A servo tool magazine based on machine vision tool arm positioning and its tool change control method

A technology of machine vision and tool magazine, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., to achieve stable work, ensure replacement accuracy, and avoid narrow applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

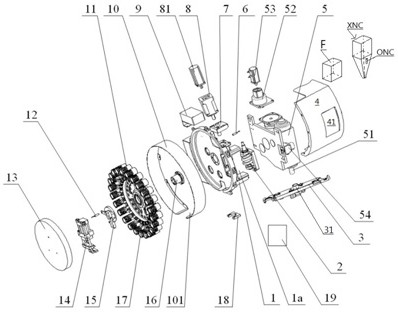

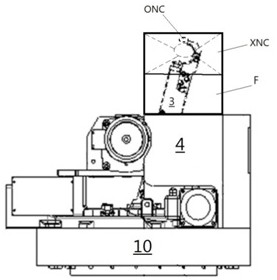

[0071] Such as Figure 1-4 As shown, a servo tool magazine includes: tool magazine body 1, cam mechanism 2, knife arm structure 3,

[0072] ATC shield 4, ATC tool changing mechanism 5, ATC reducer 52, ATC servo motor 53, cam positioning sensor 6, tool magazine reducer fixed

[0073] Seat 7, tool magazine reducer 8, tool magazine servo motor 81, control box 9, tool magazine rear cover 10, disc cutter head unit 11, origin sensor 12, tool magazine front cover 13, knife reversing cylinder group 14. Knife reversing micro switch 15, cutter head spindle 16, knife holder structure 17, reversing knife positioning seat 18, servo driver 19;

[0074] Wherein, the cam mechanism 2 is arranged at the rear portion of the tool magazine body 1, and the cam positioning sensor 6 is arranged at the rear portion of the tool magazine body 1 and is positioned above the cam mechanism 2. unit 11 transmission connection,

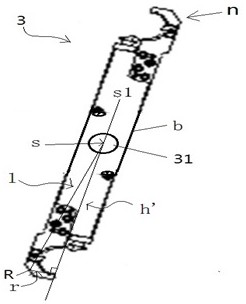

[0075] The knife arm structure 3 has a drive shaft sleeve 31 that is sheathed ...

Embodiment 2

[0089] Such as Figure 4 As shown, the present invention also provides a tool change control method for a servo tool magazine, comprising the following steps:

[0090] (1) Calibrate the position of the origin of the knife arm structure 3: set a point in the middle of the handle part n as the reference point R, connect the reference point R and the rotational symmetry point s, and pass the reference point R to make the symmetry The vertical line of the axis s1 is used to obtain the reference vertical segment r between the vertical foot and the reference point; start the ATC servo motor 53 at the rated speed to drive the knife arm structure 3 to rotate, when the origin sensor 12 detects that the knife arm structure 3 returns to the initial position , the ATC servo motor continues to drive the knife arm 3 structure to rotate for 30s at the lowest speed of 1r / min, then stops the ATC servo motor, and then reverses the ATC servo motor 53 at the lowest speed until the origin sensor 1...

Embodiment 3

[0117] In the step S1-S3.2 in the embodiment 2, the corresponding angle difference is obtained every time the difference is obtained, and the actual angle difference measured by the actual angle monitoring encoder 54 of the knife arm is also used as an average value, and the average value is used as a new value. The comparison object for adjusting the position of the knife arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com