Application of planar carrier plate in wafer bearing

A wafer carrying and wafer technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as the inability to meet the high temperature process of wafers, the poor high temperature resistance of adhesives, and the inability to stabilize wafers. , to achieve the effect of overcoming the temperature limit, simple production, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An application of a plane carrier plate in wafer carrying, characterized in that, the surface of the plane carrier plate is provided with a number of air suction holes for adsorbing wafers, and the application method specifically includes the following steps:

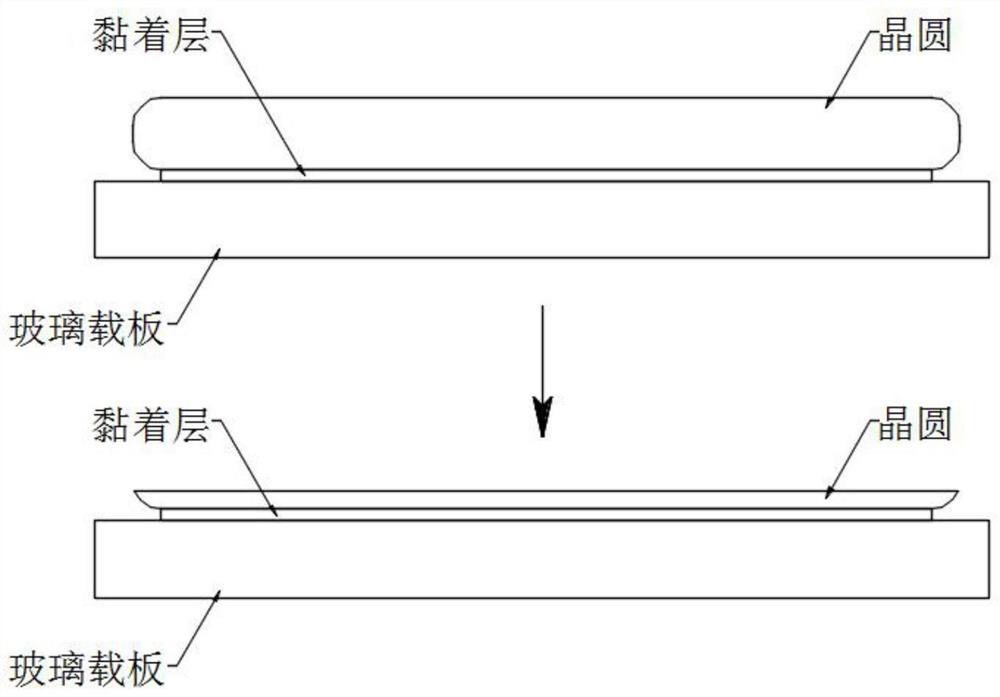

[0029] S1. On the front side of the wafer where the ILD process and the contact hole opening are completed, the glass carrier is bonded with an adhesive, and then the back side of the wafer is thinned by grinding / etching, and the ion implantation process on the back side of the wafer is completed;

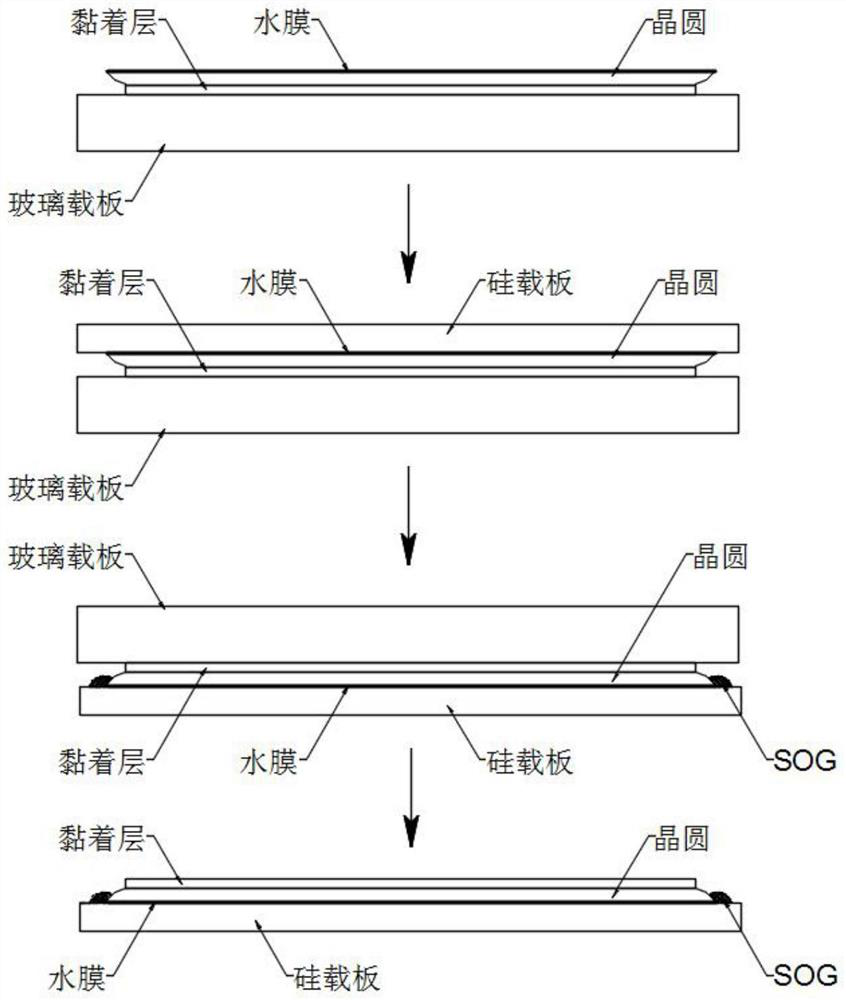

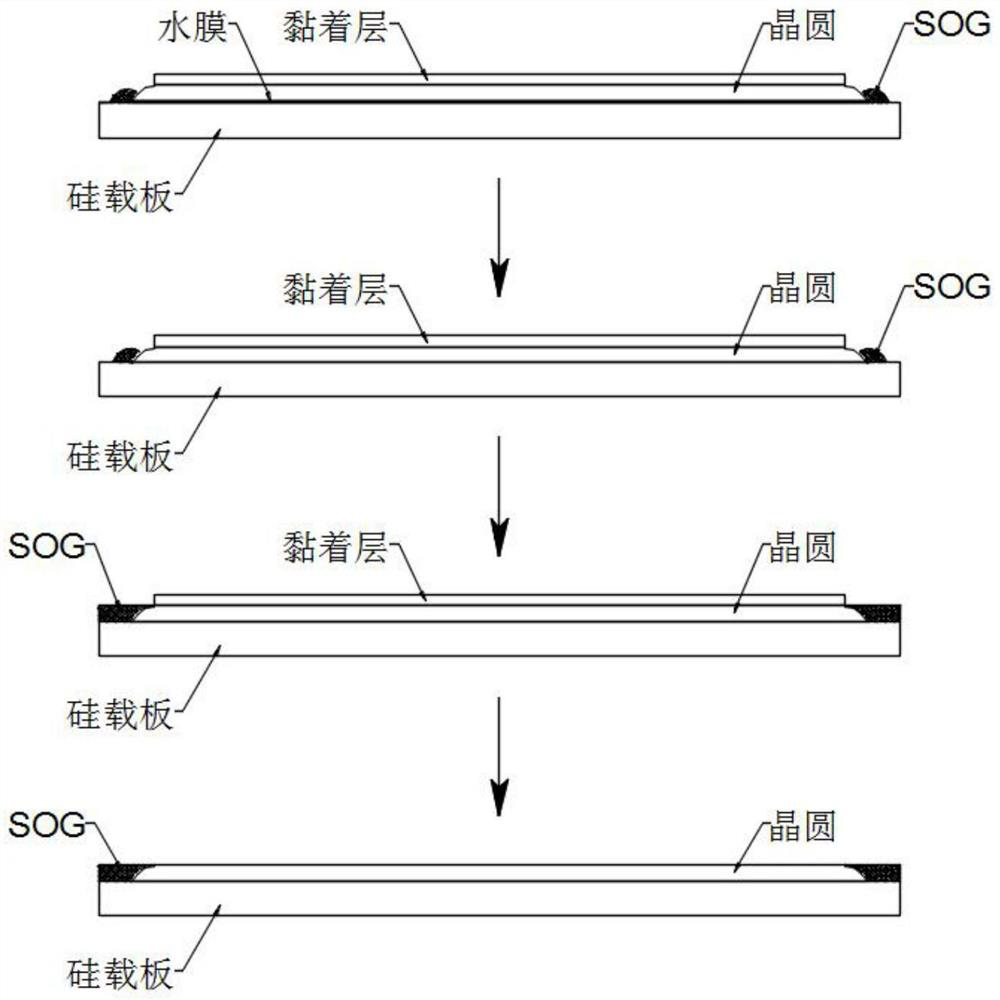

[0030] S2. Spray deionized water on the back of the wafer to form a water film with a uniform thickness, and then attach a silicon carrier to the back of the wafer. With the help of the gravitational force between water molecules and the external atmospheric pressure, the silicon carrier is connected to the wafer. Adsorb, then turn the glass carrier plate, the wafer and the silicon carrier plate as a whole, apply SOG t...

Embodiment 2

[0035] An application of a plane carrier plate in wafer carrying, characterized in that, the surface of the plane carrier plate is provided with a number of air suction holes for adsorbing wafers, and the application method specifically includes the following steps:

[0036] S1. On the front side of the wafer where the ILD process and the contact hole opening are completed, the glass carrier is bonded with an adhesive, and then the back side of the wafer is thinned by grinding / etching, and the particle implantation process on the back side of the wafer is completed;

[0037] S2. Spray deionized water on the back of the wafer to form a water film with a uniform thickness, and then attach a silicon carrier to the back of the wafer. With the help of the gravitational force between water molecules and the external atmospheric pressure, the silicon carrier is connected to the wafer. Adsorb, then turn the glass carrier plate, the wafer and the silicon carrier plate as a whole, apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com