High-precision intelligent metal plate shearing machine for sheet metal plates

A high-precision, shearing machine technology, applied in the field of sheet metal manufacturing, can solve the problems of manual injury of cutting knives, adverse effects of sheet cutting quality, stuck in rings, etc., and achieve the effect of improving cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

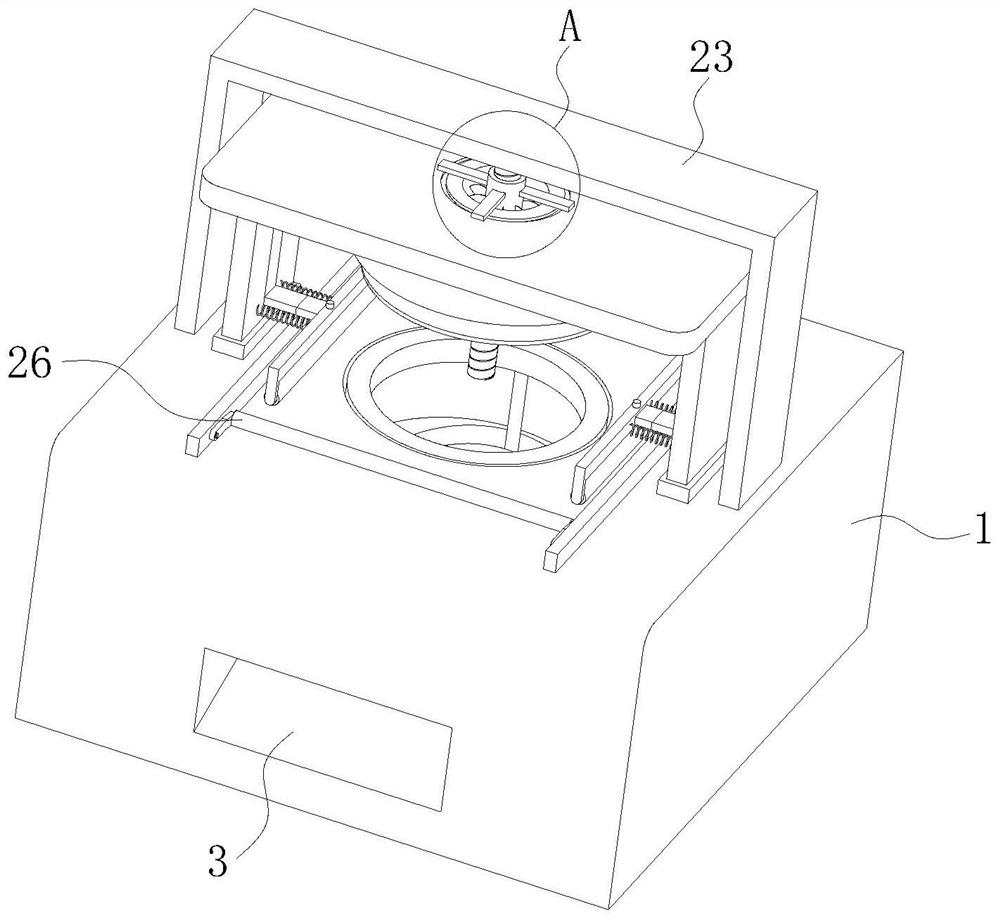

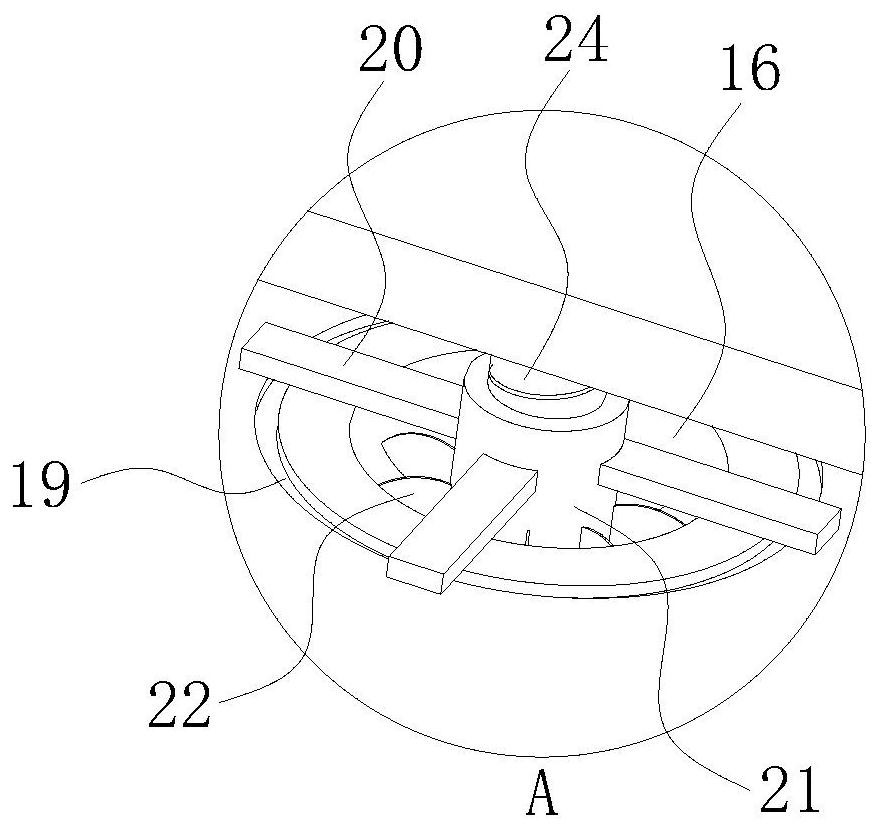

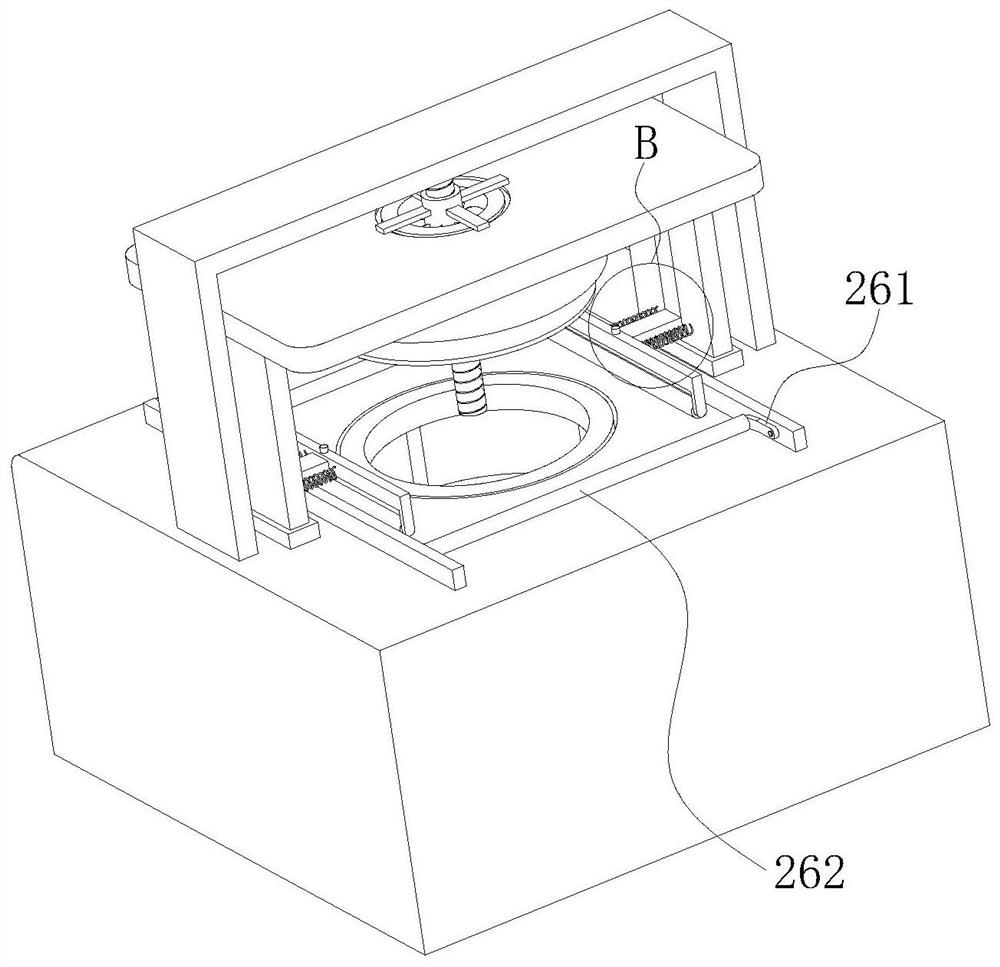

[0030] Such as Figure 1 to Figure 7As shown, the present embodiment provides a high-precision intelligent shearing machine for sheet metal, including a base 1 , the upper surface of which is horizontal and provided with a vertical circular groove 2 . A chute 3 communicating with the circular groove 2 is opened on the side of the base 1 . The bottom surface of the chute 3 is provided with an annular receiving groove 4 coincident with the axis of the circular groove 2 . The bottom surface of the annular receiving groove 4 is vertically provided with a plurality of chute 5 , and a lifting rod 6 is slidably fitted in the chute 5 . A supporting ring 7 cooperating with the annular receiving groove 4 is fixedly installed horizontally on the top of the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap