Elevator head sheave lightweight design method based on a radial basis function proxy model

A technology of lightweight design and proxy model, applied in the field of lightweight design of hoist crown wheel based on radial basis function proxy model, can solve the problems of inability to determine the optimal result of the model, low design efficiency, and high development cost, and achieve shortening Cycle and development cost, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. The described specific examples are only for explaining the present invention, and are not intended to limit the present invention.

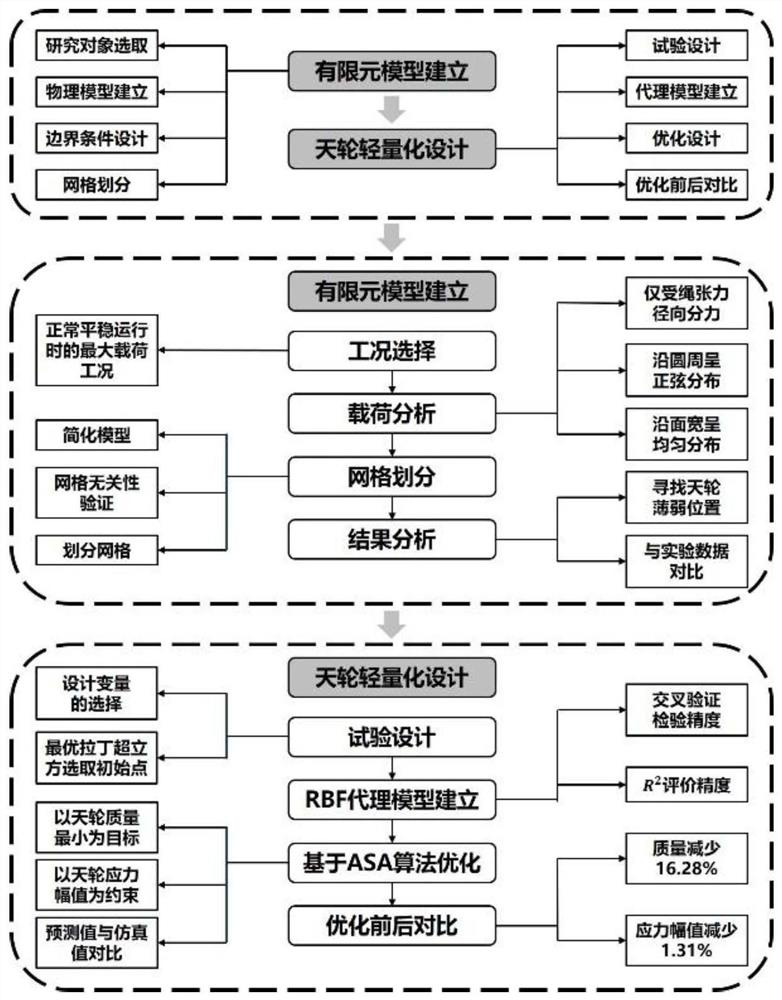

[0049] The invention provides a light-weight design method for the sky wheel of the hoist based on the radial basis function surrogate model. refer to figure 1 , figure 1 It is a research roadmap of a lightweight design method for hoist top wheels based on radial basis function surrogate model provided by the present invention, and its specific implementation steps are:

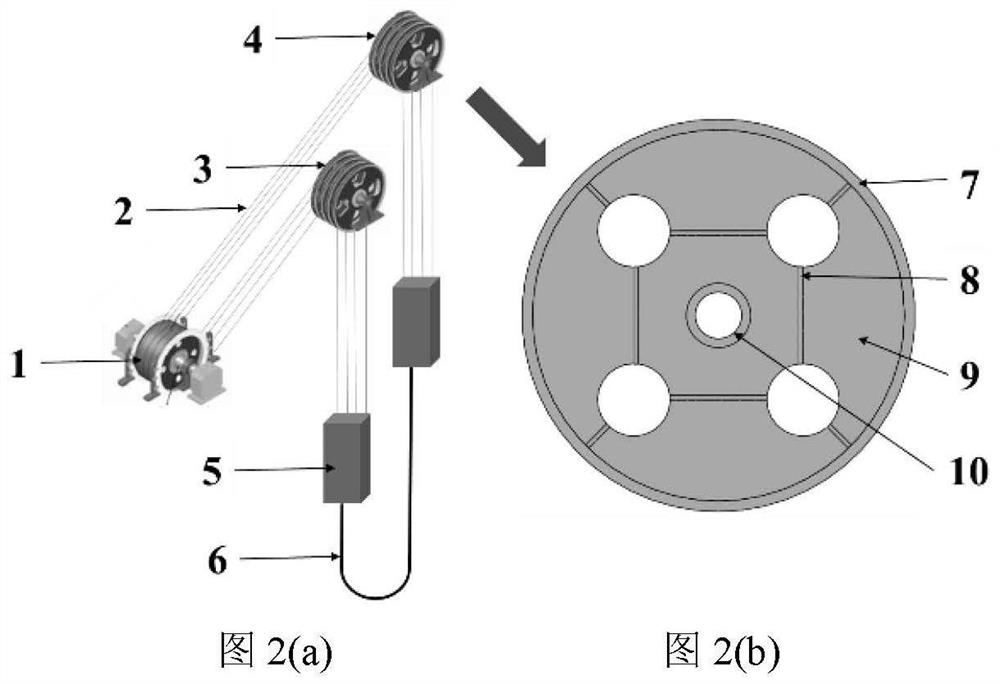

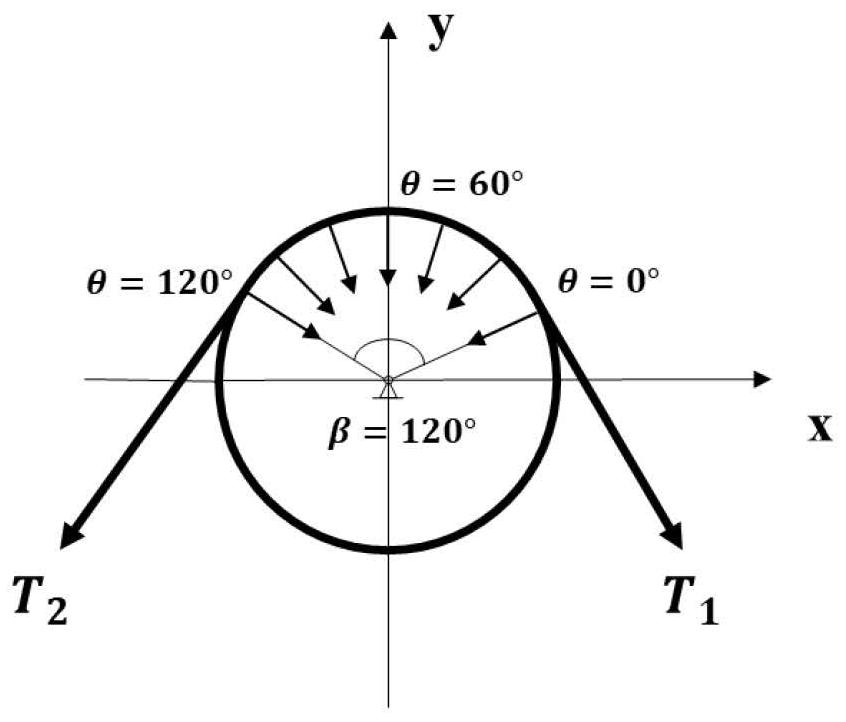

[0050] The first step is to take the sky wheel of a large mine hoist as the research object, as shown in Figure 2, where Figure 2(a) is a schematic diagram of a large mine hoist, Figure 2(b) is a three-dimensional model of the sky wheel, and 1 is the friction Wheel device, 2 is the wire rope, 3 is the lower sky ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com