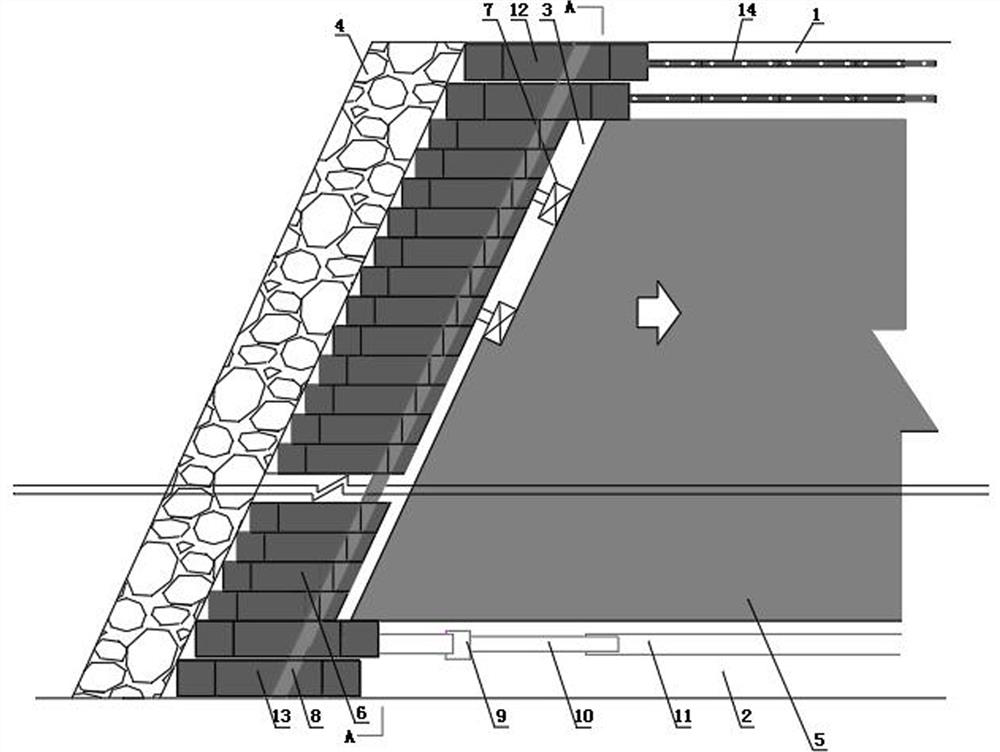

[0047] 1) Working surface layout

[0048] Select an inclined layered non-coal solid deposit with a dip angle of 35°-65° and a thickness of 0.8-5m (the ore body of the Zhongli Phosphate Deposit in Shimen County, Hunan Province is layered, with an average thickness of 4.5m and a dip angle of about 55° ),refer to figure 2 and image 3 As shown in , with the positional relationship between the two boundaries of the inclined ore body 5 parallel to the trend of the inclined ore body 5 and being close to the ground and away from the ground being left and right, along the trend of the inclined ore body 5, the inclined ore body 5 Divided into ore blocks, the length of the ore block is 140-160m, the width is the full thickness of the inclined ore body 5, and the height i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com