Flavored chicken ribs and making process thereof

A technology for making chicken ribs, which is applied in food science and other fields, can solve the problems of fishy smell, waste, and affect the appearance of products, and achieve the effect of good taste, beautiful appearance, and enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

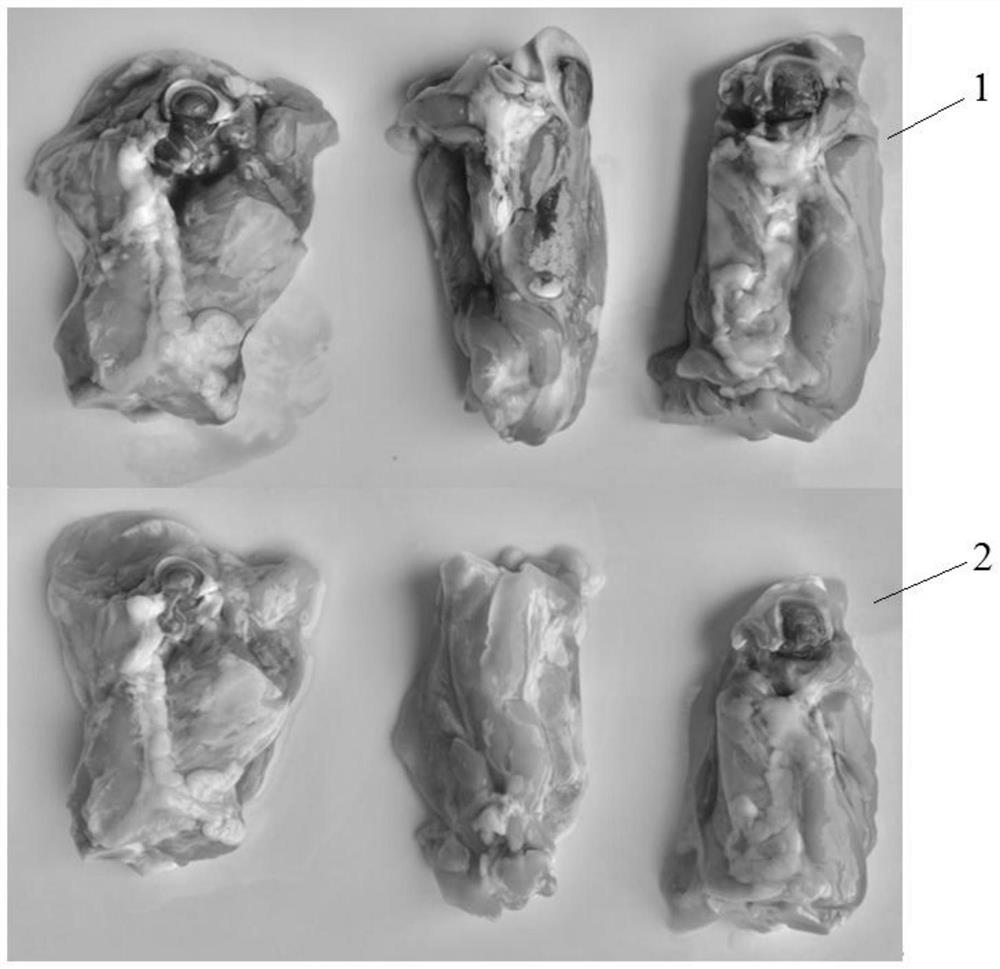

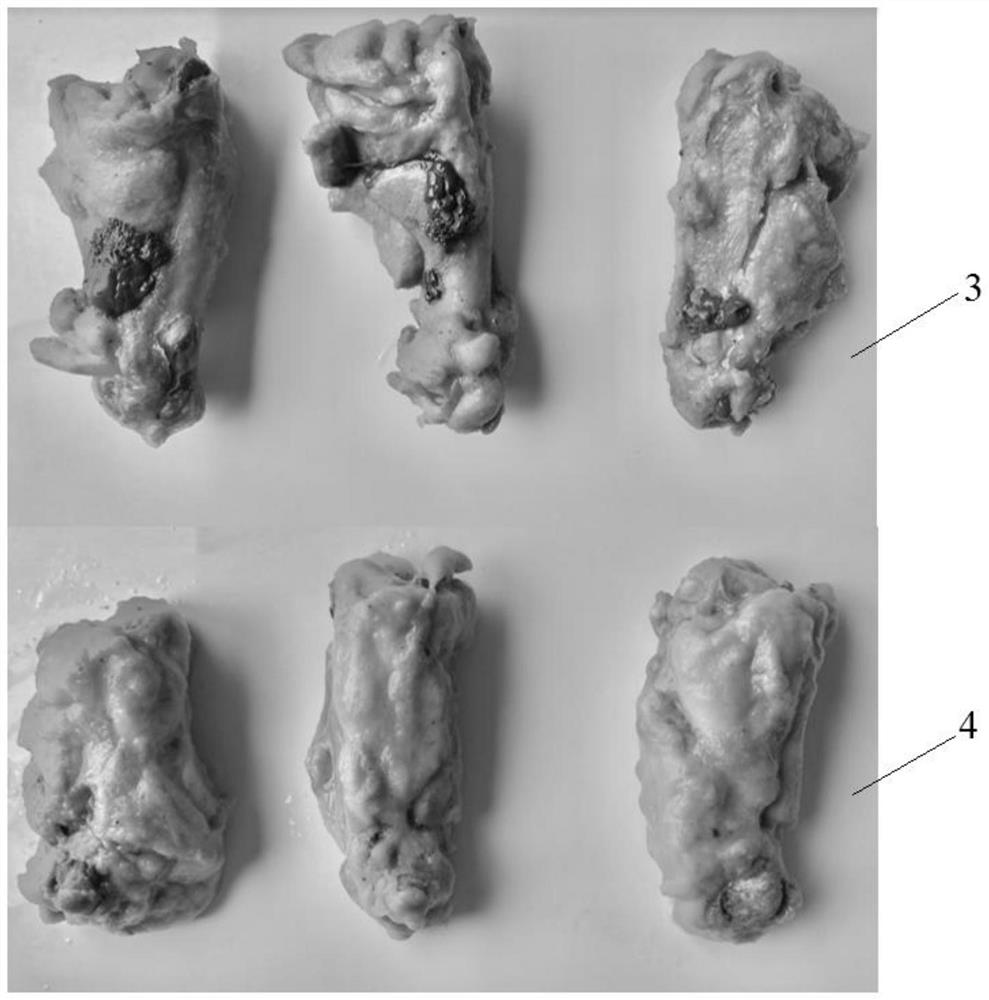

Image

Examples

Embodiment 1

[0063] A kind of flavored chicken ribs provided by Example 1 of the present invention is prepared from the following raw materials in parts by weight:

[0064] 750 parts of chicken ribs, 3 parts of compound phosphate, 45 parts of seasoning, 85 parts of spice, 22 parts of compound starch, 50 parts of water;

[0065] Wherein, the compound phosphate is composed of sodium tripolyphosphate, sodium hexametaphosphate and sodium pyrophosphate, and the ratio of parts by weight between the three is 8:4:3; the spice is made of frozen minced garlic , white pepper powder, ginger paste and chicken powder are compounded, and the ratio of parts by weight between the four is 70:3:6:7; the compound starch is compounded by acetate starch, edible salt and rice flour , and the ratio of parts by weight among the three is 90:5.5:3; the seasoning is compounded from light soy sauce, salt, white sugar, cooking wine and oil consumption, and the parts by weight between the five The ratio is 15:3:10:12:1...

Embodiment 2

[0073] A kind of flavored chicken ribs provided by Example 2 of the present invention is prepared from the following raw materials in parts by weight:

[0074] 700 parts of chicken ribs, 4 parts of compound phosphate, 43 parts of seasoning, 96 parts of spice, 20 parts of compound starch, 60 parts of water;

[0075] Wherein, the compound phosphate is composed of sodium tripolyphosphate, sodium hexametaphosphate and sodium pyrophosphate, and the ratio of parts by weight between the three is 8:4:3; the spice is made of frozen minced garlic , white pepper powder, ginger paste and chicken powder are compounded, and the ratio of parts by weight between the four is 70:3:6:7; the compound starch is compounded by acetate starch, edible salt and rice flour , and the ratio of parts by weight among the three is 90:5.5:3; the seasoning is compounded from light soy sauce, salt, white sugar, cooking wine and oil consumption, and the parts by weight between the five The ratio is 15:3:10:12:1...

Embodiment 3

[0078] A kind of flavored chicken ribs provided by Example 3 of the present invention is prepared from the following raw materials in parts by weight:

[0079] 800 parts of chicken ribs, 2 parts of compound phosphate, 61 parts of seasoning, 76 parts of spice, 24 parts of compound starch, 40 parts of water;

[0080] Wherein, the compound phosphate is composed of sodium tripolyphosphate, sodium hexametaphosphate and sodium pyrophosphate, and the ratio of parts by weight between the three is 8:4:3; the spice is made of frozen minced garlic , white pepper powder, ginger paste and chicken powder are compounded, and the ratio of parts by weight between the four is 70:3:6:7; the compound starch is compounded by acetate starch, edible salt and rice flour , and the ratio of parts by weight among the three is 90:5.5:3; the seasoning is compounded from light soy sauce, salt, white sugar, cooking wine and oil consumption, and the parts by weight between the five The ratio is 15:3:10:12:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com