A control method of dynamic characteristics of on-off valve based on compound pwm

A technology of dynamic characteristics and switching valves, applied in the direction of magnetic objects, electromagnets with armatures, electrical components, etc., can solve problems such as current hysteresis and movement hysteresis, achieve high reliability, increase current maintenance phase, and shorten time ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further elaborated and described below in combination with specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0068] 1. Hardware system

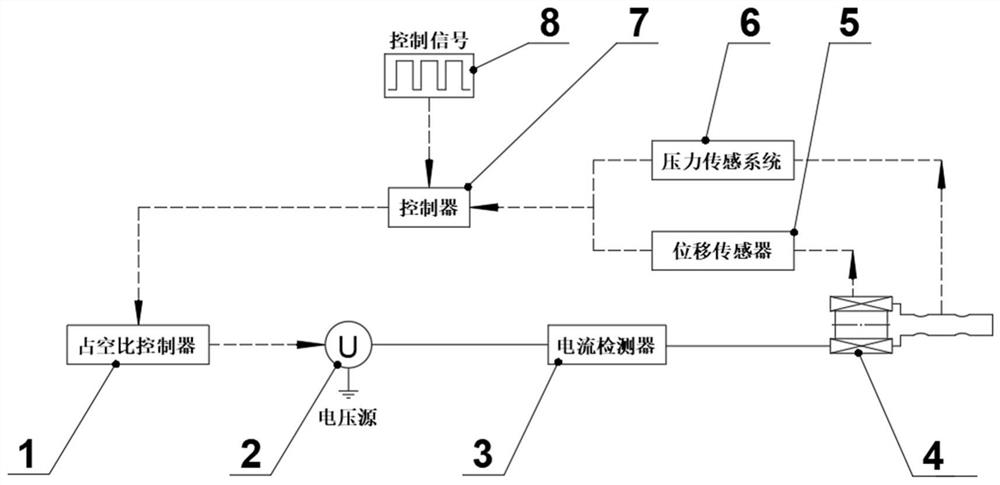

[0069] Such as figure 1 As shown, the composition of the optional hardware system of the present invention may include a duty ratio controller 1, a voltage source 2, a current detector 3, a switching valve 4, a pressure sensing system 6, a displacement sensor 5, and a controller 7;

[0070] The coil of the switching valve is connected to the voltage source 2 through the current detector 3, the controller is connected to the duty cycle controller, the duty cycle controller is connected to the voltage source to output a high-frequency square wave signal to the voltage source, and the pressure sensing system 6 is connected to the voltage source. The working ports of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com