A micro-led manufacturing method for improving sub-pixel luminescence balance

A manufacturing method and sub-pixel technology, applied in the field of displays, can solve problems such as poor display effect and uneven luminous brightness of sub-pixels, and achieve the effects of consistent sealant thickness, improved display effect, and balanced luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

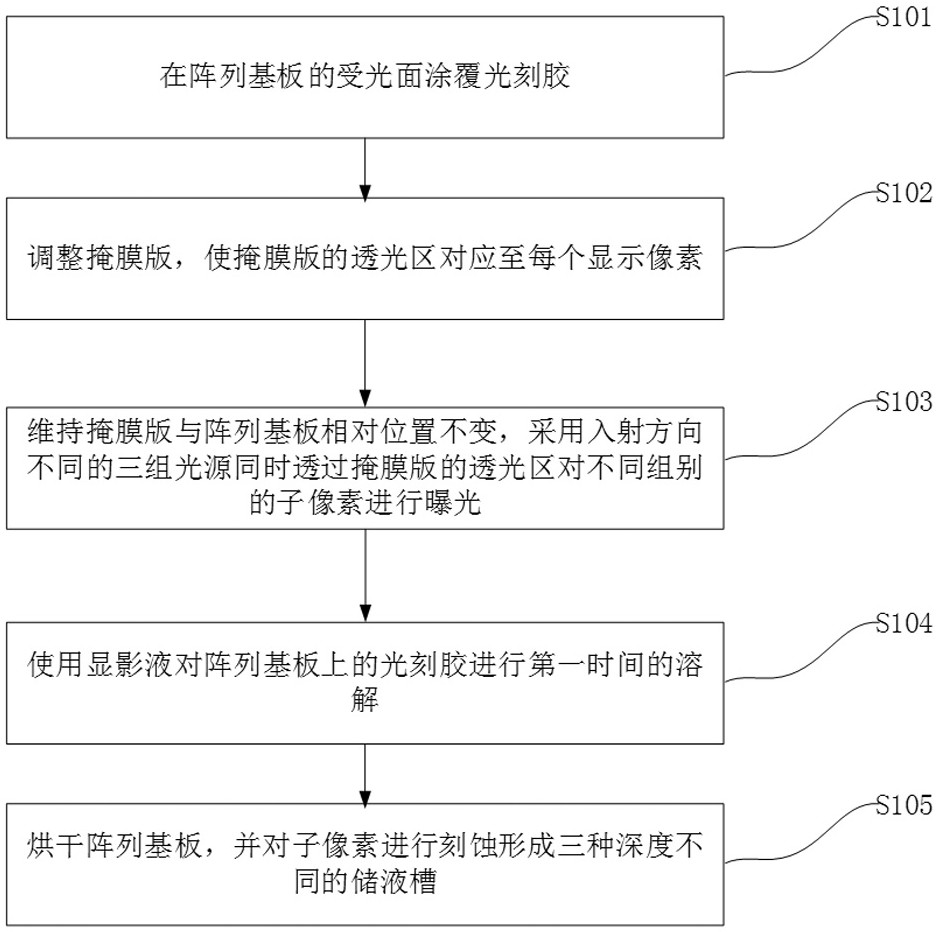

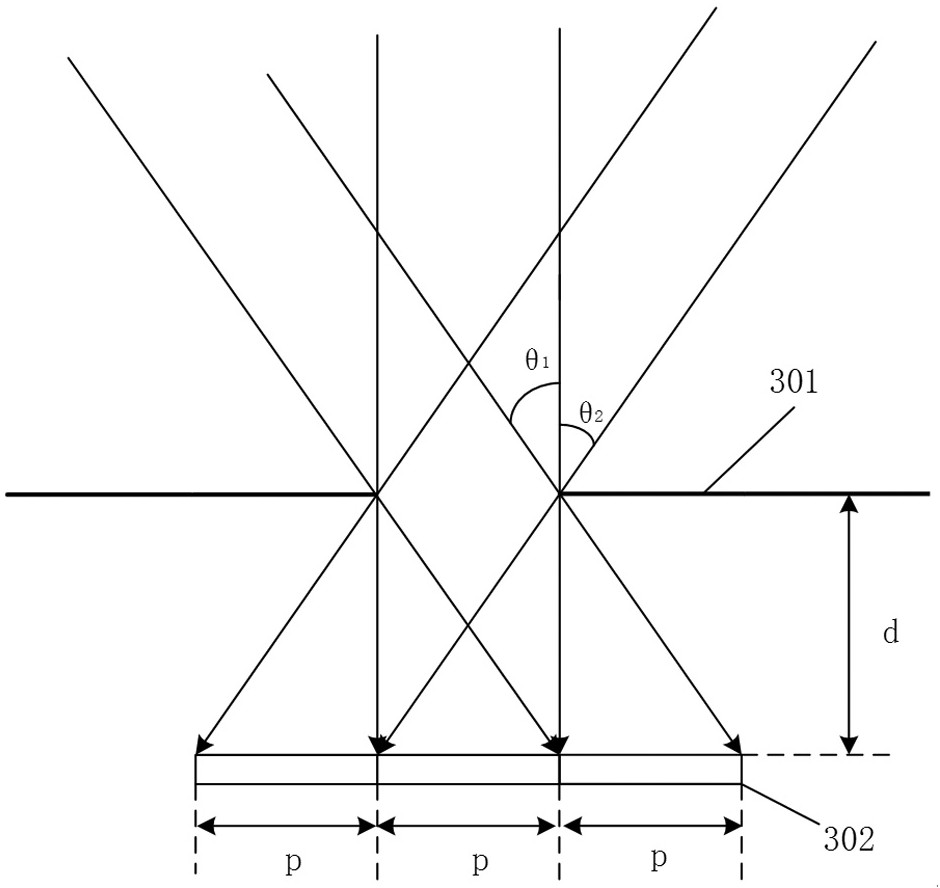

Method used

Image

Examples

Embodiment Construction

[0034] The present invention discloses a Micro-LED manufacturing method for improving the luminous balance of sub-pixels, and those skilled in the art can learn from the content of this article and appropriately improve the technical details for implementation. It should be particularly pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are deemed to be included in the present invention. The method and application of the present invention have been described through the preferred embodiments, and it is obvious that relevant persons can make changes or appropriate changes and combinations of the methods and applications described herein without departing from the content, spirit and scope of the present invention to achieve and Apply the technology of the present invention.

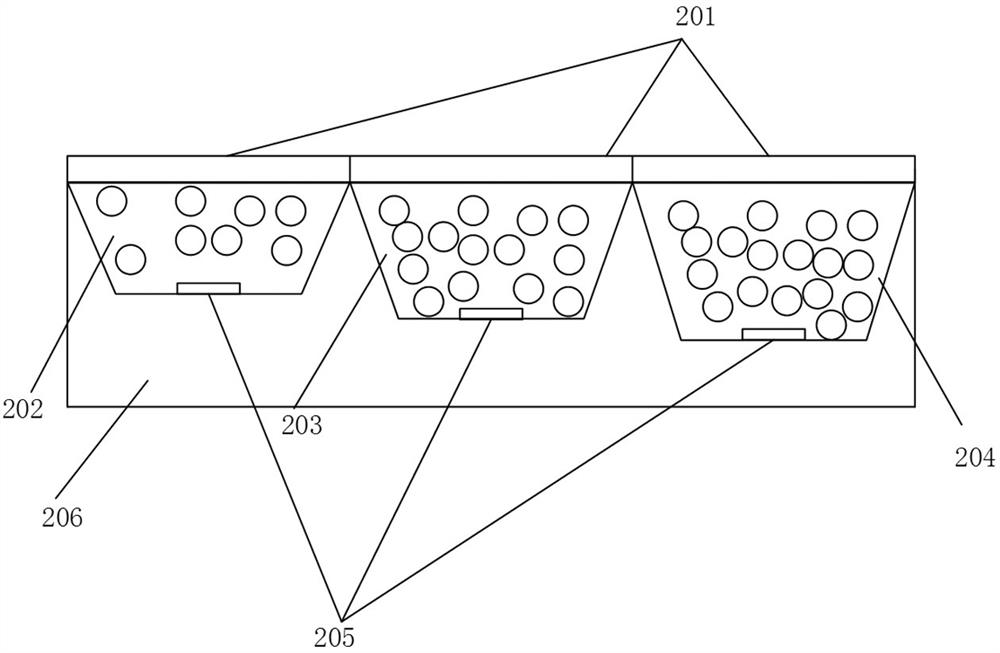

[0035] The quantum dots corresponding to the sub-pixels of different colors absorb different energy of light with the same brightness, which lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com