Steam generating device

A technology of steam generating device and liquid level position, which is applied in the direction of steam generation, steam generation method, control system, etc., and can solve the problems of safety and hidden dangers of isopropanol vapor, difficulty in controlling the concentration and stability of isopropanol vapor, etc. Achieve the effect of stabilizing the process and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

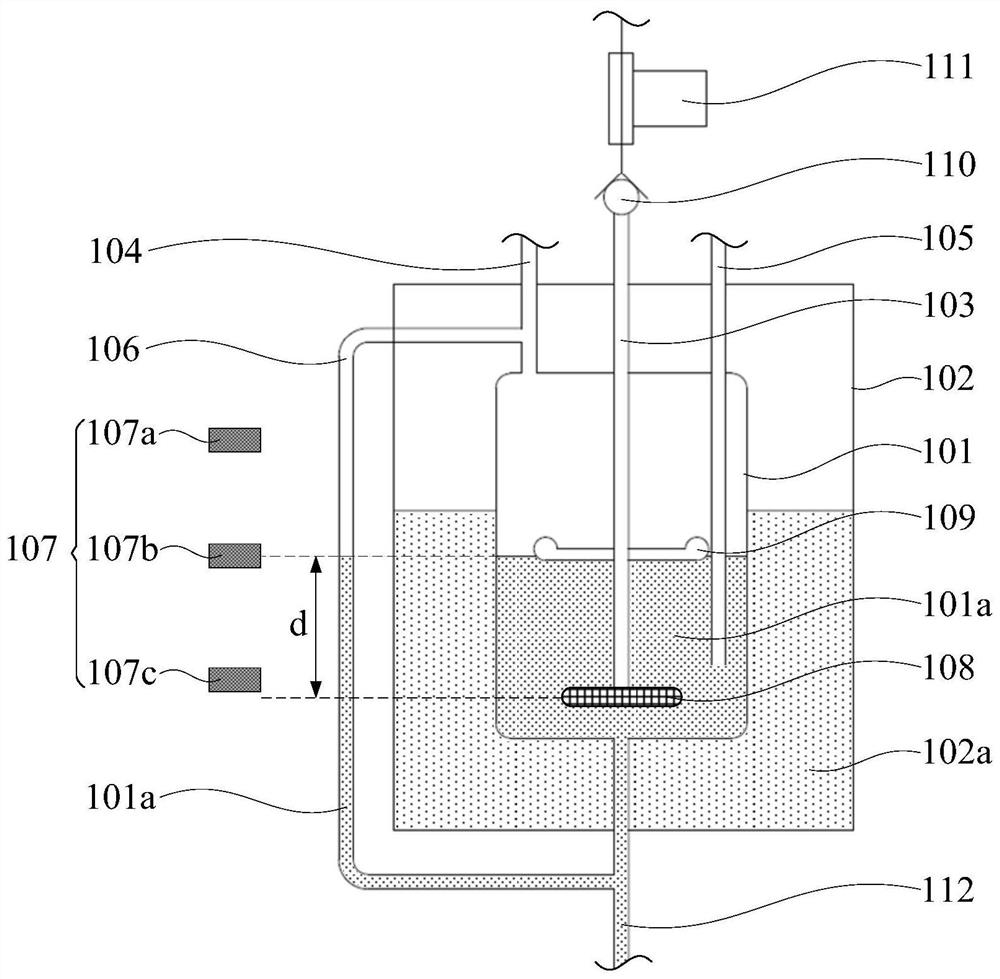

[0045] see figure 1 , the present embodiment provides a steam generating device, comprising:

[0046] A liquid medicine storage tank 101, which is used to accommodate the liquid medicine 101a;

[0047] Medium heat preservation tank 102, which is used to accommodate heat preservation medium 102a with a set temperature; said liquid medicine storage tank 101 is placed in said medium heat preservation tank 102, and said liquid medicine storage tank 101 makes The medicinal liquid 101a maintains a set temperature;

[0048] A carrier gas supply module, which includes a carrier gas source for providing carrier gas and a carrier gas supply pipeline 103; the carrier gas supply pipeline 103 includes an inlet end and an outlet end, and the inlet end is connected to the carrier gas source, The gas outlet end extends into the liquid medicine 101a; the carrier gas supply module also includes a carrier gas distribution unit installed at the gas outlet end of the carrier gas supply pipeline ...

Embodiment 2

[0063] This embodiment provides a steam generating device. Compared with Embodiment 1, the difference of this embodiment is that the steam generating device includes a plurality of carrier gas distribution units, that is, a plurality of nano gas disc stones. The plurality of nano-gas disk stones can all keep the same definite distance from the liquid liquid surface, be evenly distributed in the horizontal plane at the same height in the liquid liquid storage tank, and be connected to the same carrier gas supply pipeline. Optionally, there are six nano gas disc stones, and the connecting lines of adjacent individuals form a regular hexagon, so as to be evenly distributed in the horizontal plane where they are located. The quantity of the nano gas rocks can be adjusted according to the size and shape of the nano gas rocks. By arranging a plurality of uniformly distributed nano gas disc stones, the steam generating device provided in this embodiment improves the carrier gas suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com