Method and device for collecting rheological parameters of drilling fluid, storage medium and processor

A technology of rheological parameters and drilling fluids, which is applied in the field of obtaining rheological parameters of drilling fluids, can solve problems such as inaccurate measurement of rheological parameters, and achieve the effect of solving inaccurate measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

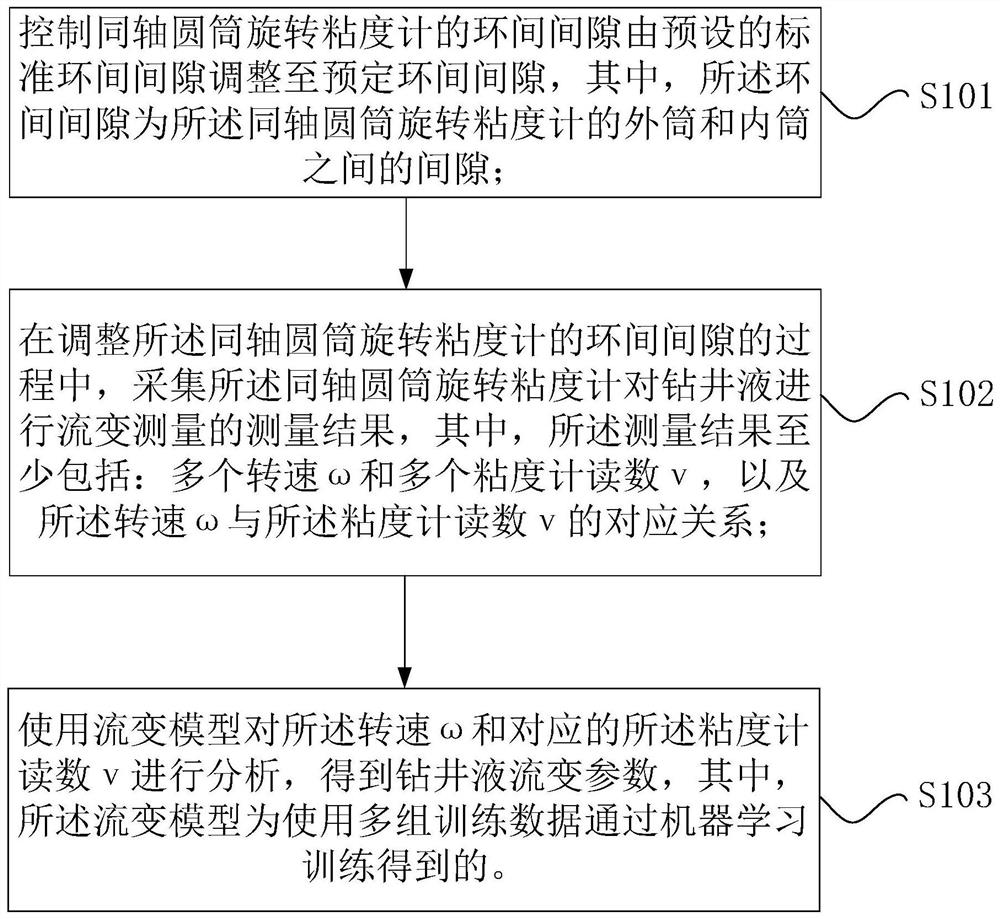

Method used

Image

Examples

Embodiment

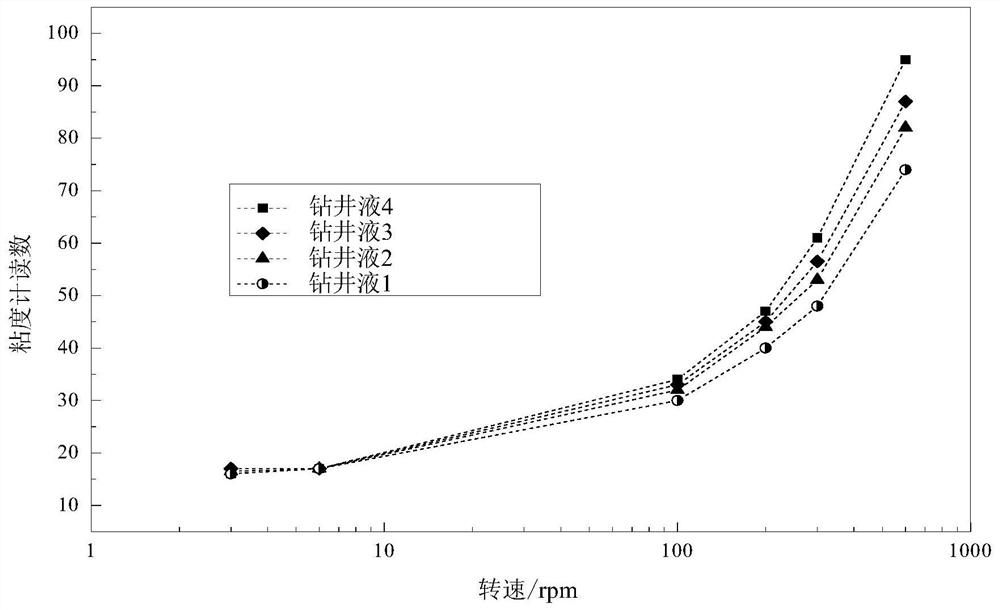

[0055] Drilling fluid includes plugging base slurry while drilling and plugging materials while drilling, wherein, plugging base slurry while drilling is composed of bentonite, potassium hydroxide, vinyl monomer multi-polymer, sulfonated lignite, sulfonated lignite resin, specific composition The fractions and their contents are shown in Table 1. After sieving, calcium carbonate particles of various sizes are mixed to form LPM-C, LPM-M and LPF-F three types of plugging materials while drilling with different particle sizes. The particle size distribution of LWD materials is shown in Table 2.

[0056] Table 1

[0057] component name function Content (wt.%) Bentonite Viscosifier & Fluid Loss Control Agent 4.0 KOH Inhibitors & pH Regulators 0.1 PAC-141 Coating agent 0.3 SMC Fluid loss control agent 1.0 SPNH Fluid loss control agent 3.0 SMP-2 Fluid loss control agent 2.0 XC flow regulator 0.2 KCl Shale in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com