Indoor ground water supply pipeline concealed laying and groove pressing tool and use method thereof

A technology for water supply pipes and indoor floors, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., to achieve the effects of low production cost, convenient production, and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The hidden pressure groove tool for indoor ground water supply pipeline of the present invention comprises two steel pipes and four supporting plates.

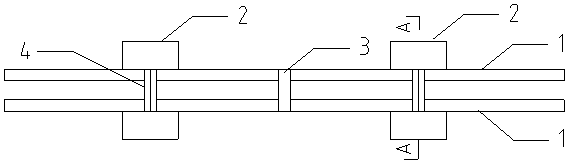

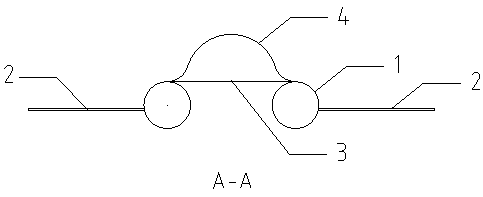

[0035] see now figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a grooving tool according to an embodiment of the present invention, figure 2 for figure 1 Sectional view of A-A in Fig. As shown in the figure, the two steel pipes 1 each have a length of 2m, are arranged in parallel, and have a mutual spacing of 50mm; A handle 4 is solidly welded on the surface of the steel plate 3 at both ends; the steel pipe 1 is a DN50 steel pipe. The steel plate 3 is a 50*150*2mm steel plate. The handle 4 is an arc-shaped handle made of round steel with a diameter of 8 mm. Described handle can also be made into Π shape handle.

[0036] The four supporting plates 2 are 100*200*2mm steel plates, which are fixedly welded on the outer sides of the two parallel steel pipes where the handle is located in a ...

Embodiment 2

[0038] A method for using a concealed pressure groove tool for indoor ground water supply pipelines. The diameter of the steel pipe 1 needs to be determined according to the designed pressure groove width, and the diameter of the steel pipe 1 is determined according to the designed pressure groove depth, and the bottom end of the steel pipe 1 is determined. The distance processing to the lower surface of supporting plate 2 is made as the embossing tool of embodiment 1, comprises the following steps during use:

[0039] a. Before concrete pouring, use thin iron wire to locate the position where the water supply pipe needs to be pressed.

[0040] b. After the initial setting of the concrete has a certain strength, after 4-6 hours, grasp the handle 4 of the grooving tool with your hands to make the grooving, and use the gravity of the steel pipe 1 to press the groove from one end of the building to the other end, so that the supporting plate 2 The lower surface of the floor coinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com