Fully-mechanized excavation roadway quick excavation process based on duplex multi-group self-moving walking type temporary support

A technology of temporary support and fully mechanized roadway, which is applied in the direction of mine roof supports, tunnels, mining equipment, etc., can solve the problems of low degree of automation and imperfect safety guarantee, reduce labor intensity, improve automation degree and efficiency, and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

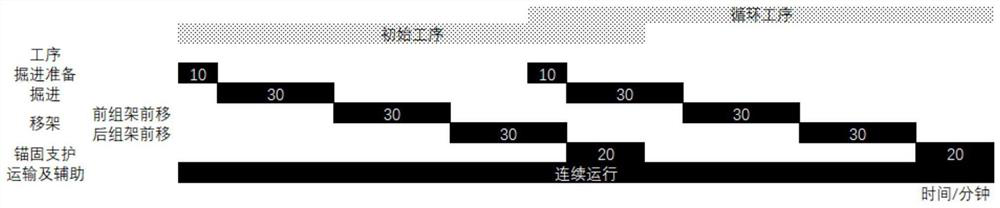

[0031] In order to further explain in detail the technical scheme adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the rapid excavation process of fully mechanized roadway based on the double-connected multi-group self-moving stepping temporary support proposed by the present invention will be described below in conjunction with the accompanying drawings. And its process is described in detail as follows.

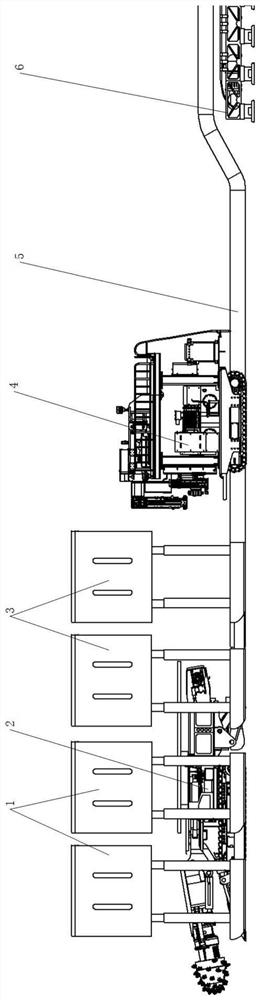

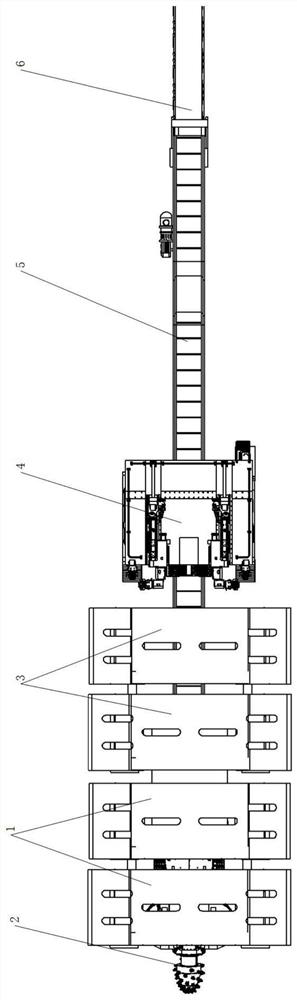

[0032] Such as figure 1 , figure 2 Shown is the equipment layout of the rapid excavation process of fully mechanized roadway based on double-connected multi-group self-moving stepping temporary supports. ), double-connected multi-group self-moving step-type temporary supports (1, 3), reloader (5) and transporter (6) are jointly completed. Its layout mode is that the intelligent cantilever roadheader (2) is arranged under the double-connected multi-group self-moving step-type temporary supports (1, 3), behin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com