Experimental device for testing cement hydration heat

An experimental device, cement hydration technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of high cost of use, influence on the accuracy of experimental results, and insignificant changes in sample temperature, and achieve easy operation and test The results are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings, so that those skilled in the art can understand. At the same time, the present invention is not limited to the scope of specific embodiments. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all included in the protection.

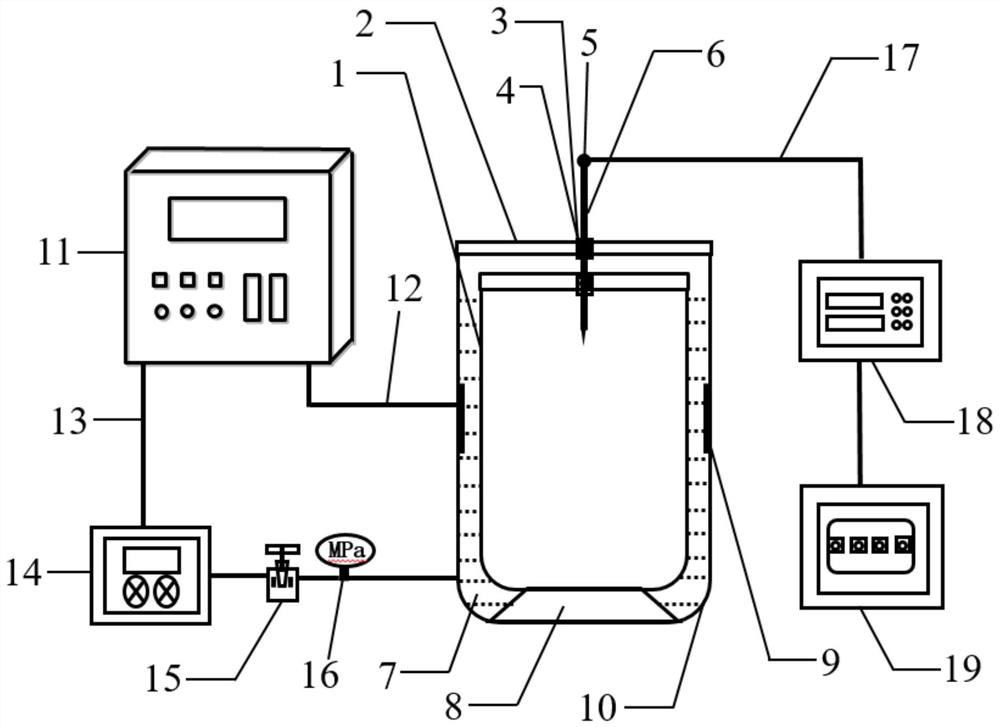

[0025] see figure 1 .

[0026] An experimental device for testing the heat of hydration of cement, comprising a thermal insulation container 10, a heating plate 9, a closed kettle cover 2, a sample cylinder 1, a temperature sensor 6, a control panel 11, a booster pump 14, a modulus converter 18 and Computer 19, the inner wall of the heat-retaining container 10 is provided with a heating sheet 9, the top is a closed kettle cover 2, and the bottom is fixed with a support frame 8 for the sample cylinder 1, between the heat-retaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com