Plastering construction method for large-area carborundum wear-resistant ground by driving type machine

A construction method, emery technology, applied in separation methods, metal processing equipment, cleaning methods and appliances, etc., can solve problems such as cracks on the concrete surface, increase construction costs, and affect later use, so as to achieve smooth surfaces, reduce investment, and shorten the cost. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

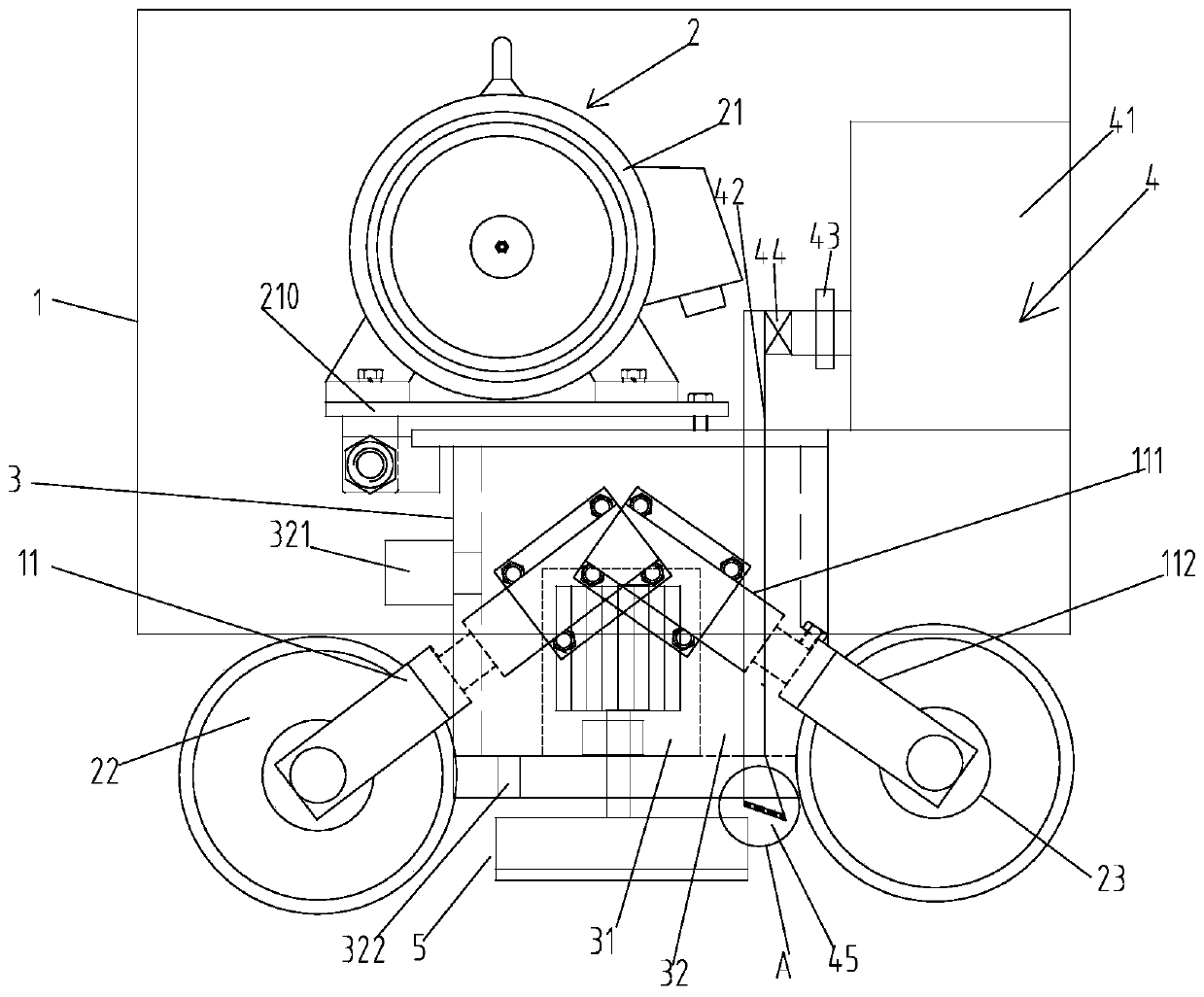

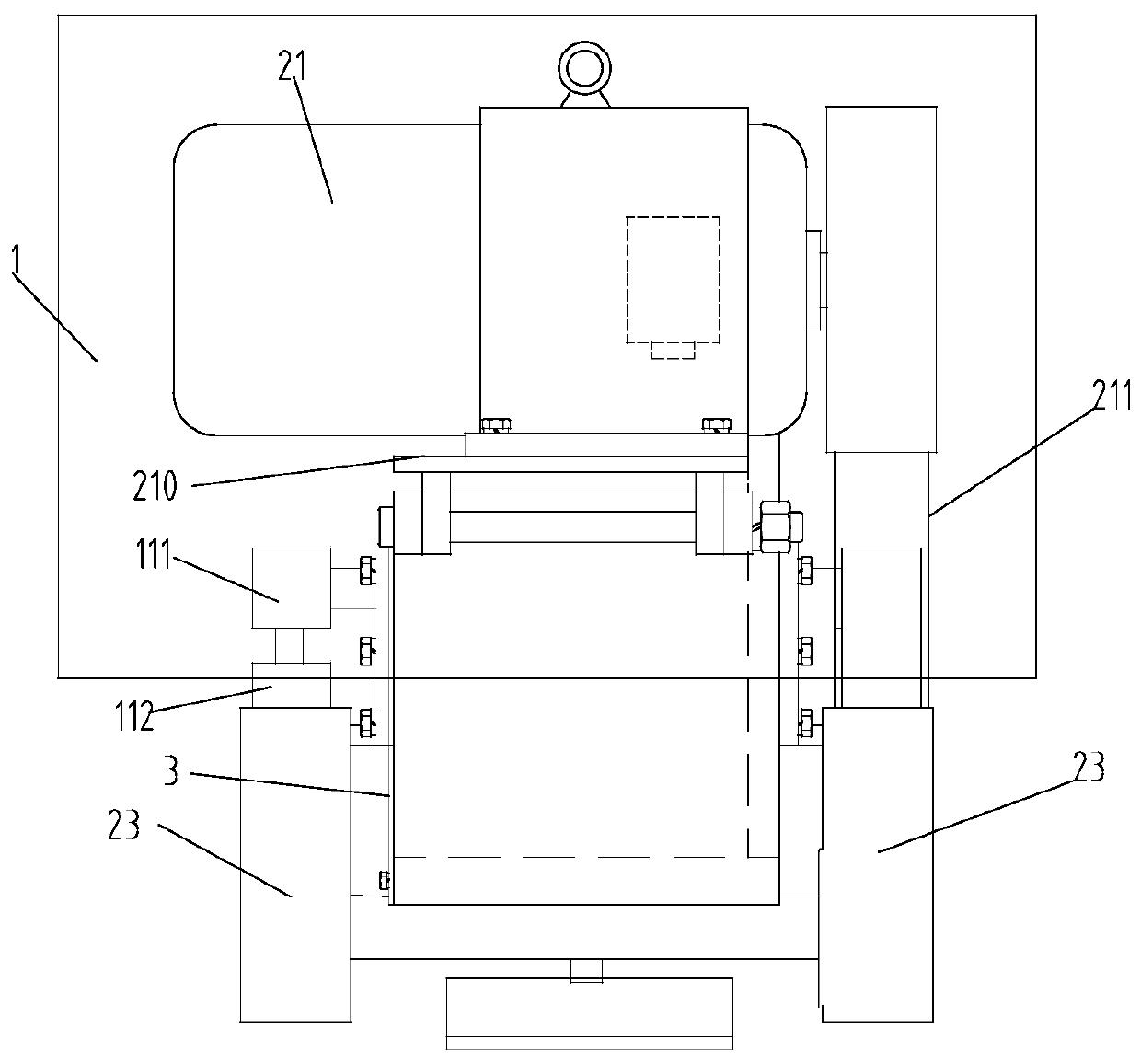

[0025] see Figure 1-4 A large-area corundum wear-resistant ground driving type mechanical plastering construction method shown includes the following steps: when in use, the box body 1 is moved, the drive assembly 2 is started, and the front travel wheel 22 and the rear travel wheel 23 are driven by the drive motor 21 to move ;

[0026] When moving to the position that needs grinding operation, start grinding motor 51 drives grinding disc 53 to rotate by motor connecting shaft 52, and grinding layer 54 grinds close to the ground;

[0027] During the grinding process, the dust generated by grinding is absorbed by the exhaust pipe 322 of the vacuum pump 321;

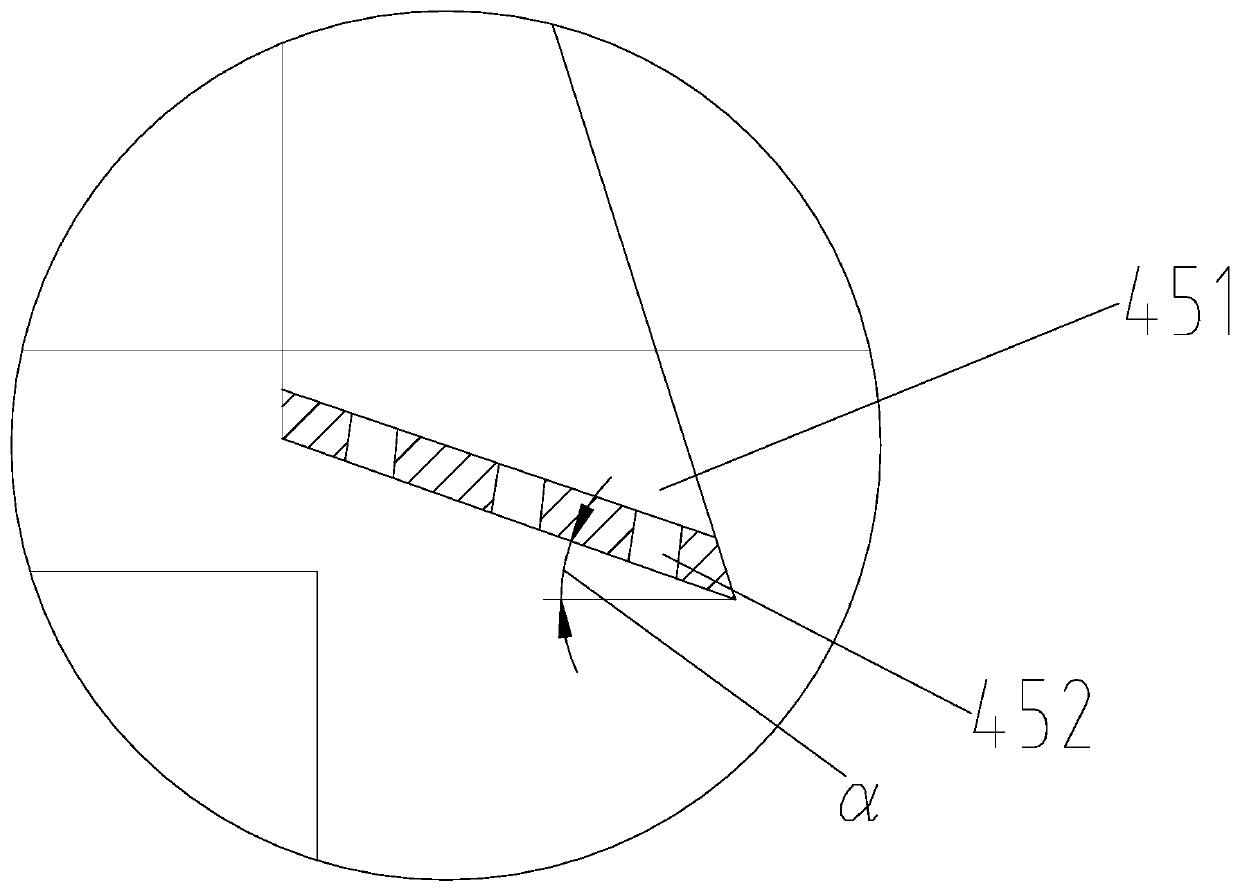

[0028] By activating the water pump 43, water is passed through the nozzle 45 to further remove the dust. The inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com